Vibrating diaphragm and preparation method thereof

An intermediate layer, honeycomb hole technology, applied in diaphragm structure, frequency/direction characteristic device, sensor, etc., can solve the problems of low agility, poor high frequency performance, large dome quality, etc., and achieve good frequency response characteristics , The effect of sound pressure level improvement and high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

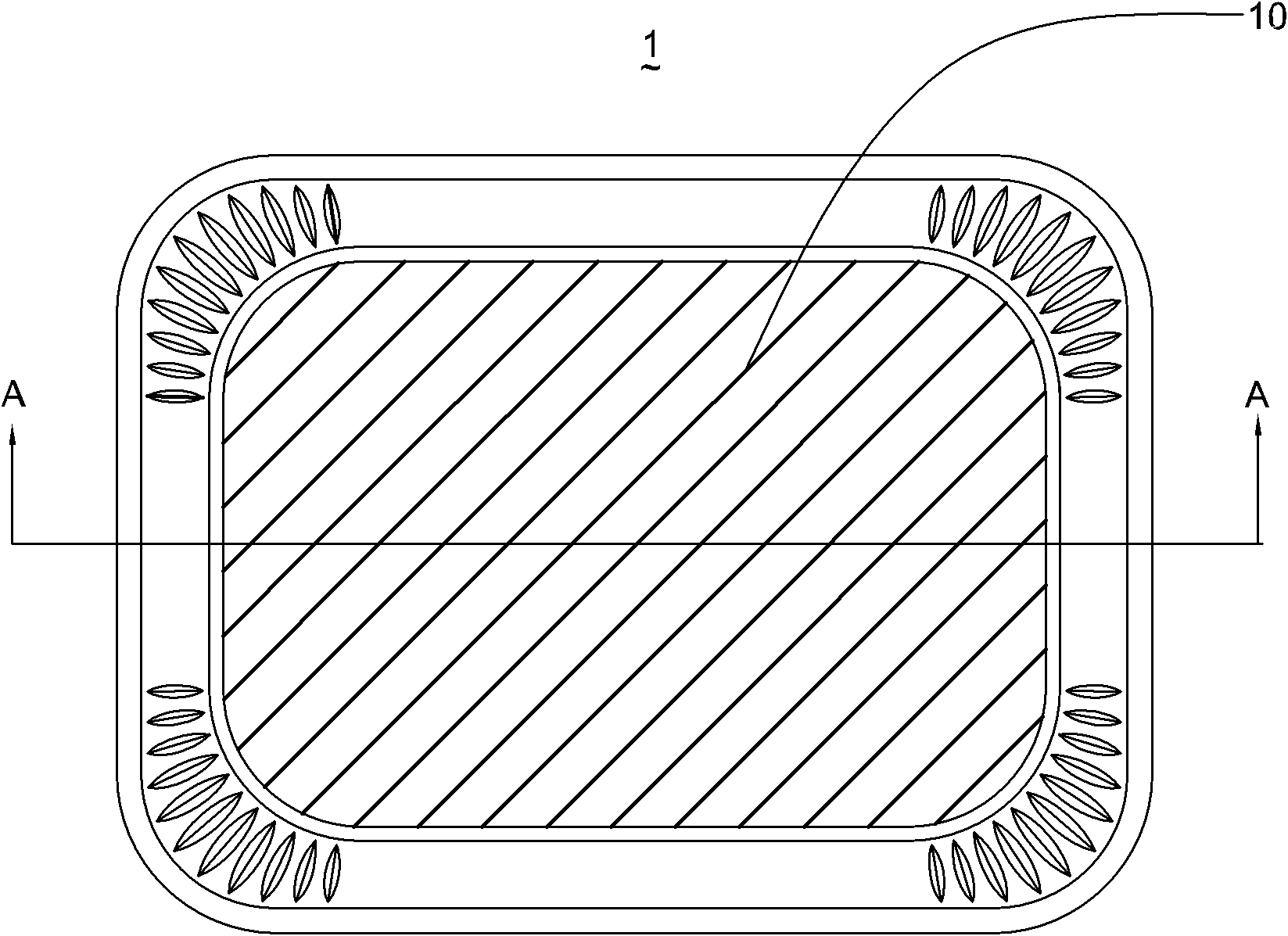

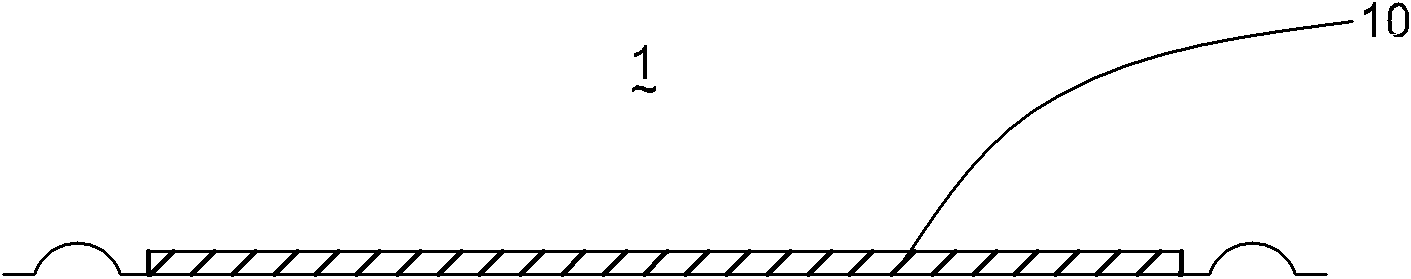

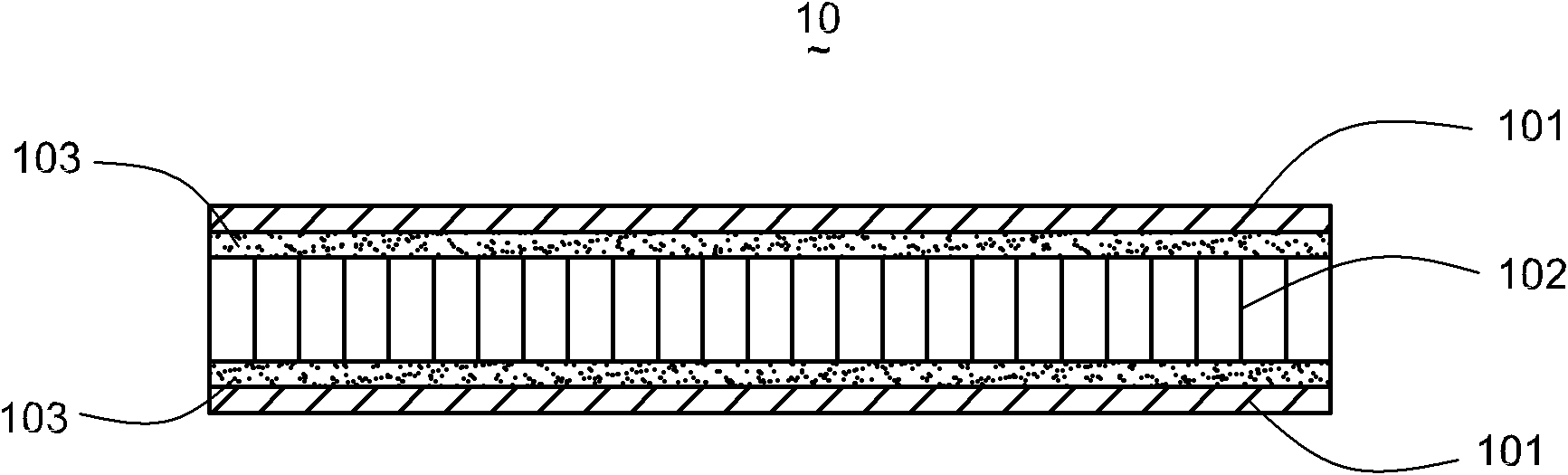

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a diaphragm 1, the diaphragm 1 includes a dome top 10, the dome top 10 includes a middle layer 102 made of aluminum honeycomb material, and it also includes a Plywood layers 101 on the upper and lower surfaces.

[0022] Such as image 3 and Figure 4 As shown, the honeycomb holes 1021 in the middle layer 102 run through the upper and lower surfaces of the middle layer 102 and are vertical to the dome 10. The honeycomb holes are regular polygons with a wall thickness of 0.02 mm to 1 mm and a side length of 0.1 mm to 20 mm. mm, the height is 0.1 mm to 10 mm, and the aluminum honeycomb density of the middle layer 102 is greater than or equal to 20 kg / m3 and less than or equal to 600 kg / m3. Compared with the previous solid diaphragm or the diaphragm made of gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com