Industrial robot with weight balancing system

An industrial robot and gravity balance technology, which is applied in the direction of robots, manipulators, manufacturing tools, etc., can solve the problem of expensive mass balance system, achieve the effect of saving materials, saving costs, and simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

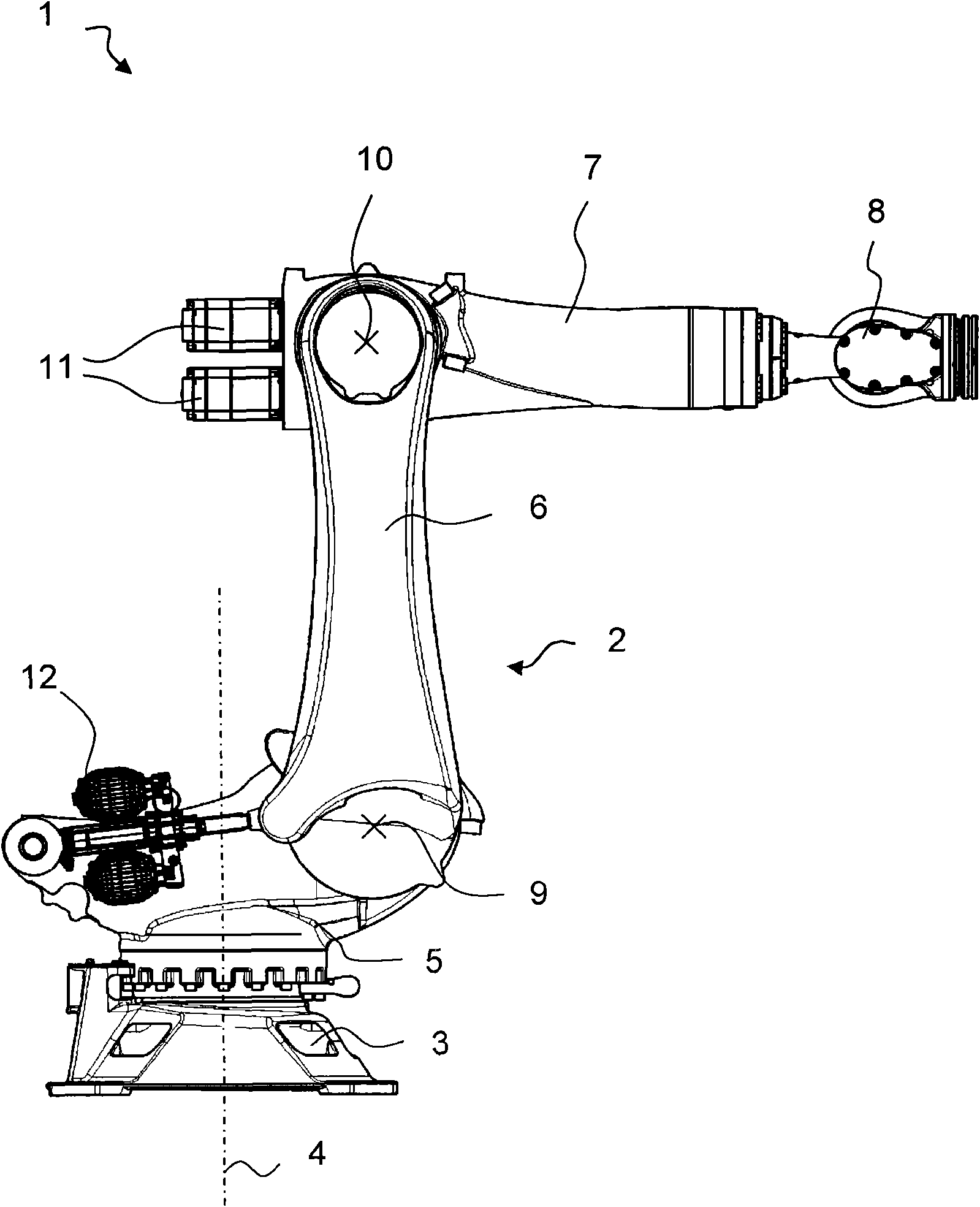

[0022] figure 1 An industrial robot 1 is shown in side view with a robot arm 2 which is designed for relatively large loads, in particular loads greater than 90 kg.

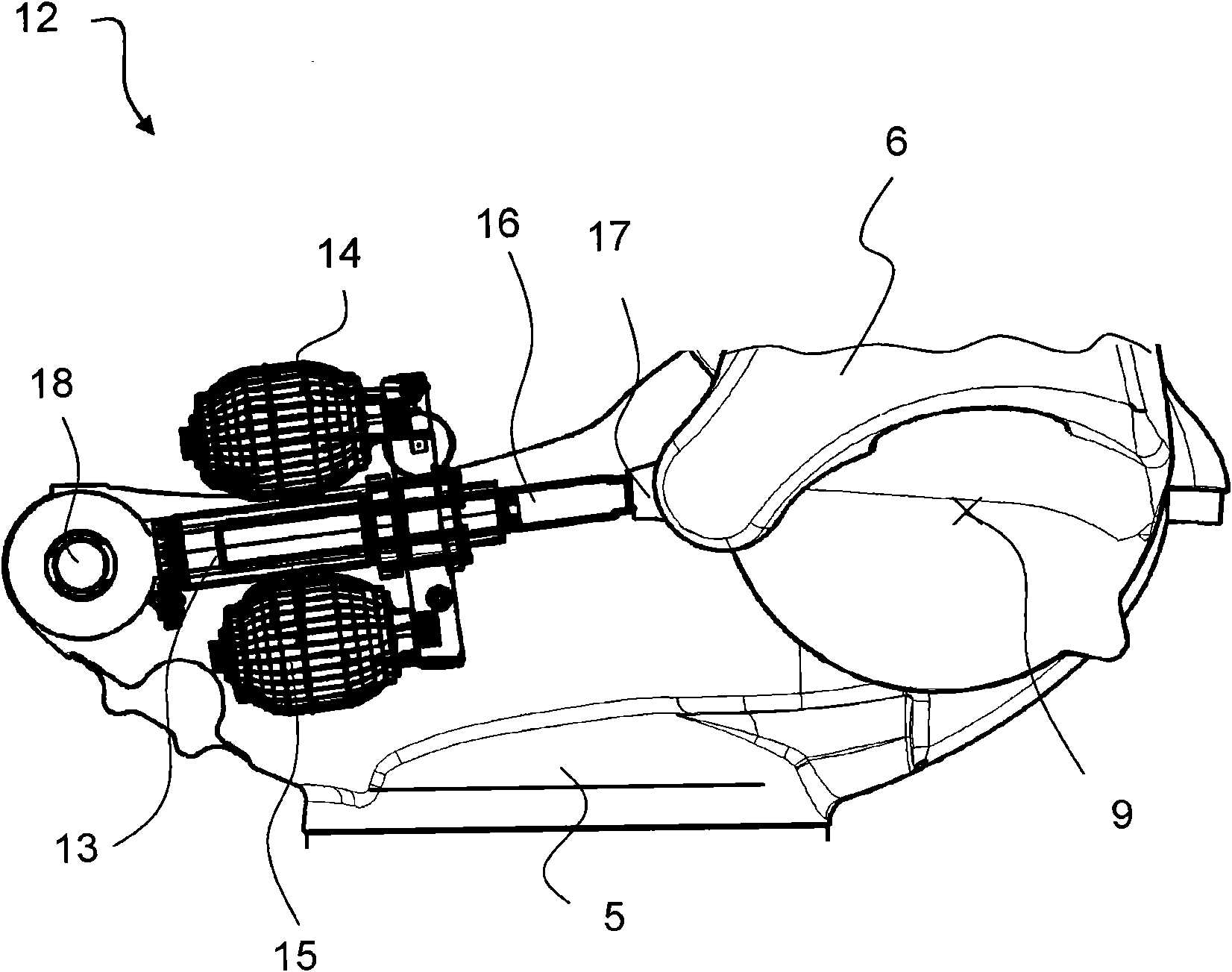

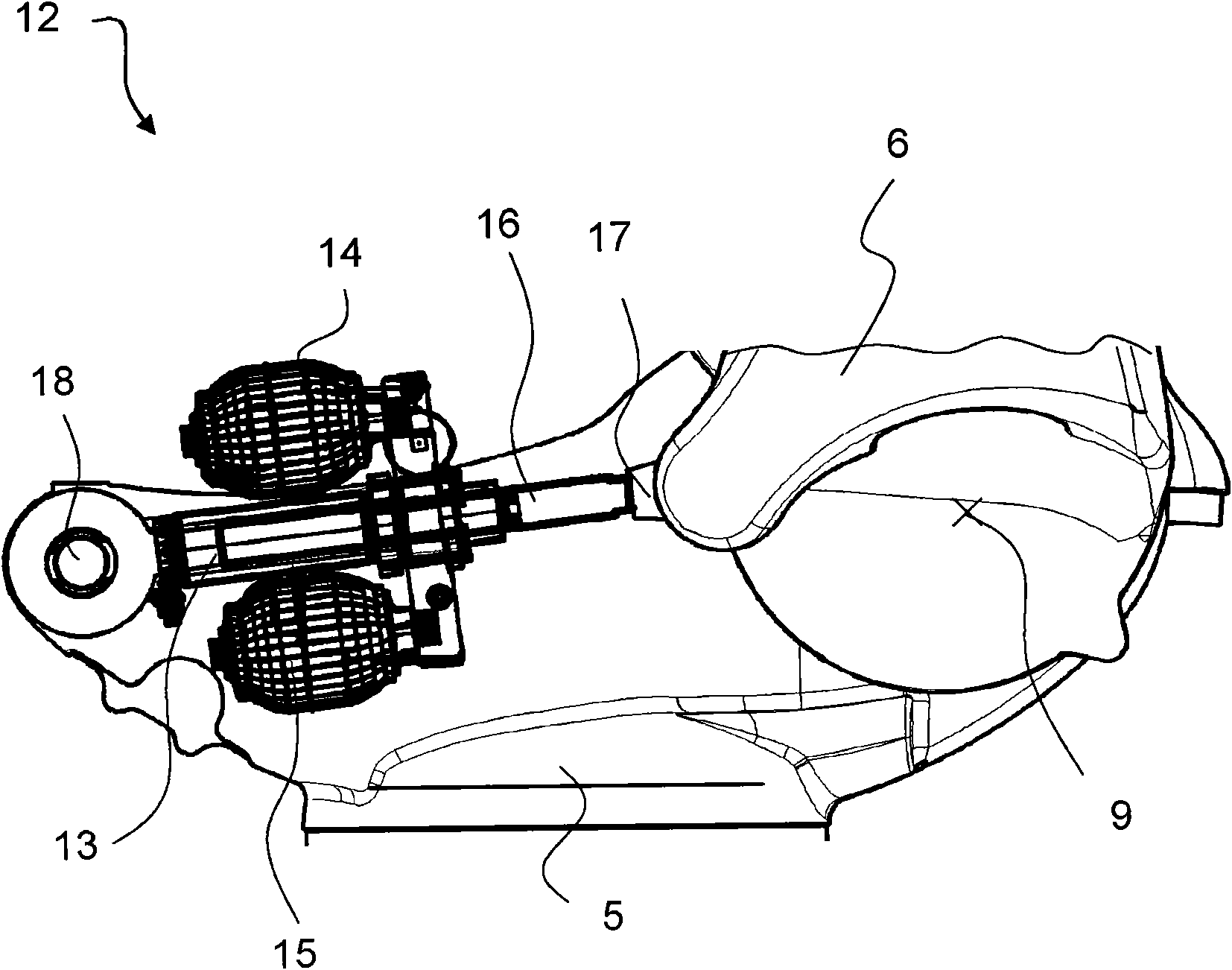

[0023] In the present exemplary embodiment, the robot arm 2 comprises a stationary or movable support 3 and a turntable 5 mounted rotatably relative to the support 3 about a vertically extending axis 4 (also referred to as axis 1 ). Furthermore, in the present exemplary embodiment, the robot arm 2 of the industrial robot 1 also has a swing arm 6 , a boom 7 and a preferably multi-axis robot hand 8 . The rocker arm 6 is mounted at its lower end (for example in a rocker arm bearing head (not shown in detail)) so as to pivot about a horizontal axis 9 , also referred to as axis 2 , on the turntable 5 . Likewise, the boom 7 is also preferably mounted pivotably about a horizontal axis 10 on the upper end of the rocker arm 6 . Cantilever 7 preferably with its three axes (in figure 1 Not shown in detail in ) carries th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com