Detection robot for underground rescue of pressurized type coal mine

An underground rescue and robot technology, applied in the direction of manipulators, motor vehicles, mining equipment, etc., can solve the problems of unfavorable laying of optical fibers, unfavorable casing airtightness, and affecting mechanical efficiency, etc., to achieve light weight, safe box, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

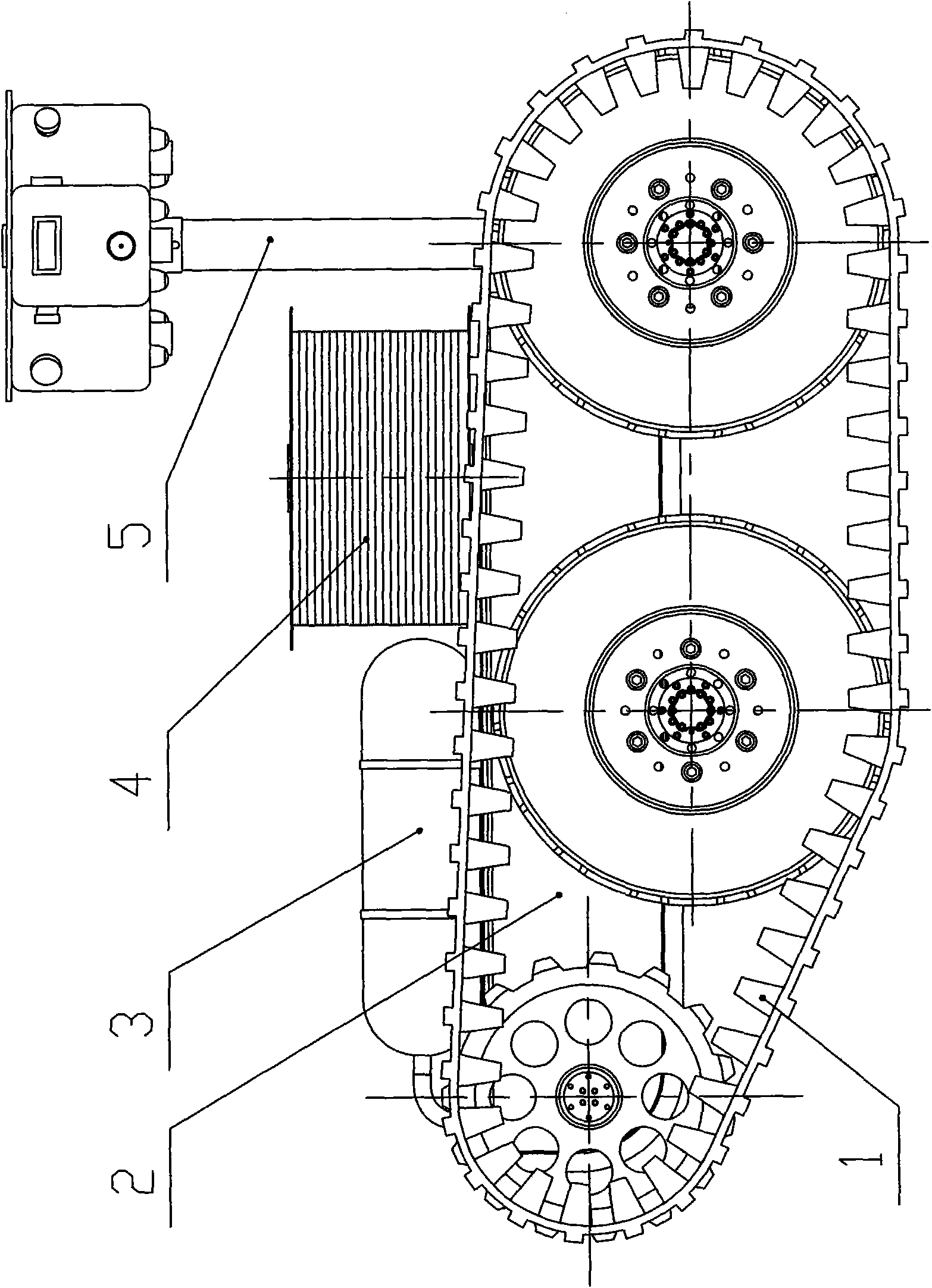

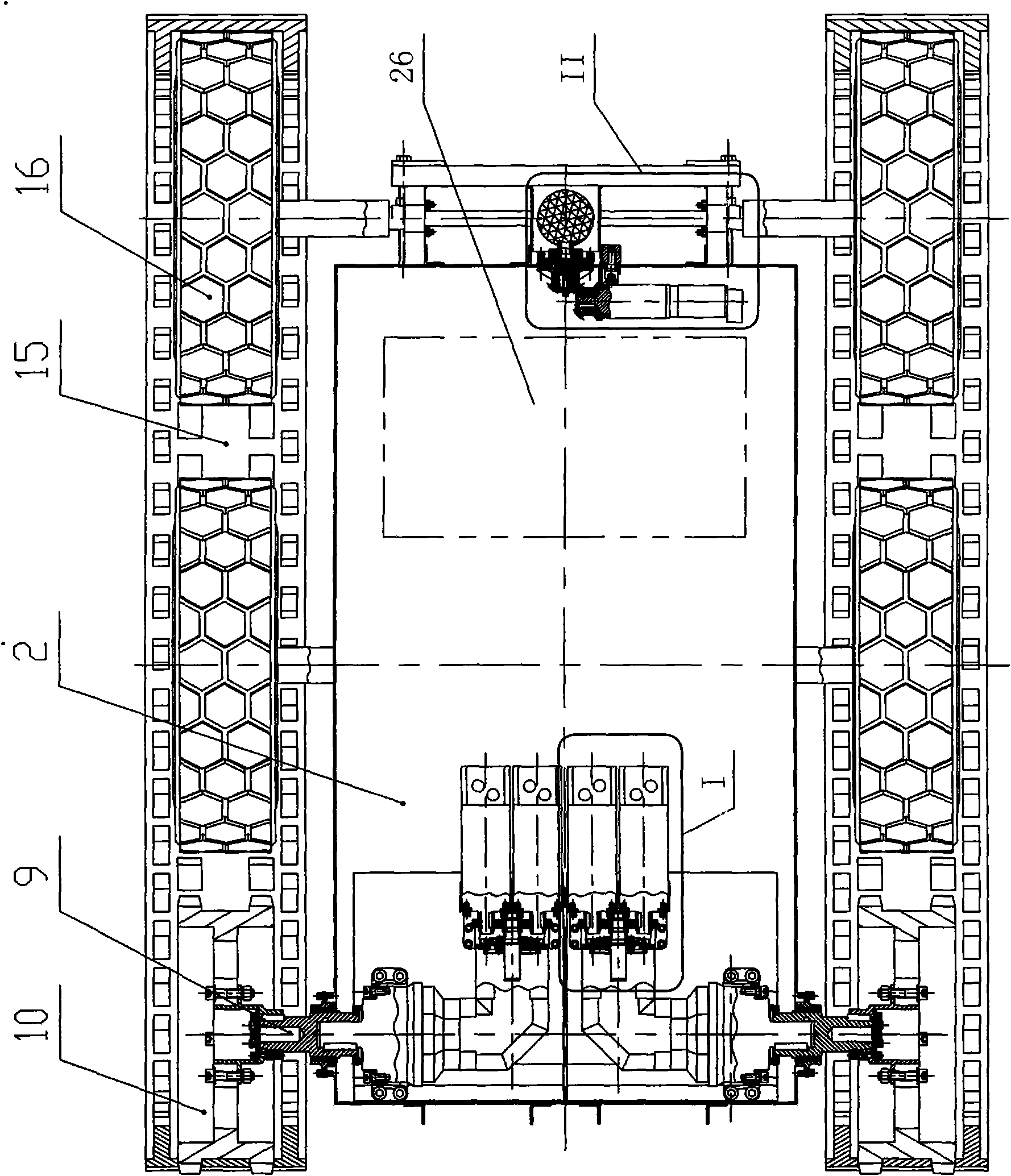

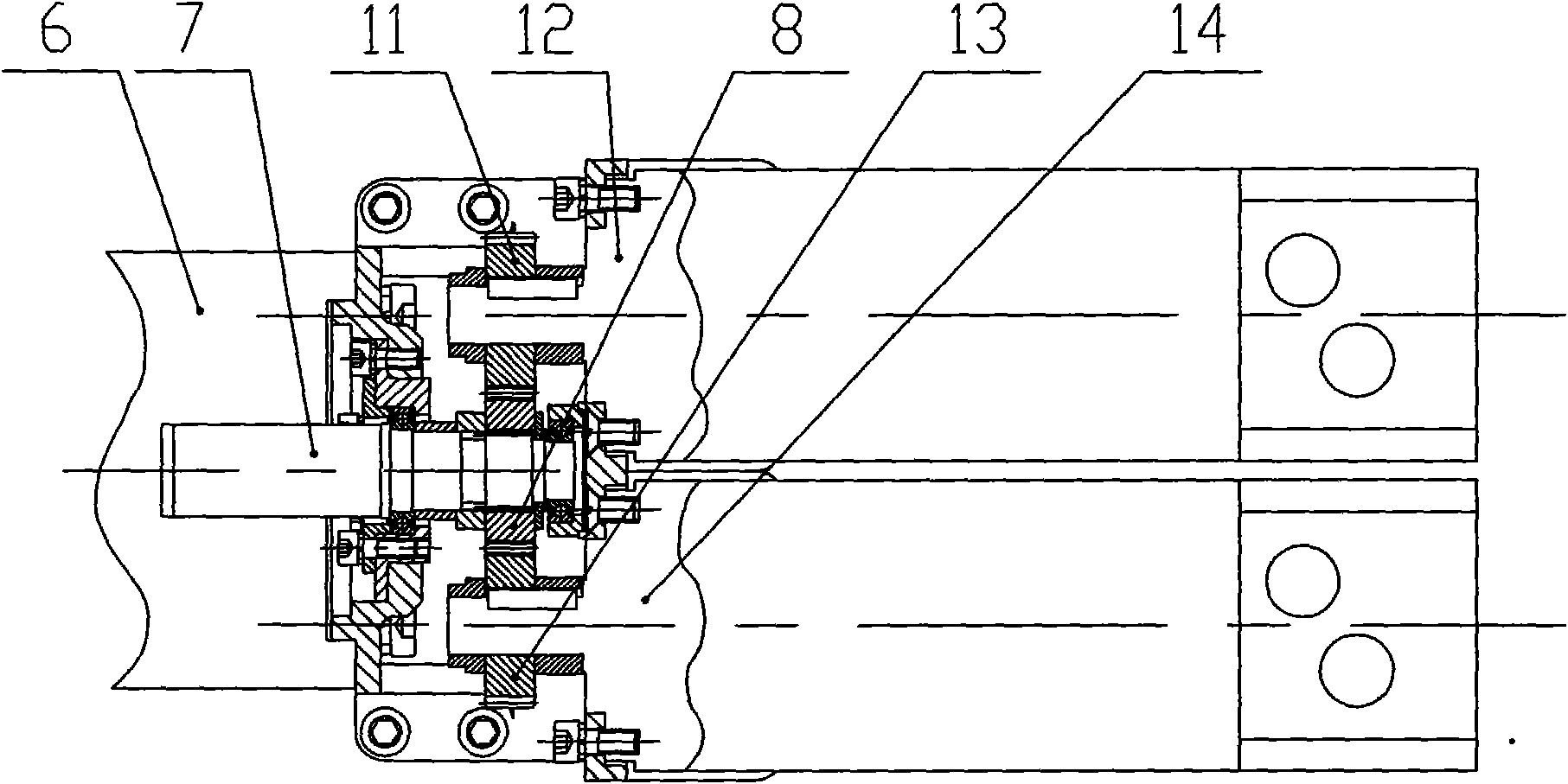

[0024] Embodiment 1: as figure 1 , figure 2 As shown, the present invention includes a positive pressure shell type explosion-proof box 2, a walking mechanism 1 placed symmetrically on both sides of the explosion-proof box, an independent driving mechanism and an industrial computer, a lifting mechanism 5 and an optical fiber placed in the explosion-proof box 2 The winding mechanism 4 constitutes a modular structure, the traveling mechanism 1 is connected with the driving mechanism, the optical fiber winding mechanism 4 is placed on the upper part of the carriage body 2, and is independent from the carriage body 2; the lifting mechanism 5 is provided with various detection sensors , the industrial computer is connected to the drive mechanism and each detection sensor respectively, and one end of the optical fiber is connected to the control end. The two drive mechanisms are installed symmetrically to drive the drive wheels 10 on both sides of the box body 2 respectively; each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com