Elevator mechanism of automatic stacking device and control method

A technology of a lifting mechanism and a stacking device, which is applied in the field of automatic stacking devices for bricks, can solve problems such as low brick stacking quality, inaccurate positioning, and complicated mechanical structure, so as to ensure stacking quality, stable movement, and positioning accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

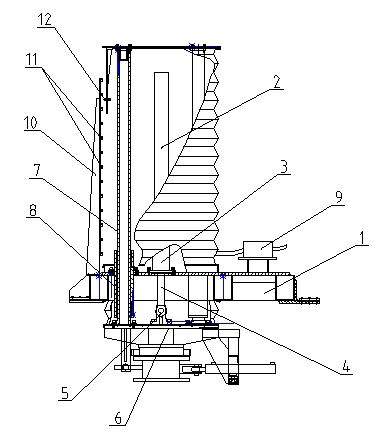

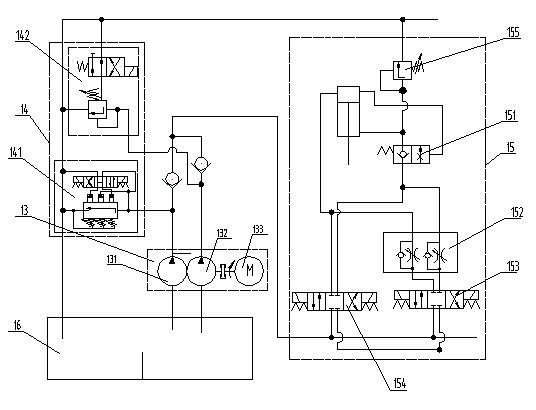

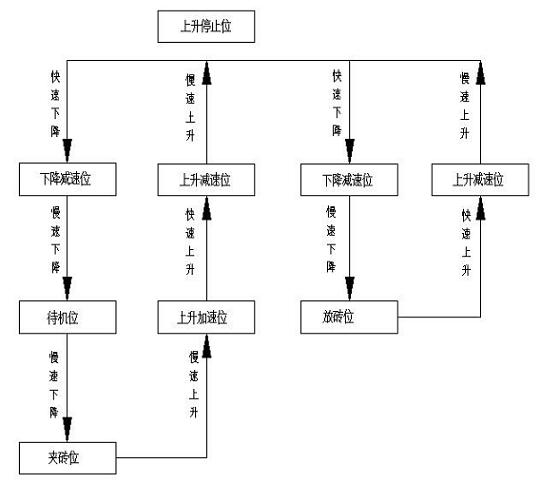

[0020] like figure 1 As shown, the lifting mechanism of an automatic palletizing device is arranged on the horizontal walking frame 1, the cylinder body 3 of the lifting oil cylinder 2 is fixed on the horizontal walking frame 1, and the piston rod 4 of the lifting oil cylinder 2 is connected to the connecting frame through the hinge support 5. 6 connection, the connecting frame 6 is used to install the manipulator mechanism of the palletizing device. The guide post 7 provided on the connecting frame 6 is located in the guide sleeve 8 on the horizontal walking frame 1, and the guide post slides in the guide sleeve on the horizontal walking frame. Lifting cylinder 2 drives connecting frame 6 to lift when stretching, and is guided by guide column 7 and guide sleeve 8, guarantees connecting frame 6 vertical and steady motion. Also comprise lifting control device 9 and position induction mechanism, position induction mechanism comprises induction ruler 10 and inductor 12, and indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com