Homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic

A homogeneous material and plasticizable technology, applied in the field of high-temperature wear-resistant refractory materials, can solve problems such as low water absorption and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

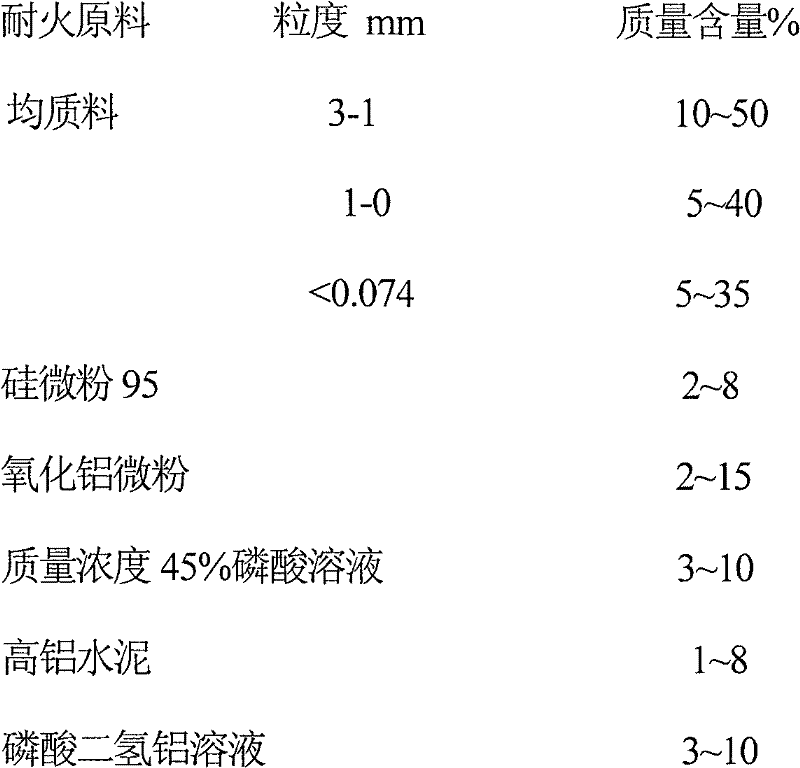

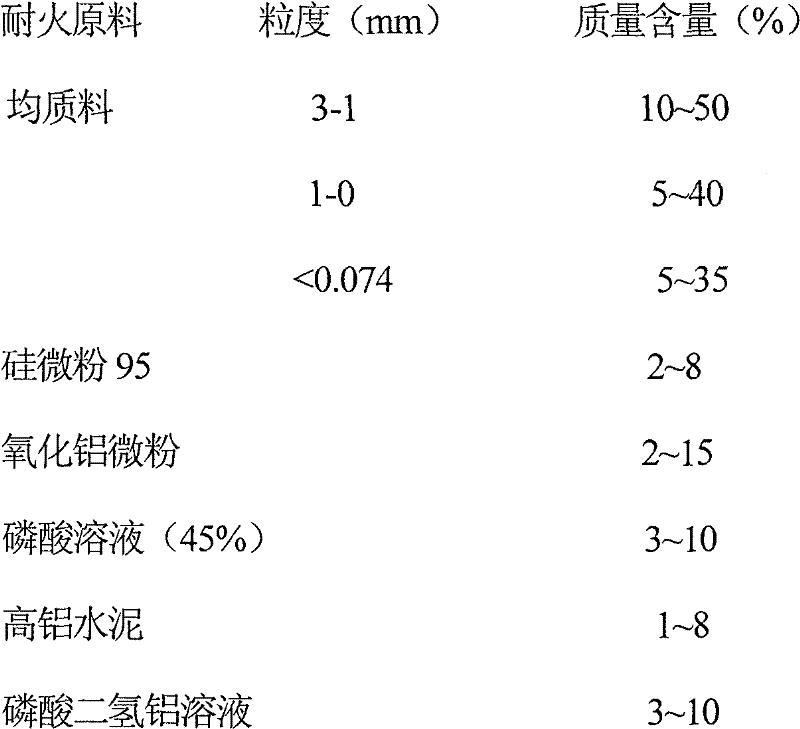

Method used

Image

Examples

Embodiment Construction

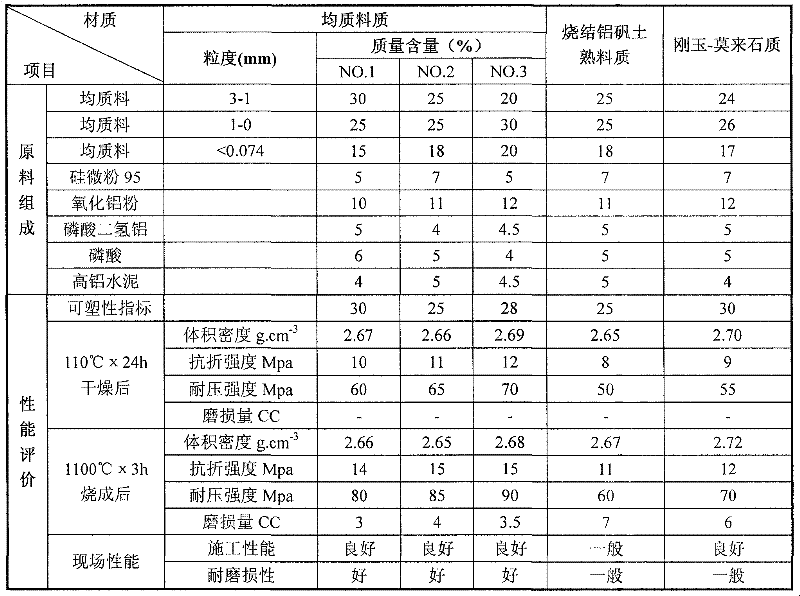

[0012] See Table 1 for examples.

[0013] Table 1 Embodiments of the present invention

[0014]

[0015] After field trials, the present invention uses artificially synthesized homogeneous materials with low water absorption, low porosity and high uniformity to replace traditional sintered bauxite clinker or mixed raw materials of corundum and mullite with high water absorption, high porosity and poor uniformity , developed a corundum-mullite series high wear-resistant plastic, which not only has good construction performance, high strength and good wear resistance, but also has the best field use effect, which is conducive to prolonging the service life of the furnace lining and improving the utilization of high-temperature kilns Efficiency, has a broad market prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com