Melt-out recombined composite aluminum oxide refractory materials

A technology of composite alumina and refractory materials, which is applied in the field of melting and recombining composite αβ or β oxygen, which can solve the problems of high temperature resistance and corrosion resistance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

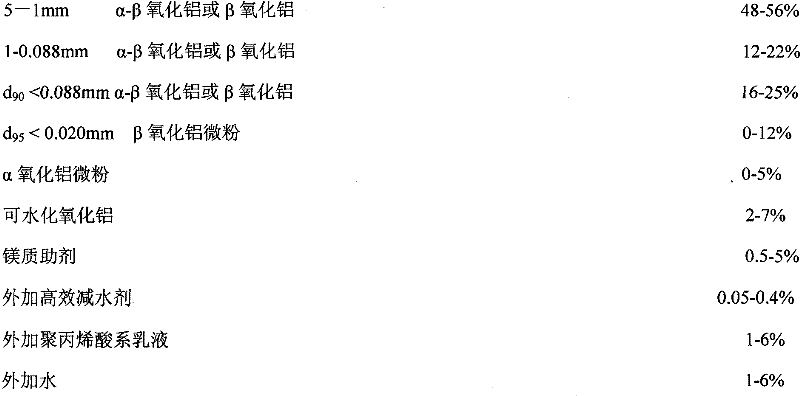

[0044] Use 5-1mm fused αβ alumina 53%, 1-0.088mm fused αβ alumina 17%, d 90 95 95 0.6 >1700°C.

[0045] The manufactured product has good manufacturing performance and extremely excellent high temperature resistance, and the experiment has been successful.

Embodiment 2

[0047] Use 5-1mm fused β-alumina 50%, 1-0.088mm fused β-alumina 20%, d 90 95 12MPa was obtained, which was nearly 200% higher than that of the sample doped with magnesia ; Then heat treatment at 1500°C for 3 hours to obtain a flexural strength of 16MPa, a compressive strength of 80MPa, a firing line change of 0.5%, and a load softening temperature of T 0.6 >1700°C.

[0048] The product produced by the invention has good manufacturing performance and extremely excellent high temperature resistance, and is suitable for use as refractory materials such as large-scale and special-shaped refractory products for the upper structure of a glass furnace and refractory lattice bodies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com