Differential pressure power pressure booster

A supercharger and power technology, which is applied to machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of insufficient pressure and difficult exploitation of low-yield and low-pressure gas fields, so as to protect formation pressure, save production costs, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

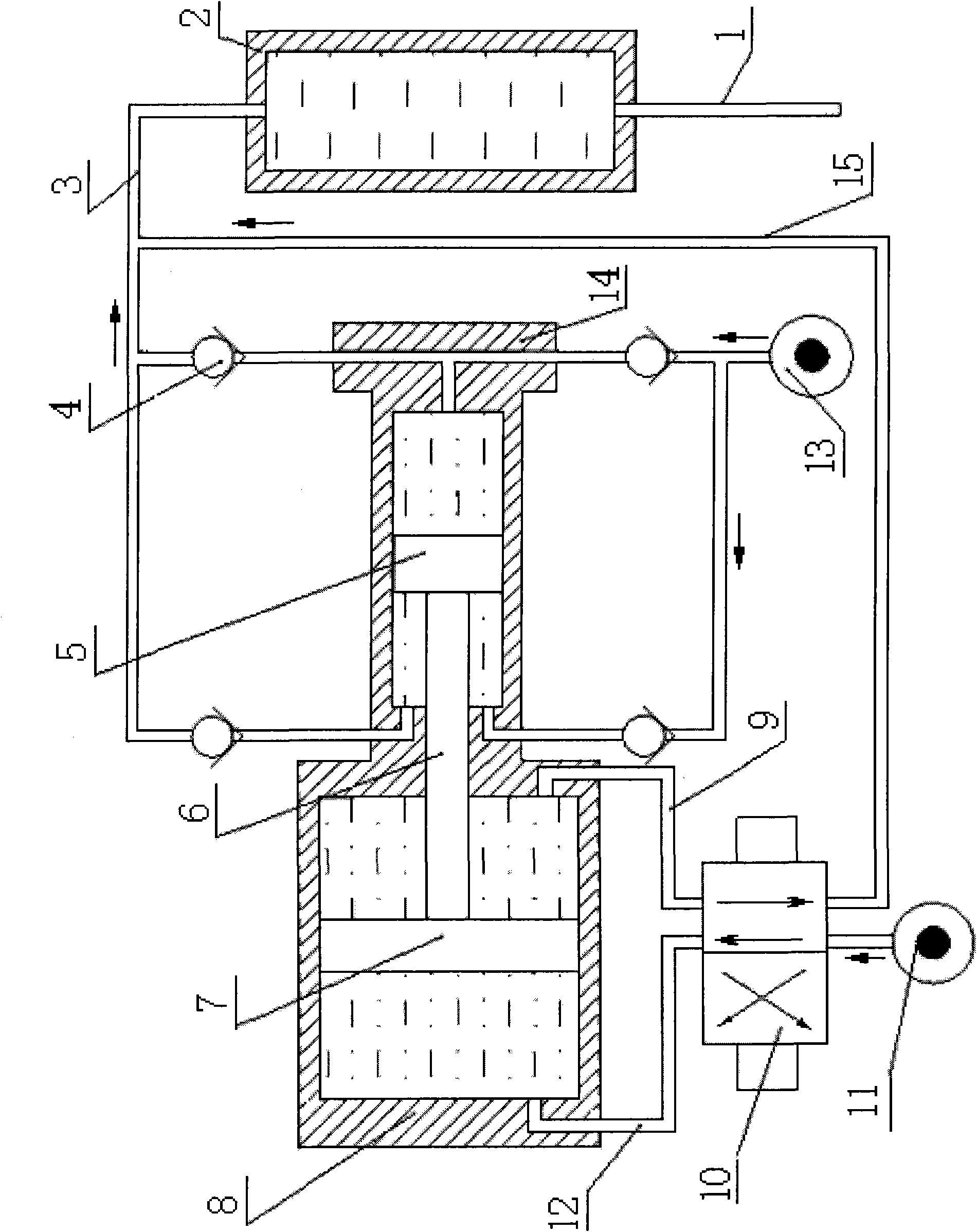

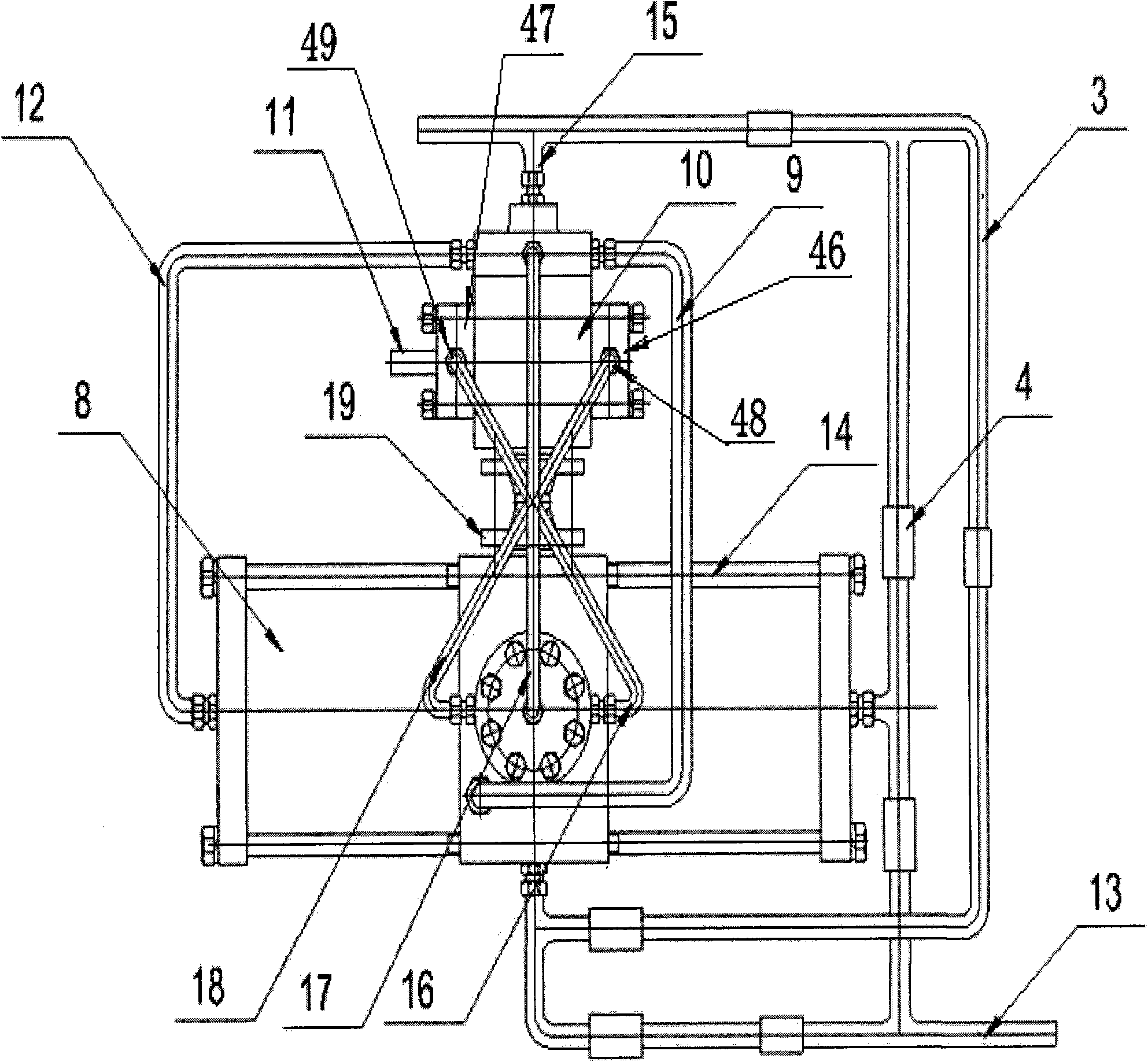

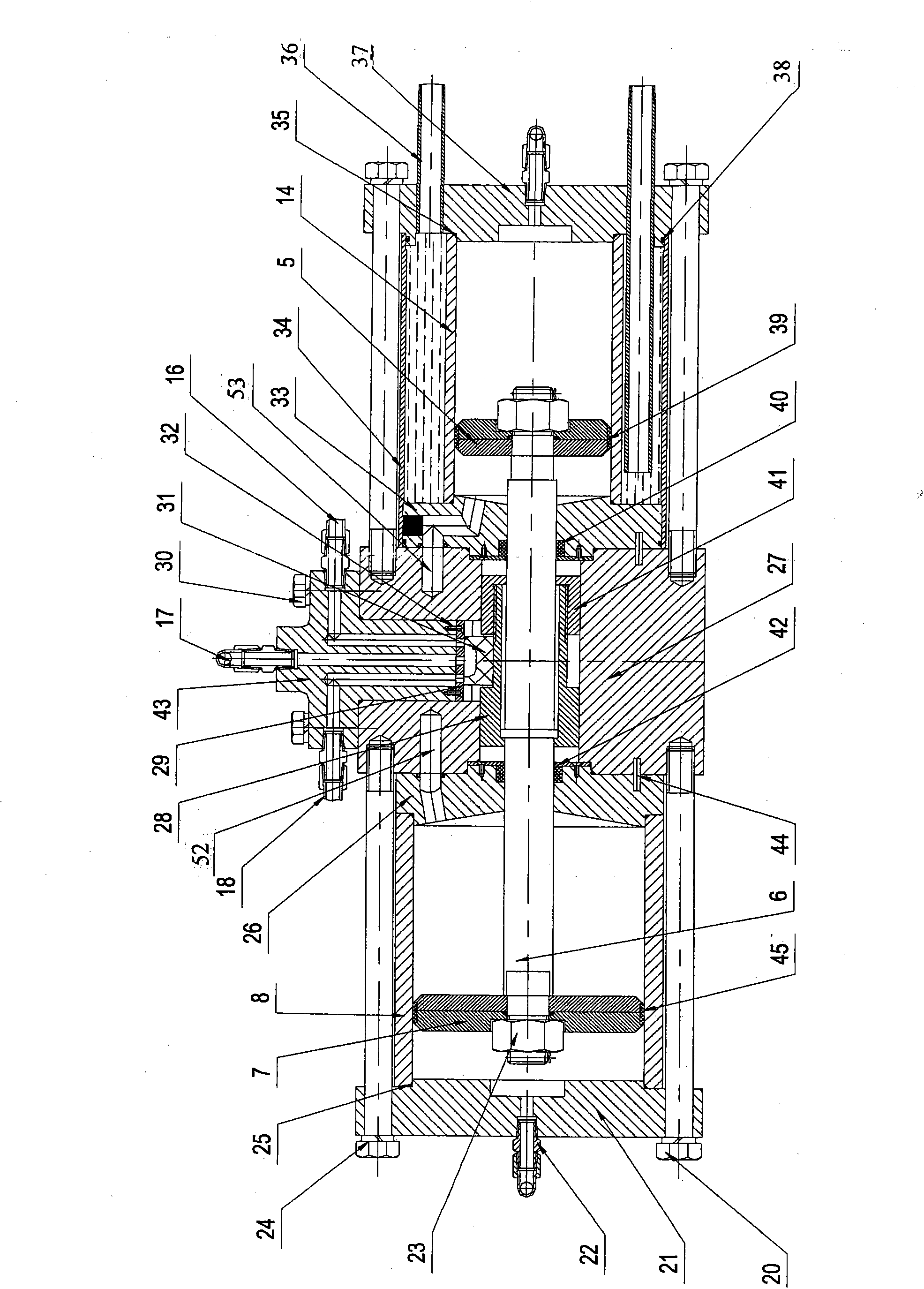

[0031] Embodiment 1: Taking a differential pressure power booster as an example, the present invention will be further described in detail.

[0032] refer to figure 1 . The differential pressure power booster is mainly composed of a compression cylinder discharge pipe 3, a one-way valve 4, a small piston 5, a piston rod 6, a large piston 7, a drive cylinder 8, a high-pressure right inlet and exhaust pipe 9, and a two-position four-way reversing Valve 10, high-pressure left intake and exhaust pipe 12, compression cylinder 14 and drive cylinder gas discharge pipe 15 form.

[0033] The driving cylinder 8 and the compression cylinder 14 are relatively connected together, the centerline of the driving cylinder 8 and the centerline of the compression cylinder 14 are the same straight line, and there is a piston rod 6 between the driving cylinder 8 and the compression cylinder 14. Both ends are respectively fixed with a large piston 7 and a small piston 5, the large piston 7 is in ...

Embodiment 2

[0044] Embodiment 2: see Figure 4 . Embodiment 2 is basically the same as Embodiment 1, the difference is: the two-position four-way reversing valve 10 is replaced with a two-position four-way solenoid valve 51, which is on the outer edge of the drive cylinder left cover 21 and the drive cylinder right A magnetic progressive switch 50 is respectively fixed on the outer edge of the cover 26. The magnetic progressive switch 50 is respectively connected to the two-position four-way solenoid valve 51, and the electric signal fed back by the magnetic progressive switch 50 controls the two-position four-way solenoid valve 51 to change direction. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com