Valve core of ball valve and processing method thereof

A valve core and ball valve technology, which is applied in the field of ball valve cores, can solve the problems of high consumption of raw materials, low structural strength, and large weight of components, etc., and achieve the effects of less raw material consumption, low manufacturing cost, and small weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

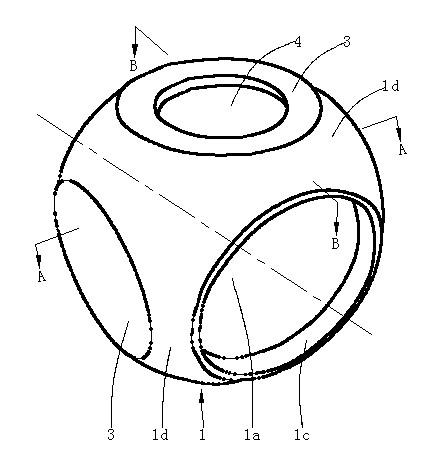

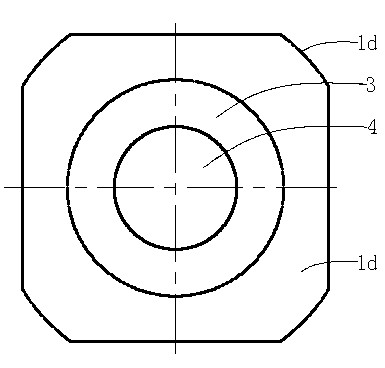

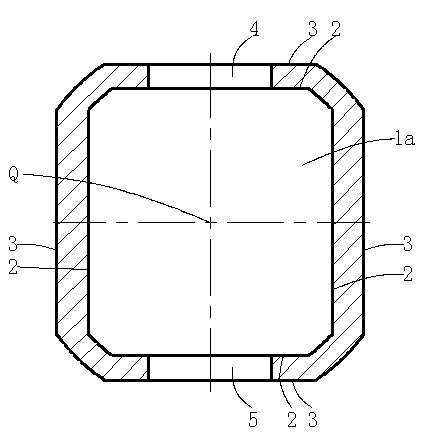

[0022] Such as Figure 1~4 As shown, a ball valve spool includes a sphere 1, the sphere 1 is a hollow structure, and the sphere 1 is provided with a liquid inlet 1b and a liquid outlet 1c communicating with the inner hole 1a, and the liquid inlet 1b and the liquid outlet The position of mouth 1c is opposite, and the size is the same. The structures of the sphere 1 and the liquid inlet and outlet are prior art, and will not be repeated here. During use, the liquid flows into the valve core through the liquid inlet 1b, passes through the inner hole 1a, and then flows out of the valve core through the liquid outlet 1c.

[0023] The outer surface of the sphere 1 is an arc surface 1d, and the structure of the arc surface 1d is in the prior art, and will not be repeated here. In order to strengthen the structural strength of the spool, four inner planes 2 parall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com