Vortex parallel flow countercurrent evaporator for automotive air conditioner

An automobile air conditioner and parallel flow technology, which is applied to evaporators/condensers, vehicle parts, tubular components, etc., can solve the problems of short refrigerant stroke, easy expansion, vibration deformation, etc., reduce processing difficulty, simplify production process, The effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

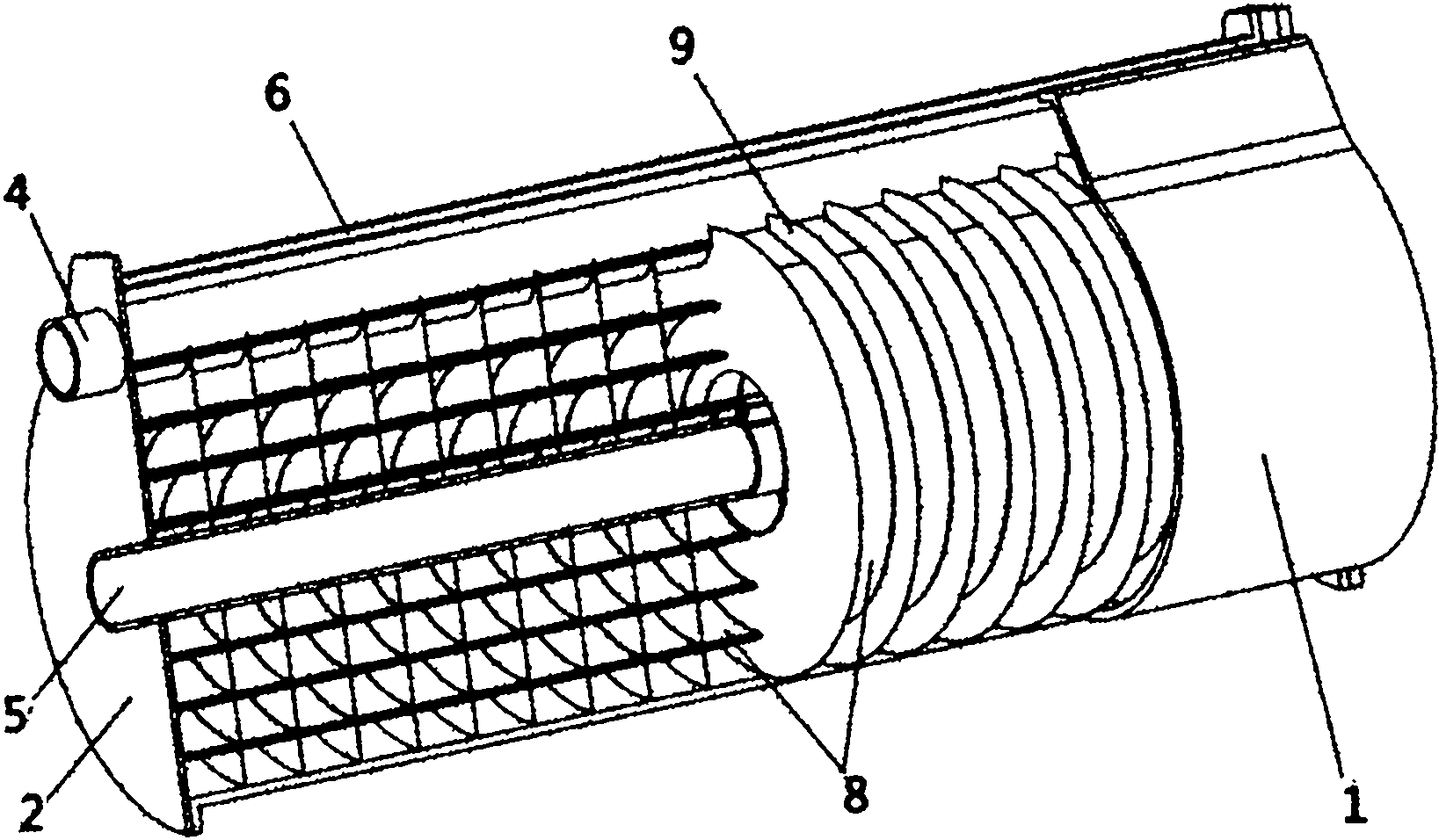

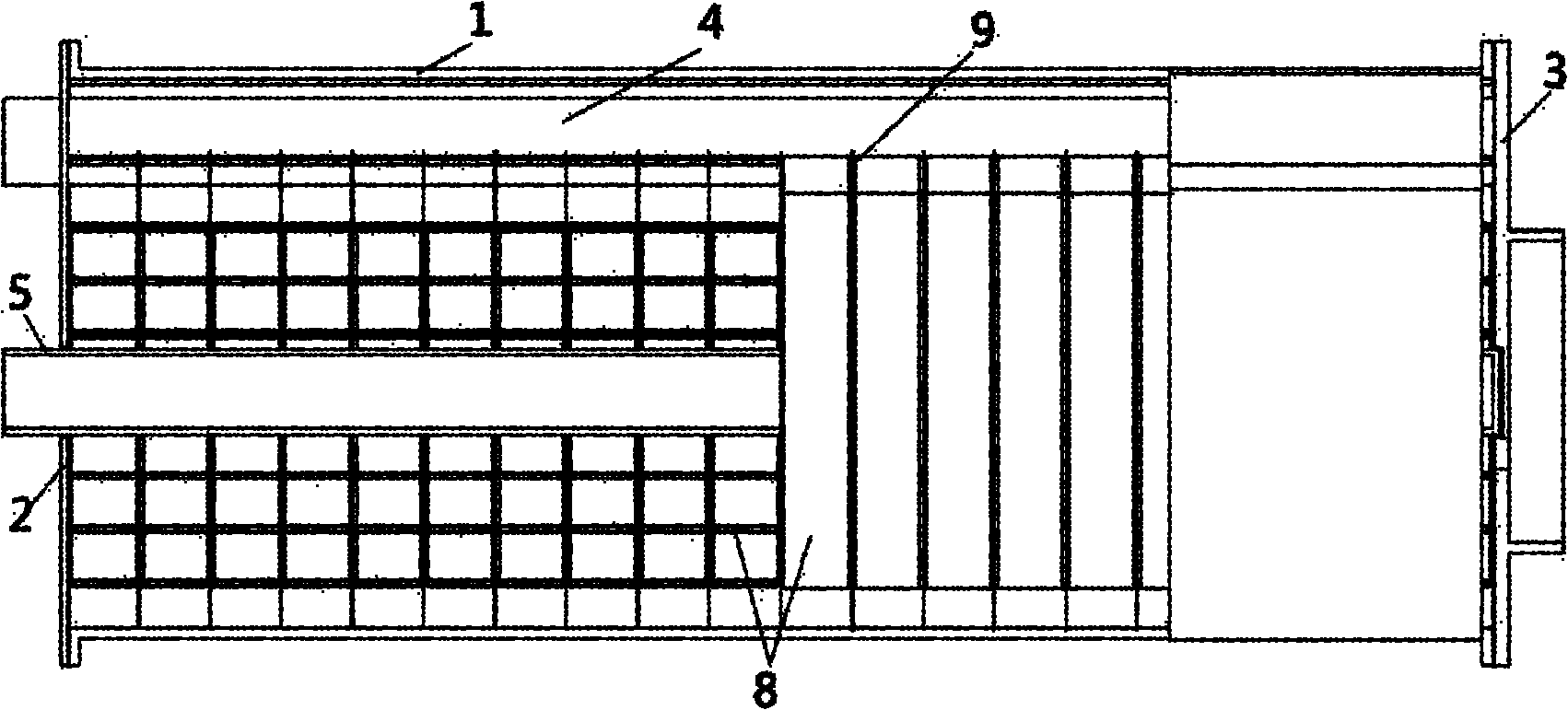

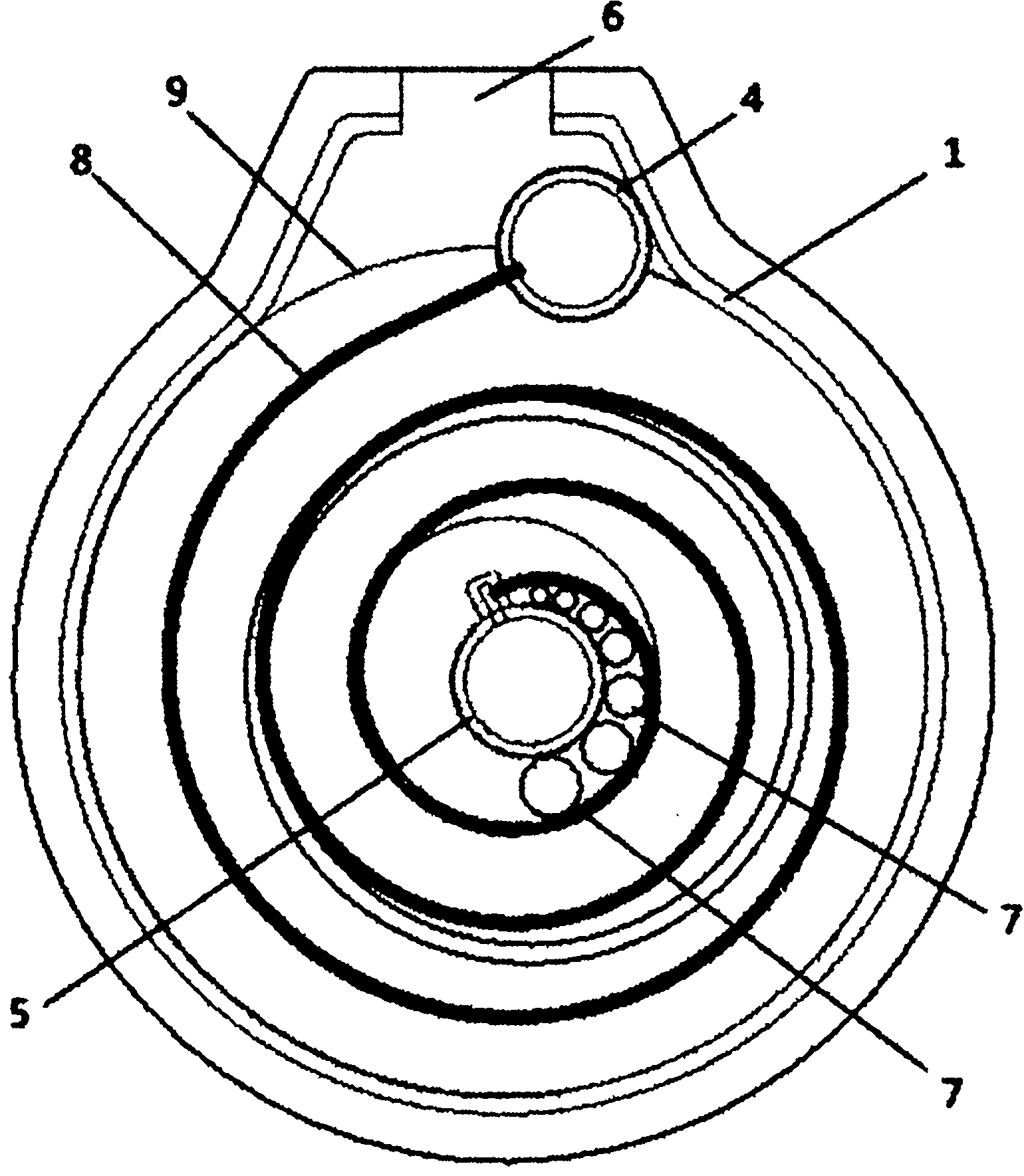

[0018] refer to Figure 1-5 A vortex parallel-flow counter-current evaporator for automobile air-conditioning, comprising a cylindrical shell 1, the cylindrical shell 1 is provided with a plurality of vortex-shaped flat tubes 8 arranged in parallel, and each vortex-shaped flat tube The tubes 8 are separated by fins 9, and the inner side of the cylindrical housing 1 is provided with slots connected with the fins 9; Adjacent vortex layers are sealed and connected to the fins 9 on both sides to form a refrigerant channel for heat exchange with the refrigerant. The inlet and outlet of each refrigerant channel are connected to each other, and the inlet and outlet of each refrigerant channel The outlets are respectively connected to each other, and the refrigerant in the refrigerant passage and the brine in the brine passage flow in reverse directions. The outermost end of the scroll-type flat tube 8 is arranged with a first header 4 communicating with the outlet of each refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com