Device for automatically adjusting flux of refrigeration working medium

A technology of refrigeration working fluid and automatic adjustment, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of complicated equipment and manufacturing, and cannot provide general expansion technology for mixed working fluids, so as to improve the coefficient of performance and load, Facilitate development and application, and improve the effect of COP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

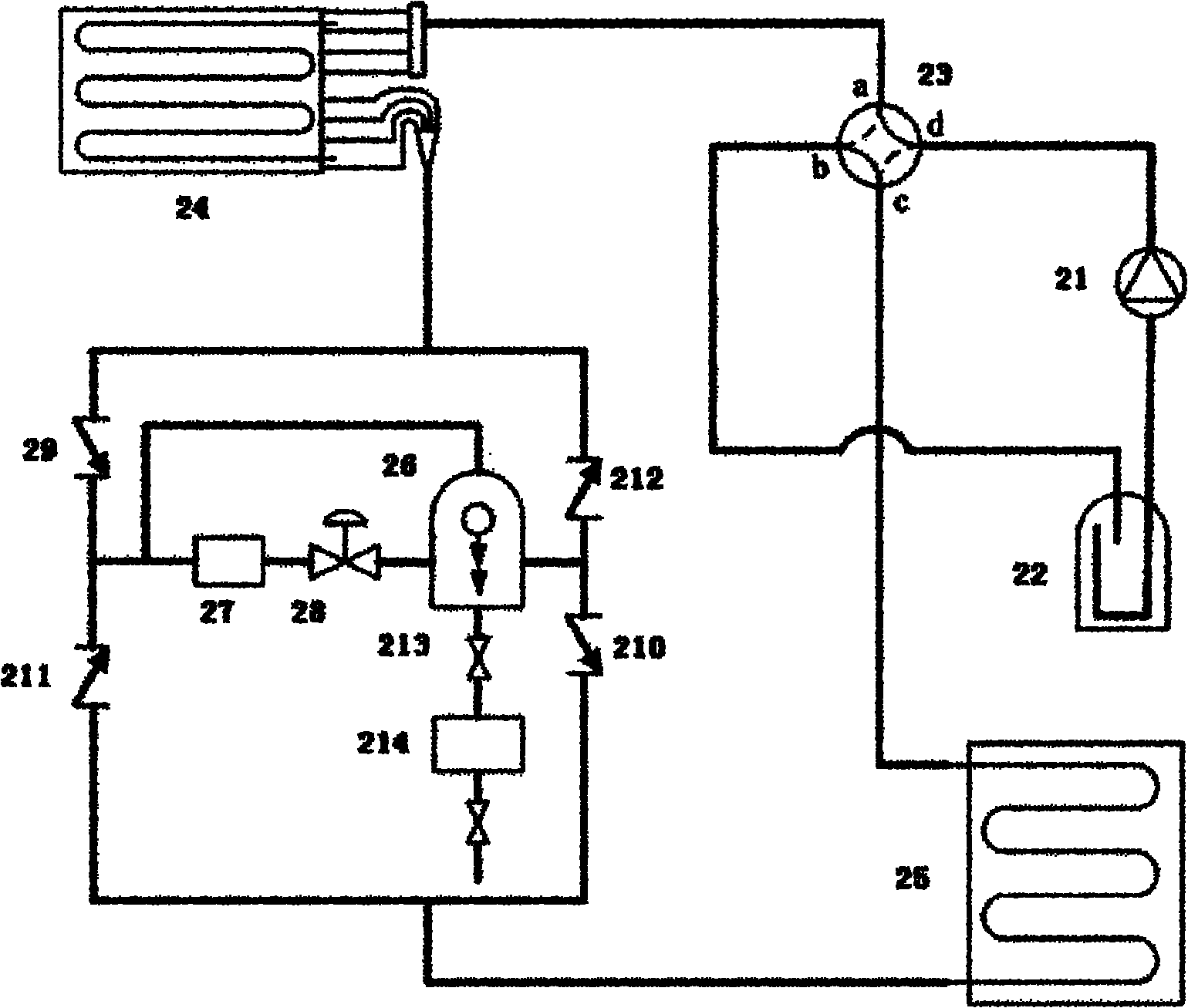

[0022] Such as figure 1 As shown, when the device of the present invention is used for a unit with switchable cooling and heating modes, when the unit is in the cooling mode, the external unit 24 is a condenser, and the internal unit 25 is an evaporator, and the high-temperature and high-pressure refrigeration unit coming out of the compressor 21 The substance enters the four-way valve 23, enters from terminal d, flows out from terminal a, enters the external machine 24, and is condensed into a liquid state. Under the guidance of the one-way valve 29, the liquid working medium enters the float expansion valve 26 through the dry filter 27 and the solenoid valve 28, and the ball valve 213 can be opened as required to store the liquid working medium in the liquid reservoir 214; Next, the liquid working medium flowing from the external machine 24 will be directly injected into the working chamber of the float expansion valve 26. Due to the special design of the valve, the valve bo...

Embodiment 2

[0029] like figure 1 As shown, when the device of the present invention is used in a unit with switchable refrigeration and heating modes, when the unit is in the heating mode, the external unit 24 is an evaporator, the internal unit 25 is a condenser, and the high-temperature and high-pressure refrigeration from the compressor 21 The working fluid enters the four-way valve 23, enters from terminal d, flows out from terminal c, enters the internal unit 25, and is condensed into a liquid state. Under the guidance of the one-way valve 211, the liquid working medium enters the float expansion valve 26 through the dry filter 27 and the solenoid valve 28, and the ball valve 213 can be opened as required to store the liquid working medium in the liquid reservoir 214; Next, the liquid working medium flowing from the internal unit 25 will be directly injected into the working chamber of the float expansion valve 26. Due to the special design of the valve, the valve body is only affect...

Embodiment 3

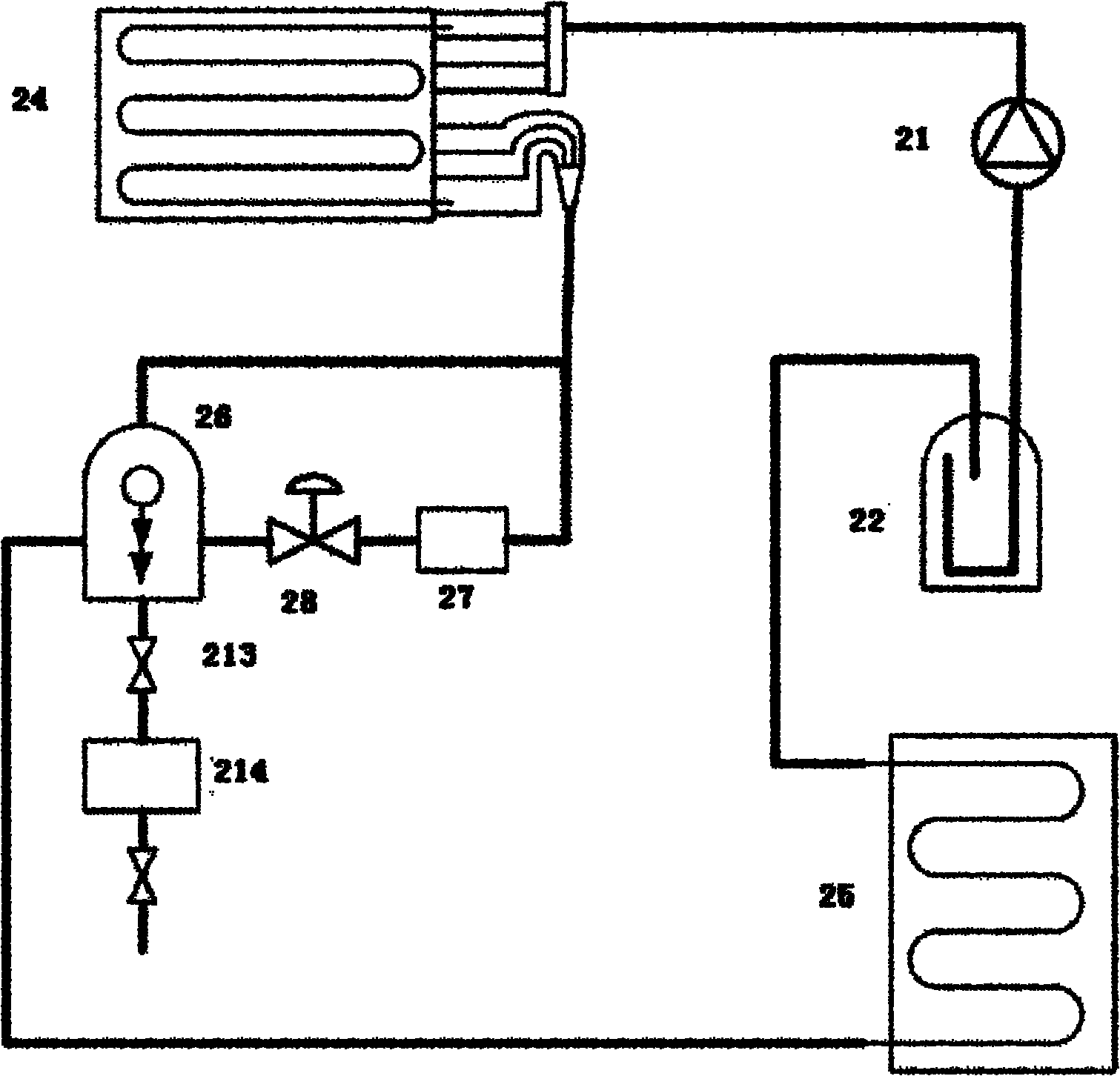

[0032] like figure 2 As shown, when the device of the present invention is used in a single-function refrigeration unit, the external machine 24 is a condenser, and the internal machine 25 is an evaporator, and the high-temperature and high-pressure refrigerant coming out of the compressor 21 enters the external machine 24 and is condensed into a liquid working medium . The liquid working medium enters the float expansion valve 26 through the dry filter 27 and the electromagnetic valve 28, and the ball valve 213 can be opened as required to store the liquid working medium in the liquid reservoir 214; The liquid working medium will be directly injected into the working chamber of the float expansion valve 26. Due to the special design of the valve, the valve body is only affected by the buoyancy of the float ball and is not affected by the pressure difference force of the expansion valve. The movement of the valve body is smooth and free. The working medium can be expanded ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com