High-temperature-resistant corundum mullite roller way plate in kiln cavity of totally-enclosed kiln

A fully airtight, high-temperature-resistant technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve problems affecting the use of kilns, arch kilns, etc., and achieve the effect of reducing investment in supporting equipment, investment and loss.

Inactive Publication Date: 2012-07-04

湖南航天有限责任公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the phenomenon that the existing kiln roller table is prone to arch kiln, which affects the use of the kiln, the present invention aims to provide a high temperature resistant corundum mullite roller table in the cavity of a fully enclosed kiln , the roller table can effectively solve the problem of the roller table arch kiln, and has a simple structure, low manufacturing cost, safety and reliability, and a wide range of sintering temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

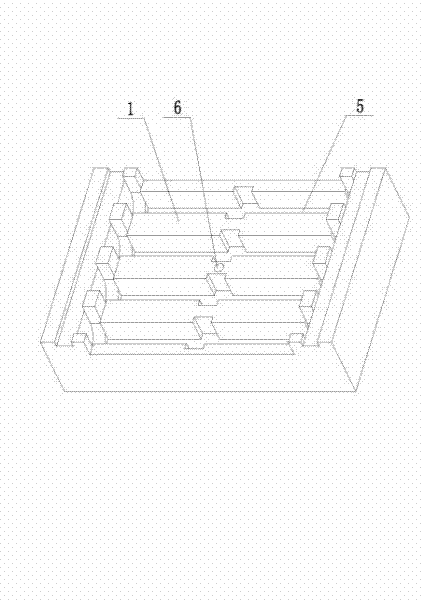

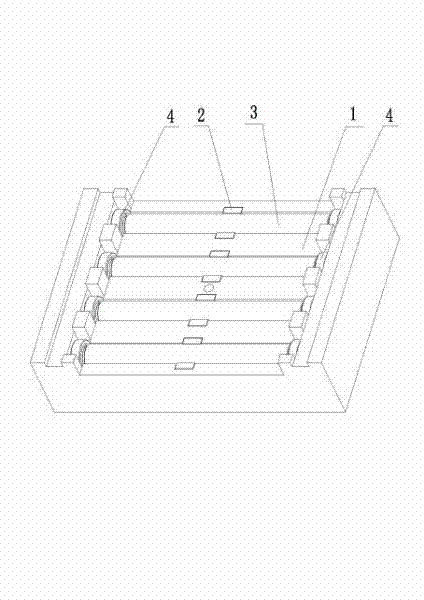

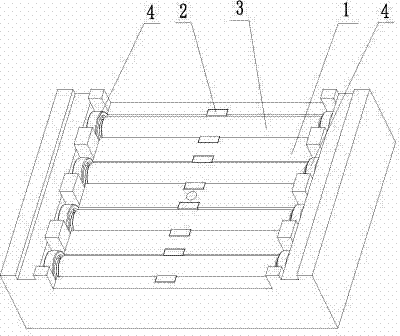

The invention discloses a high-temperature-resistant corundum mullite roller way plate in the kiln cavity of a totally-enclosed kiln and aims to solve the problem of high probability of kiln arching of the conventional kiln roller way plate. The high-temperature-resistant corundum mullite roller way plate comprises a plurality of corundum mullite bricks which are taken as bottom plates of a roller way kiln, wherein each corundum mullite brick is provided with a plurality of roller grooves; the two ends of each roller groove are provided with corundum bearings; a corundum roller is arranged above each roller groove; and the two ends of the corundum roller are arranged in the corundum bearings respectively. The roller way plate has a small rolling friction coefficient, a simple structure, low manufacturing cost and wide sintering temperature range, can effectively reduce or avoid kiln arching accidents caused by large friction pressure of the kiln or the falling of a hot part into the kiln cavity and is safe and reliable.

Description

technical field [0001] The invention relates to a high-temperature-resistant corundum-mullite roller table in a fully-sealed kiln chamber. Background technique [0002] Most of the existing fully enclosed kiln roller table adopts corundum roller table. Due to the high friction coefficient of corundum, it will cause difficulty in advancing the material during the feeding process of the kiln, and it will be different from the previous ones. The phenomenon of arch kiln occurs when the material phase collides, which affects the production of materials and the use of kiln. At the same time, due to the small bending resistance of corundum, when the mass of the material is large, the corundum roller table will break, which will cause the overall destruction of the kiln cavity. At the same time, when this roller table method is adopted, the friction coefficient of many kilns becomes larger due to the falling of slag, and the sliding coefficient becomes smaller. Difficult to refle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27B9/30

Inventor 张刚彭锦波曹二斌周飞孙友元万绍平戴传波

Owner 湖南航天有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com