Automatic calibration method for inclinometer

An automatic calibration and inclinometer technology, which is applied to instruments, measuring devices, optical devices, etc., can solve problems such as difficult to ensure measurement accuracy and reliability, low detection accuracy, and difficult positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

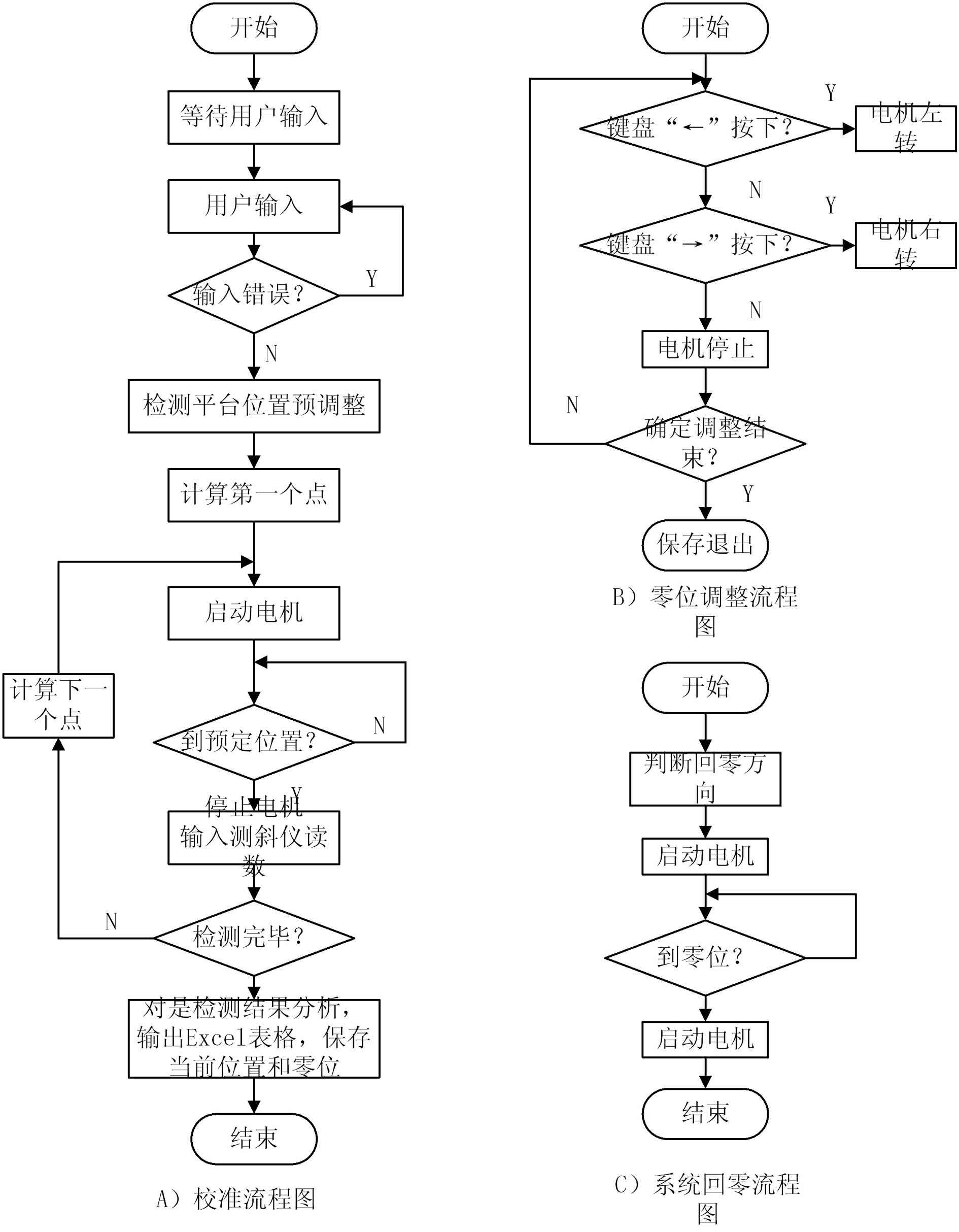

[0024] Below in conjunction with accompanying drawing and example the patent of the present invention is further described.

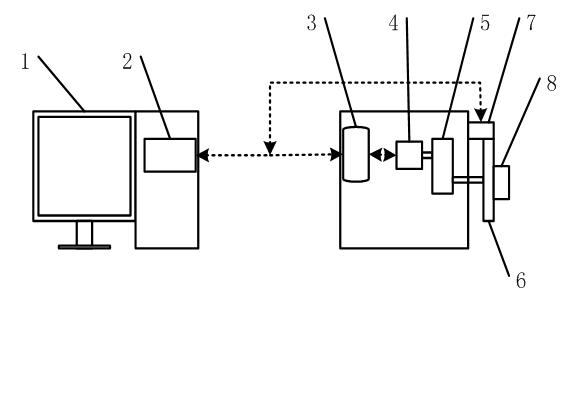

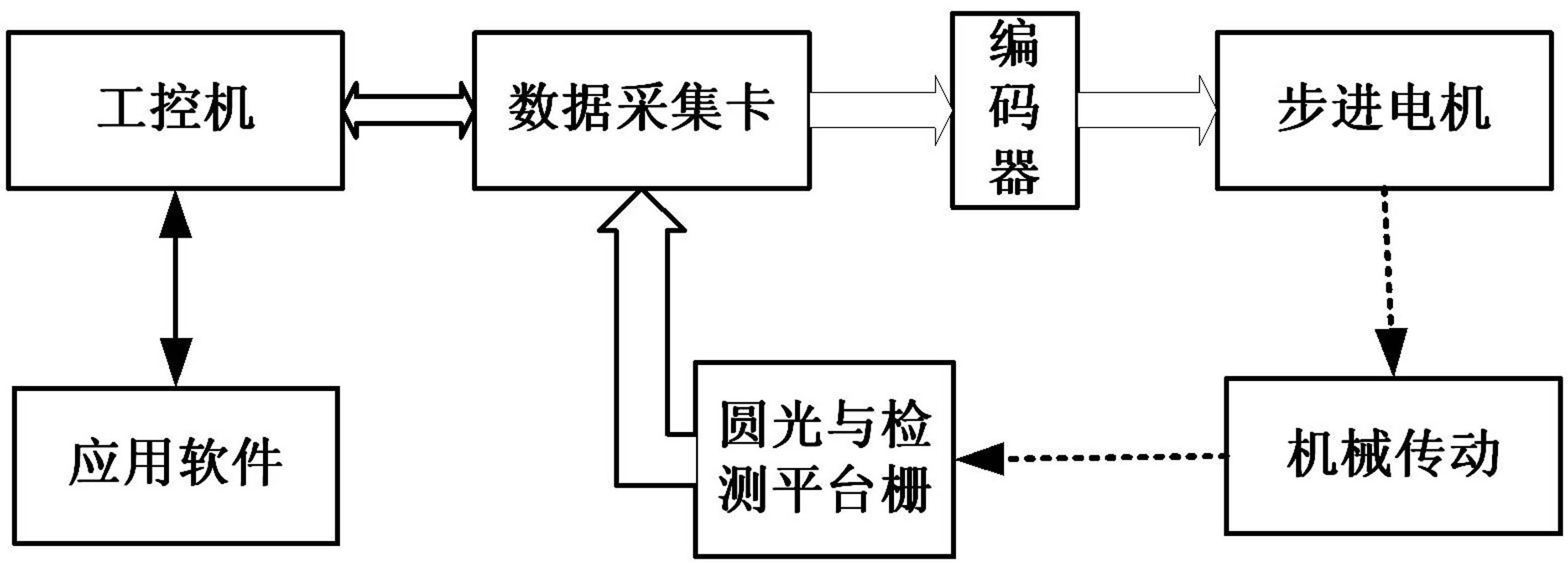

[0025] refer to figure 1 and figure 2 The automatic calibration device for the inclinometer shown includes 1. Industrial computer and software, 2. Data acquisition card, 3. Stepper motor controller, 4. Stepper motor, 5. High-precision mechanical transmission mechanism, 6. Circle Grating, 7. circular grating reading head, 8. detection platform, industrial computer 1 is connected with data acquisition card 2, data acquisition card 2 is connected with circular grating sensor, motor controller 3, stepper motor 4 is connected with mechanical transmission mechanism 5, The mechanical transmission mechanism 5 is connected with the detection platform 8 , and the circular grating sensor is installed on the shaft of the detection platform 8 .

[0026] First, read in a series of set values through the industrial computer software, and calculate the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com