Shunting type coal gas flow measurement device and measurement method thereof

A technology for gas flow and measuring device, which is applied in the direction of measuring device, measuring capacity, liquid/fluid solid measurement, etc., can solve the problems of lack of devices and methods for removing impurities, reducing the accuracy of total flow calculation, and measuring failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

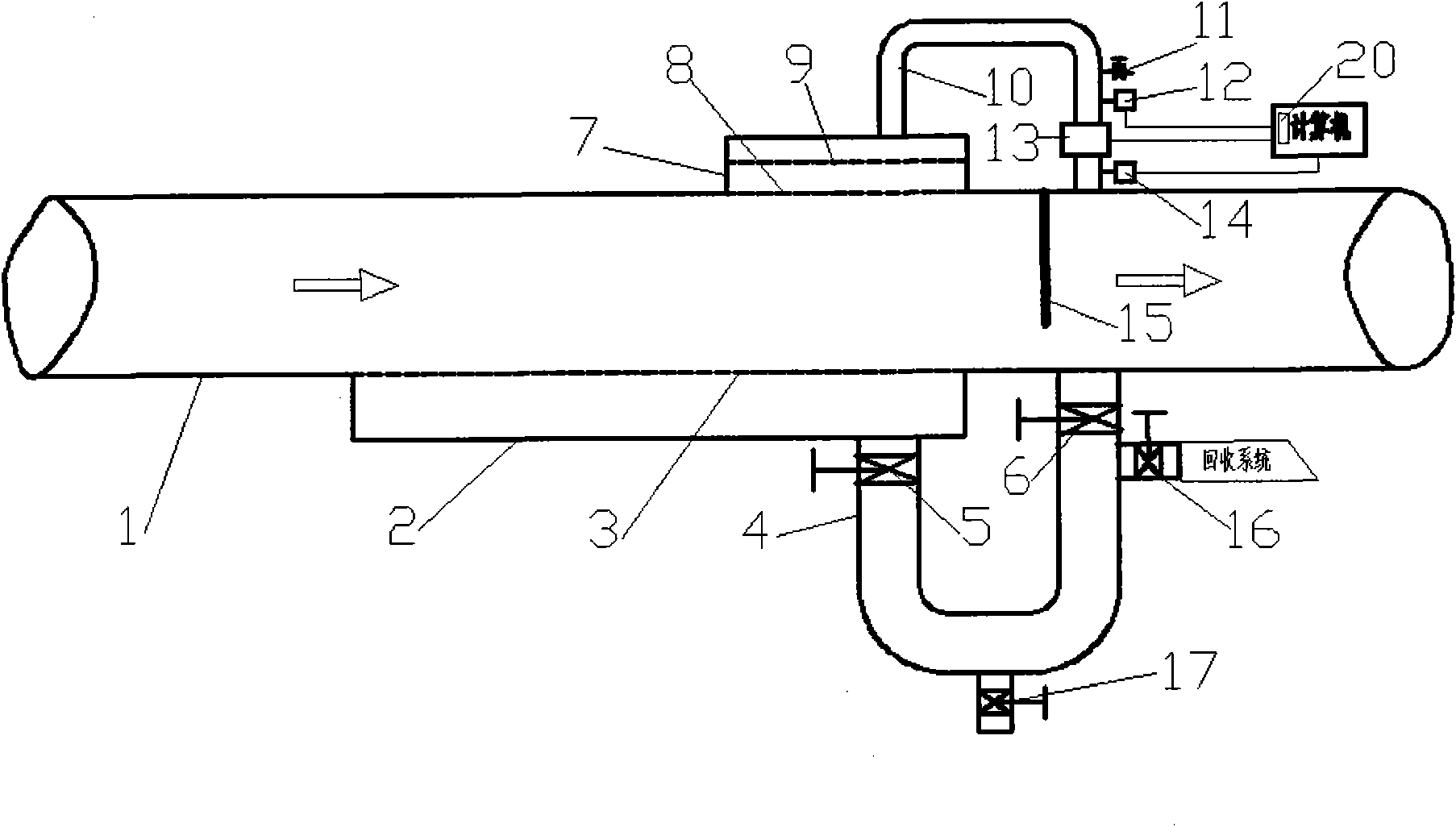

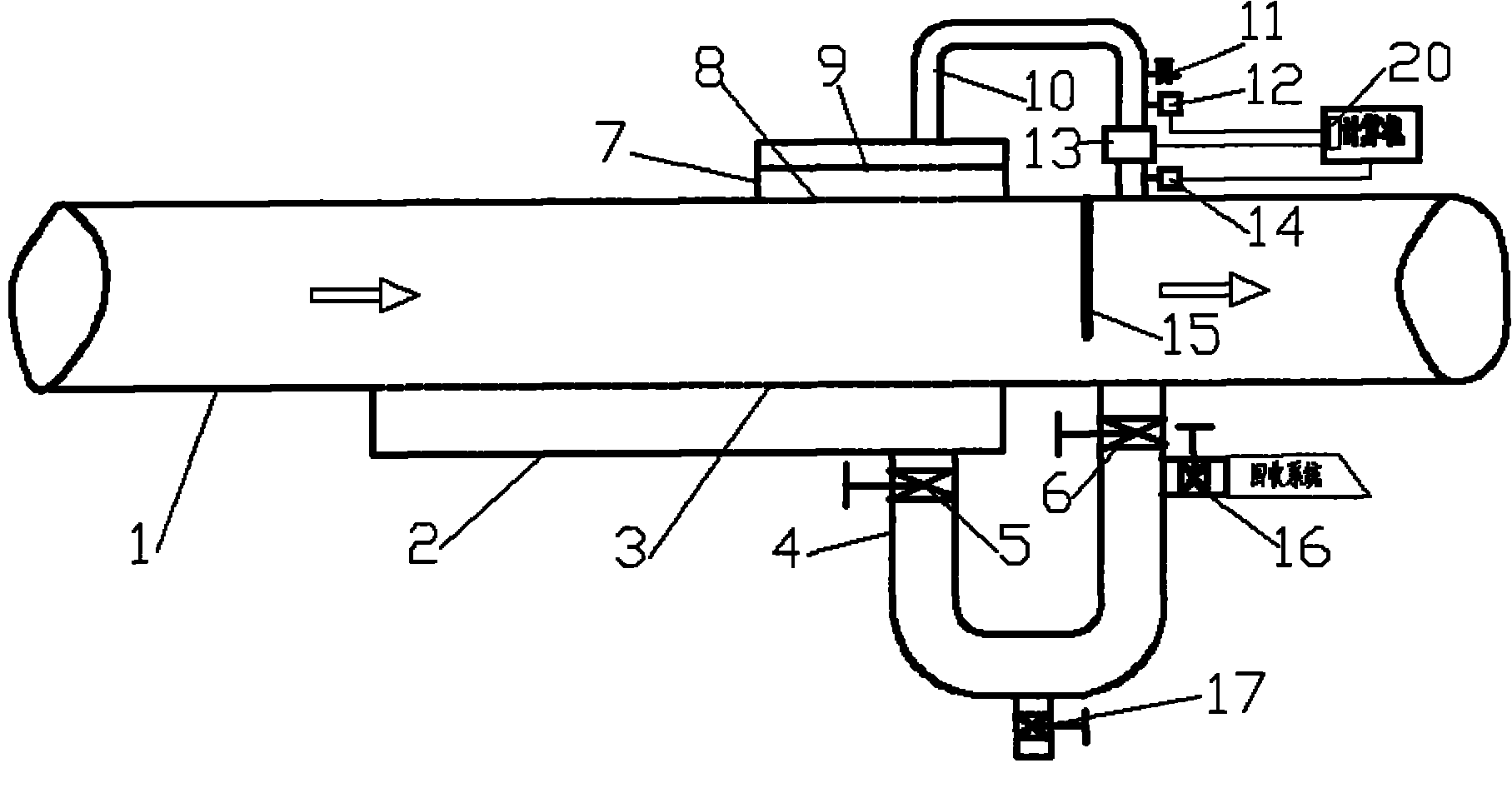

[0016] The present invention will be described in more detail below in conjunction with the drawings.

[0017] As shown in the figure, the split gas flow measuring device includes a gas flow meter 13, and also includes a horizontal pipe 1. The top side and bottom side of the horizontal pipe 1 are respectively provided with a gas collecting tank 7 and a liquid collecting tank 2, and the collecting The bottom of the air box 7 and the top of the horizontal pipe 1 are connected through the upper porous wall 8, and the top of the collecting tank 2 and the bottom of the horizontal pipe 1 are connected through the lower porous wall 3. The top side and the bottom side of the upper arch-shaped inverted U-shaped tube 10 and the lower inverted arch-shaped U-shaped tube 4 are respectively provided. One end of the upper arch-shaped inverted U-shaped tube 10 is in communication with the gas collecting box 7, and the other One end is connected to the top of the horizontal pipe 1, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com