High-speed train wheel track contact stress test bench

A contact stress, high-speed train technology, applied in the direction of railway vehicle testing, force measurement, measuring devices, etc., can solve problems such as unsatisfactory, inconsistent with the actual working state of the wheelset, etc., to achieve accurate loading, ensure safety and comfort, Monitor results for precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

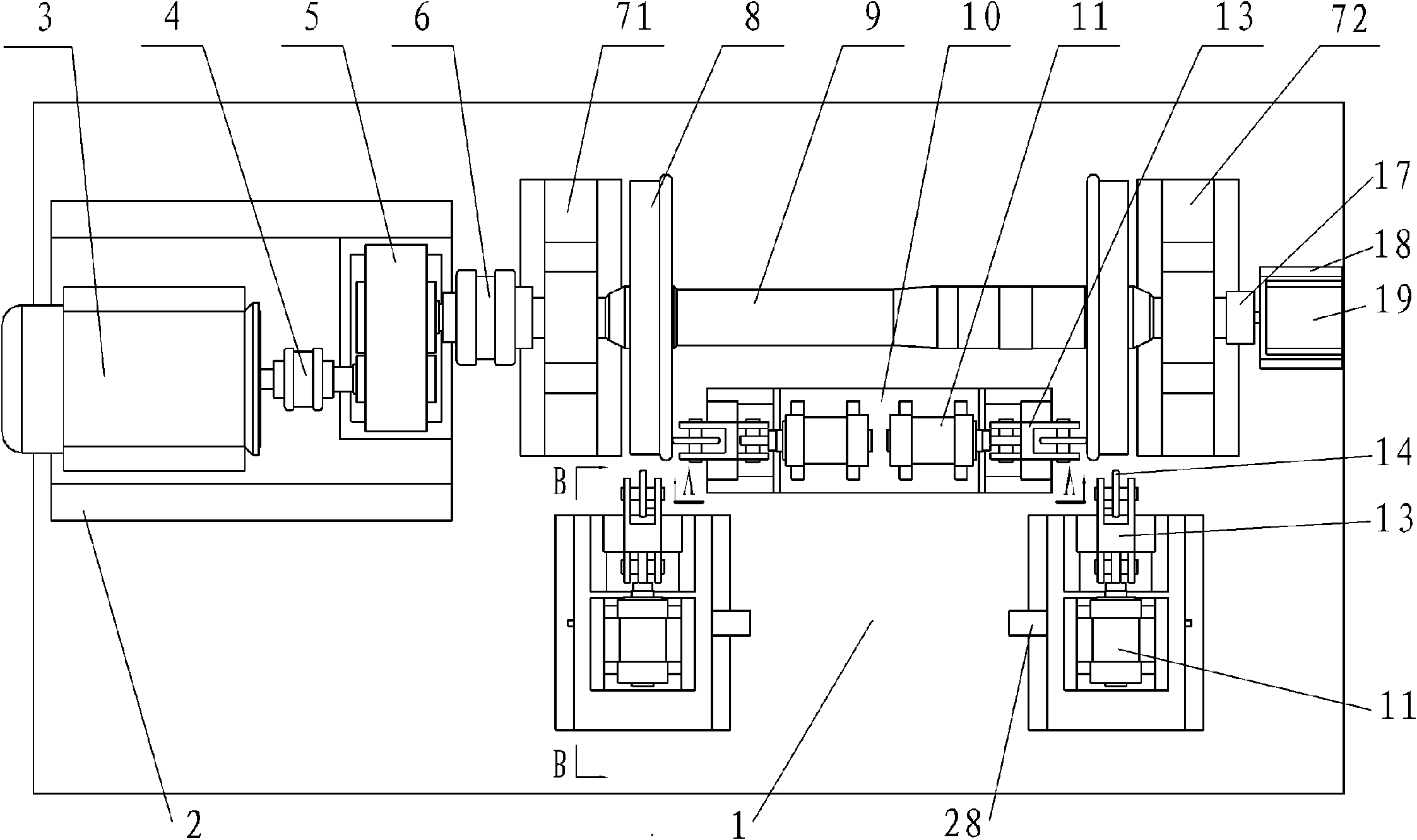

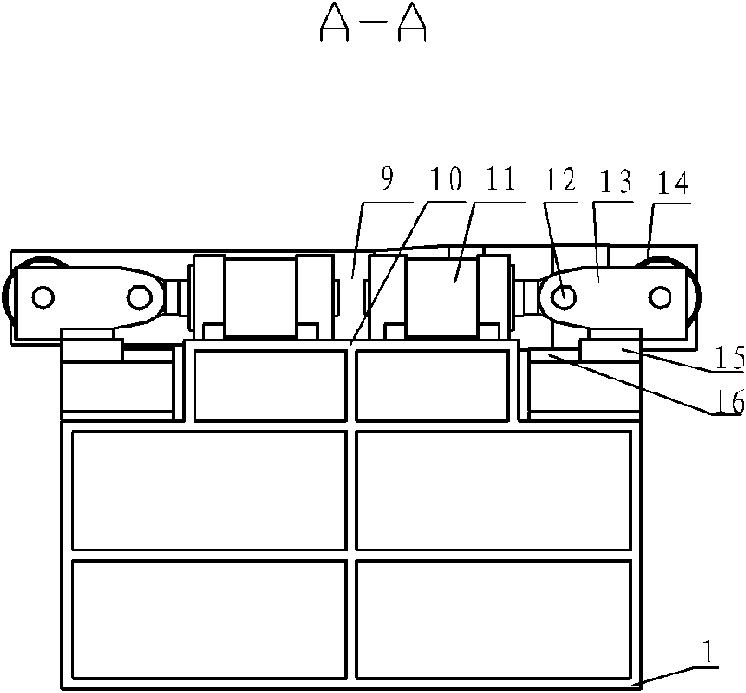

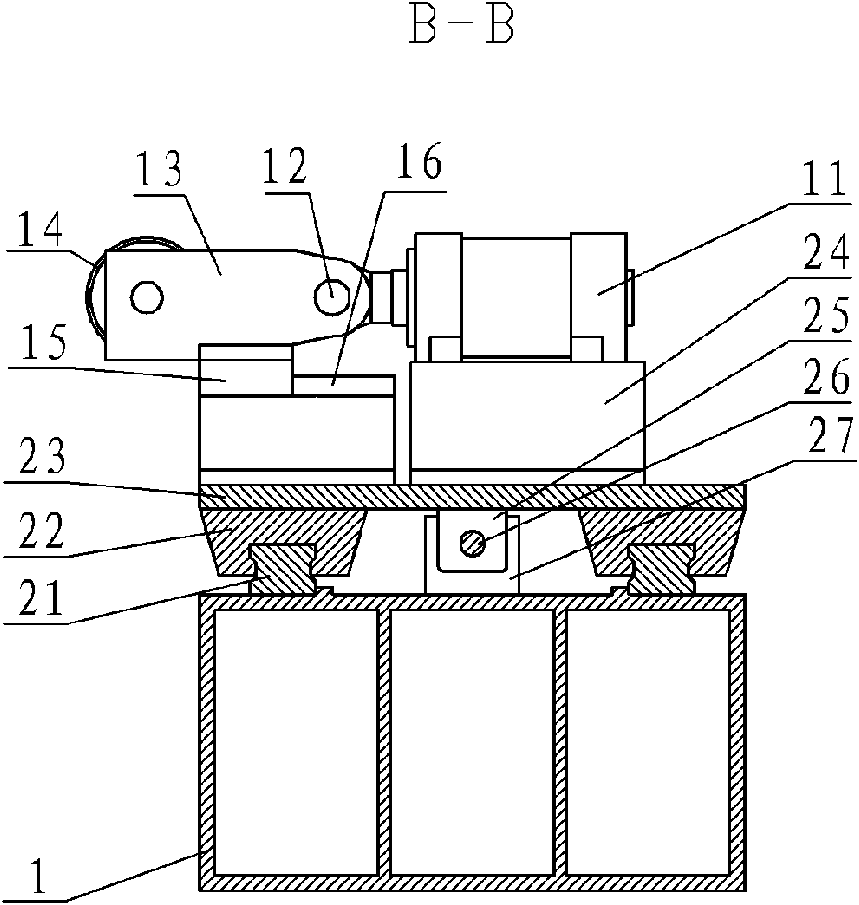

[0024] Figure 1-3 It is shown that a specific embodiment of the present invention is a high-speed train wheel-rail contact stress test bench, including a bench 1, an axial and radial hydraulic loading system, a strain detection device, a wireless transmission device and a data processing device.

[0025] The stand 1 is provided with left and right wheel frames 71, 72 for installing the wheel pair 8, and the wheel shaft 9 of the wheel pair 8 is mounted on the left and right wheel frames 71, 72 through bearings.

[0026] The left end of the wheel shaft 9 is also connected with the output shaft of the reducer 5 through the dynamic load clutch 6, the input shaft of the reducer 5 is connected with the drive motor 3 shafts through the coupling 4, and the right end of the wheel shaft 9 is connected with the static load servo through the static load clutch 17. The output shaft of the motor 19 is connected, and the static load servo motor 19 is installed on the stand 1 through the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com