Method for analyzing beating performance of wood sulfate pulp

A kraft pulp and beating performance technology, which is applied in the field of pulp beating performance analysis, can solve the problems of cumbersome analysis and measurement procedures, and achieve the effects of easy popularization and application, improved comprehensive utilization value, and simple and fast procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

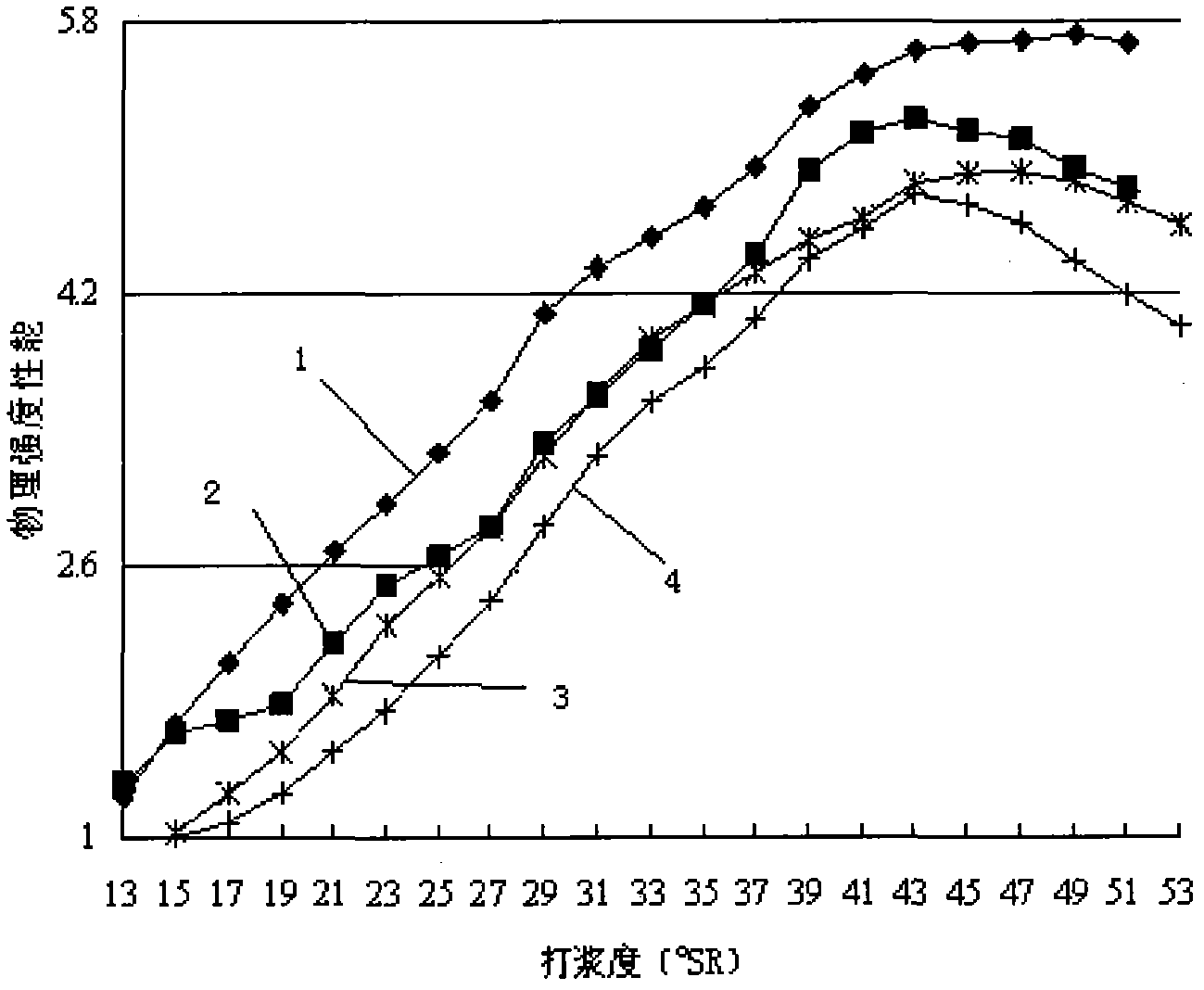

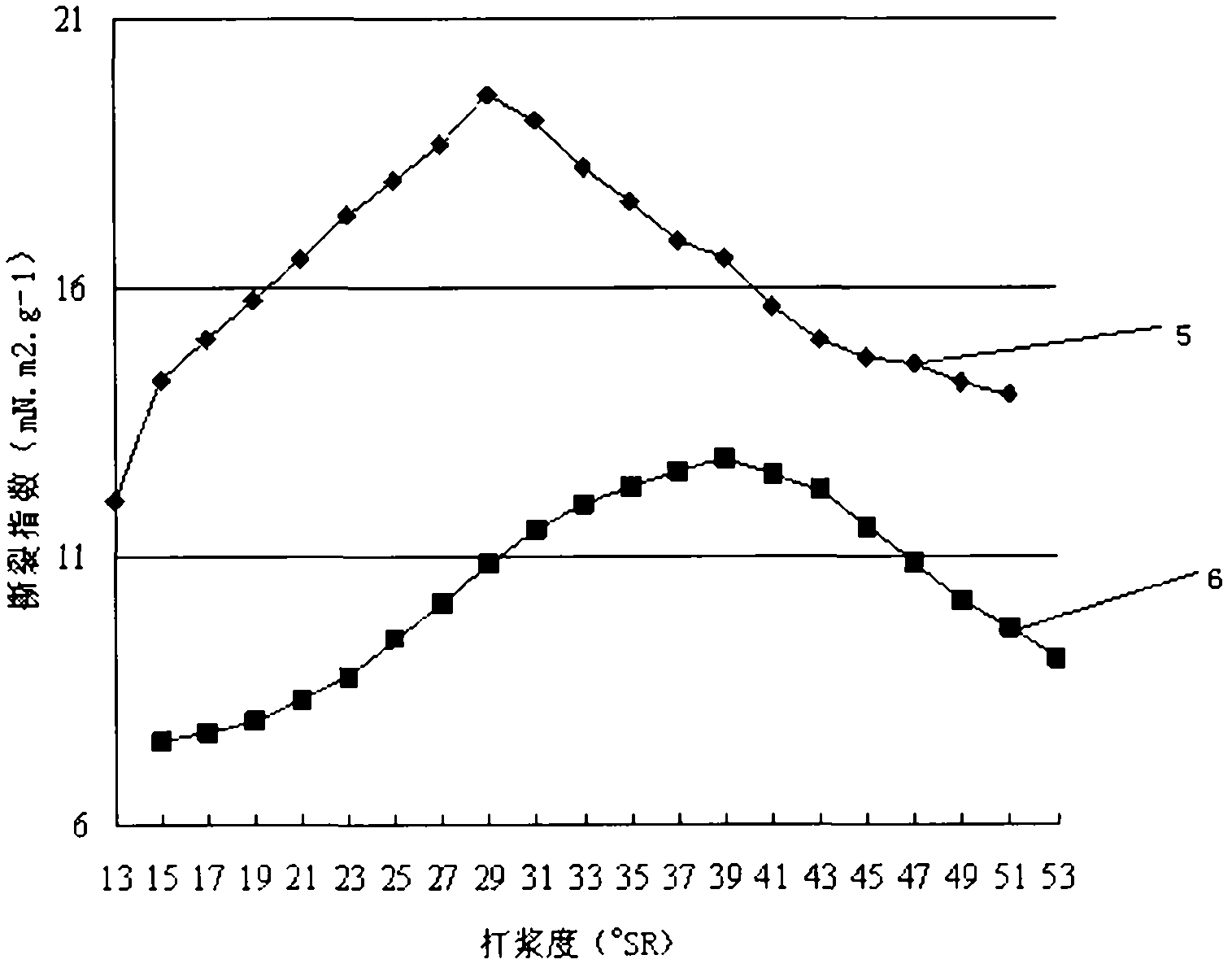

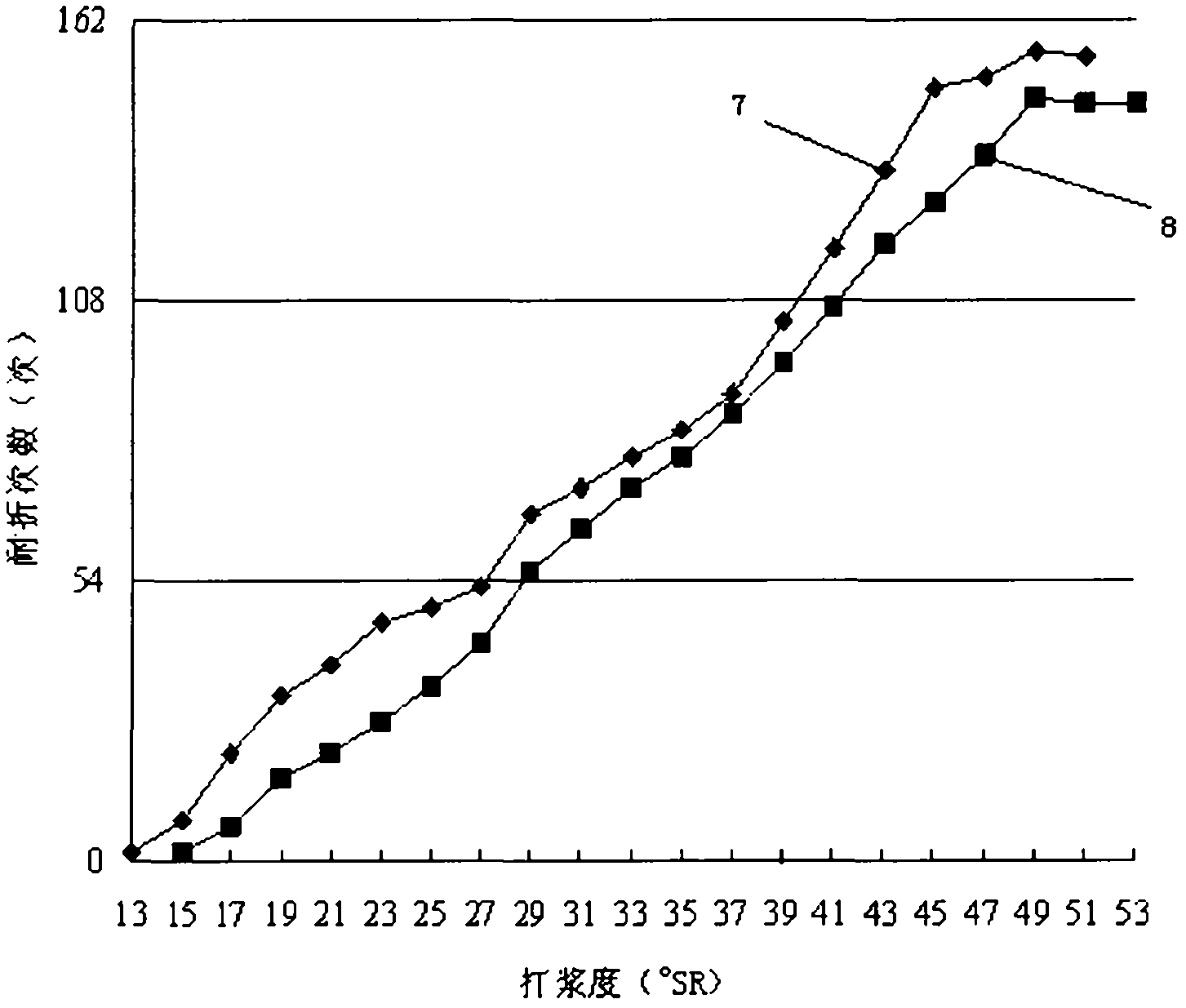

[0050] Adopt conventional analysis method to analyze the bleached kraft pulp of Acacia lobosa hardwood through beating, first use the Schopper-Riegler beating degree meter to measure the degree of beating as 36 ° SR, and then measure the fiber characteristic parameters with a microscope as the number average fiber length is 0.608mm, and the width is 0.608 mm. The water retention value is 20.5 μm, and the water retention value is measured by a centrifuge to be 181%, and then the sheet is copied on a paper sheet machine, and the physical strength index of the pulp is measured by a paper physical strength tester. The fracture length is 4.14km, and the tear index is 12.37mN m 2 g -1 , burst resistance index 3.74kPa m 2 g -1 , The folding number is 78. The above analysis tests can confirm that the beating process is more suitable, the physical strength index of the pulp is better, and the drainage of the pulp is also better.

[0051] The beating performance of the bleached kraf...

Embodiment 2

[0053] Adopt conventional analysis method to analyze the softwood bleached kraft commercial pulp (Lion brand) through beating, first use the Schopper-Riegler type beating degree meter to measure the beating degree to be 40 ° SR, then record the fiber characteristic parameter as the number-average fiber length of 1.179mm, the width is 25.5μm, and the water retention value is measured by a centrifuge to be 142%, and then the sheets are copied on a paper sheet machine, and the physical strength index of the pulp is measured by a paper physical strength tester. The fracture length is 5.41km, and the tear Crack index 16.51mN·m 2 g -1 , burst resistance index 5.09kPa·m 2 g -1 , The number of folding endurance is 112. The above analysis tests can confirm that the beating process is more suitable, the physical strength index of the pulp is better, and the drainage performance of the pulp is also better.

[0054] The beating performance of softwood bleached kraft pulp (Lion brand) ...

Embodiment 3

[0056] The fast-growing poplar bleached kraft pulp (hardwood) made by the laboratory was analyzed by conventional analysis methods. The beating degree was first measured by the Schopper-Riegler type beating degree meter to be 42°SR, and then the fiber characteristic parameters were measured by the microscope. The average fiber length is 0.572mm, the width is 22.5μm, and then the water retention value is measured by a centrifuge to be 192%, and then the sheet is made on a paper sheet machine, and the physical strength index of the pulp is measured by a paper physical strength tester. 7.09km, tear index 10.98mN m 2 g -1 , burst index 3.05kPa·m 2 g -1 , The number of folding endurance is 109. The above analysis tests can confirm that the beating process is more suitable, the physical strength index of the pulp is better, and the drainage of the pulp is also better.

[0057]The beating performance of the fast-growing poplar bleached kraft pulp (hardwood) after beating is measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com