Method for optimizing process operation of catalytic hydrogenation reaction of acetylene in industrial device

A technology for reaction process and optimized operation, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as model parameters that cannot be directly applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

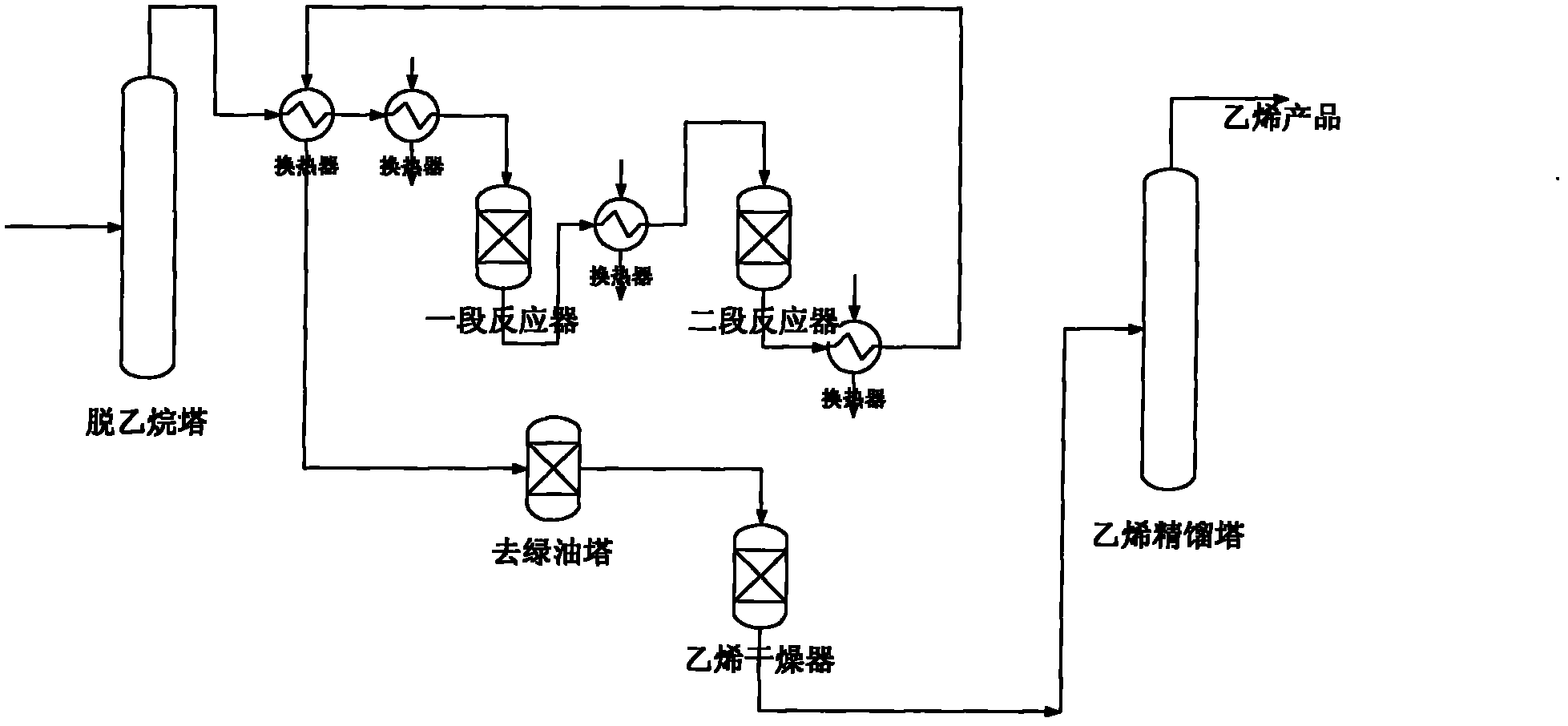

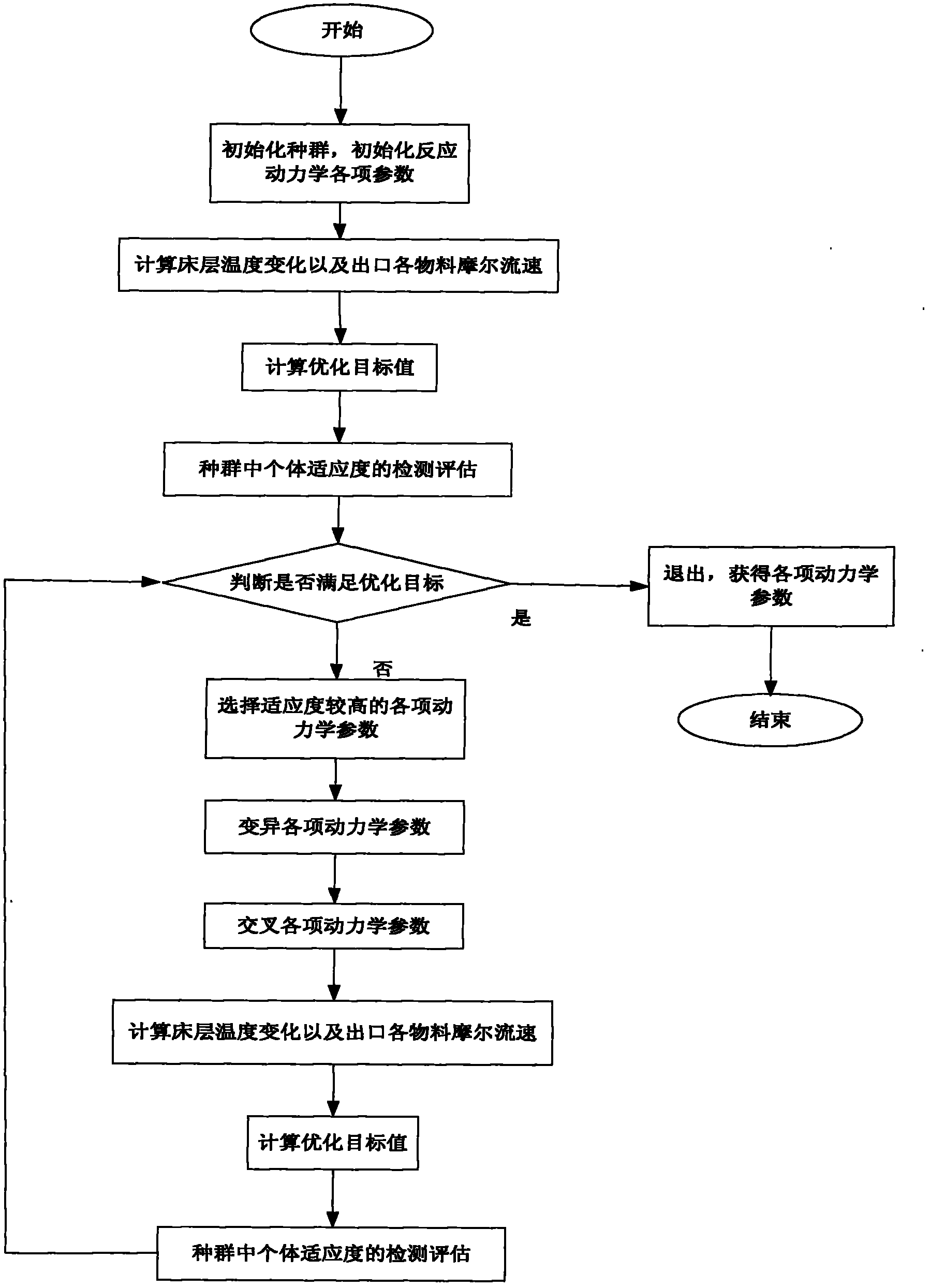

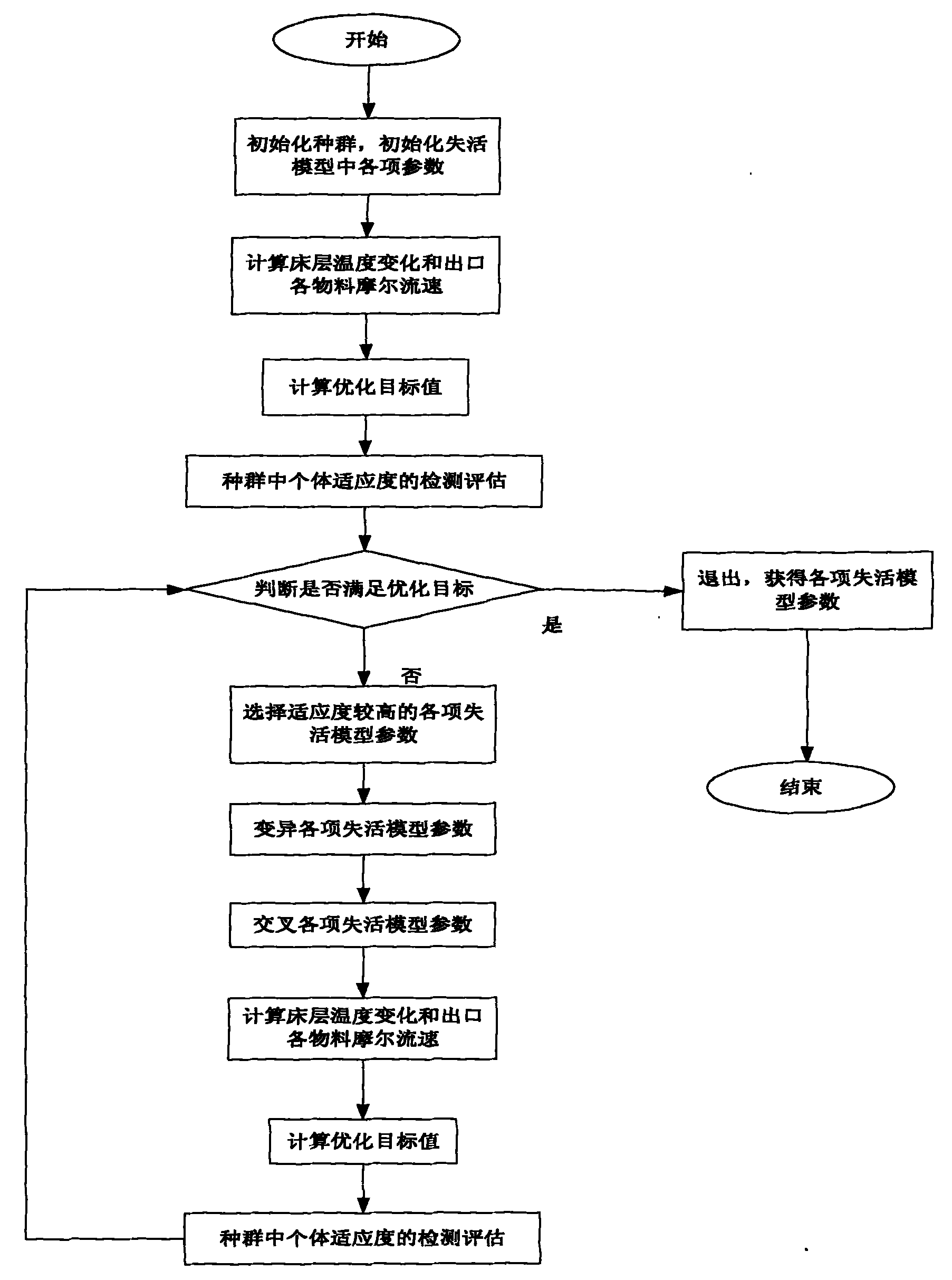

[0025] The present invention will be further described below with reference to the drawings and examples.

[0026] Reaction mechanism and kinetic model

[0027] Laboratory research results of the acetylene catalytic hydrogenation reaction process show that hydrocarbons cover the surface of palladium metal to form two different catalytic centers: A center and E center. The A center is composed of a series of narrow adsorption centers, which can adsorb acetylene and hydrogen, but because they are too narrow to adsorb ethylene, ethylene hydrogenation cannot be carried out; the E center can adsorb all reactants including ethylene, due to the steady state The number of E centers on the catalyst is much smaller than the number of A centers. The hydrogenation rate of acetylene on the F center is negligible, and the main hydrogenation reaction is ethylene. A reaction of π-C2H2 hydrogenation to generate ethane will occur on the A center, and this reaction is first hydrogenated by the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com