Data processing method for automatic burdening of hot-rolling slab

A technology of data processing and automatic batching, applied in data processing applications, instruments, calculations, etc., to achieve the effect of reducing slab inventory, high efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Technical scheme of the present invention is achieved like this, and it comprises the following steps:

[0036] (1) Three database table structures are designed, namely the steel type replacement table, the unowned slab table to be batched, and the batched order table, as follows:

[0037] Steel Substitution Table

[0038] Replaced steel grade code

Replace Steel Code

...

...

[0039] Table of unowned slabs to be batched

[0040] Slab No.

Slab Thickness

Slab width

Slab length

Slab weight

steel code

Hot rolling factory

destination code

...

...

...

...

...

...

...

...

...

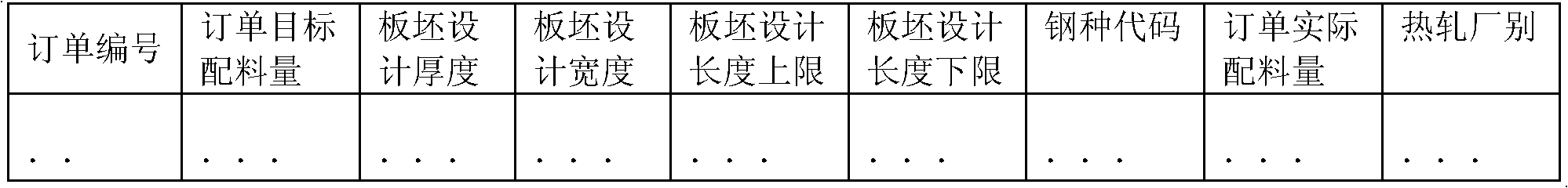

[0041] Pending ingredients order form

[0042]

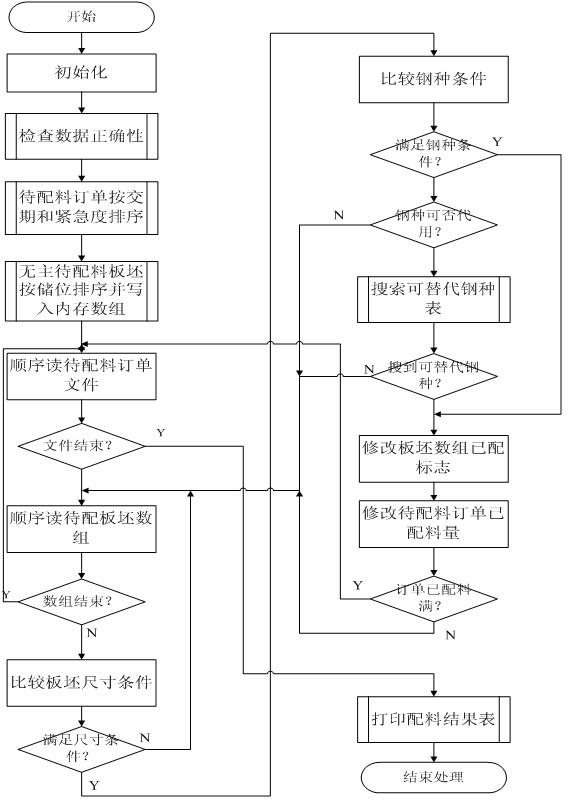

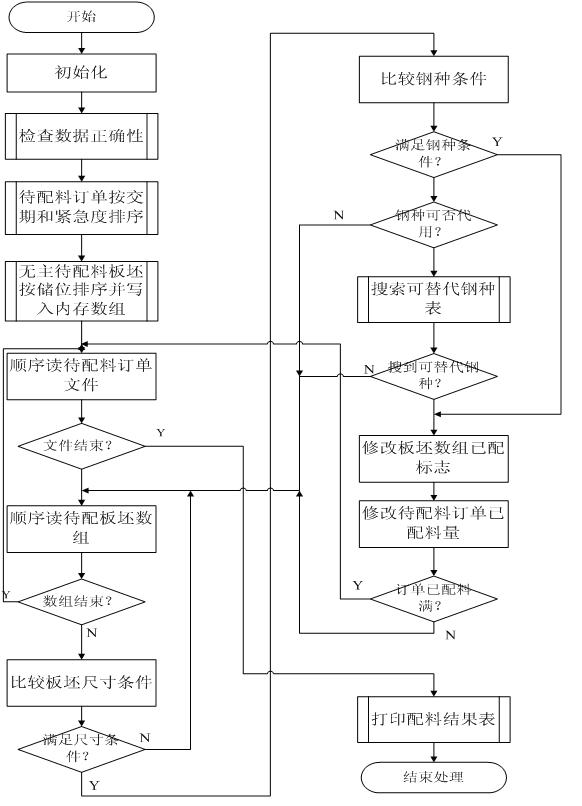

[0043] (2) Process the data in the above database, such as figure 1 Shown:

[0044] ① Input parameters and check the correctness of the input parameters, including:

[0045] Input the steel type to select ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com