Semi-embedded structure of rotor of permanent magnet synchronous motor

A permanent magnet synchronous motor, embedded technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., to achieve the effect of great flexibility, easy process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

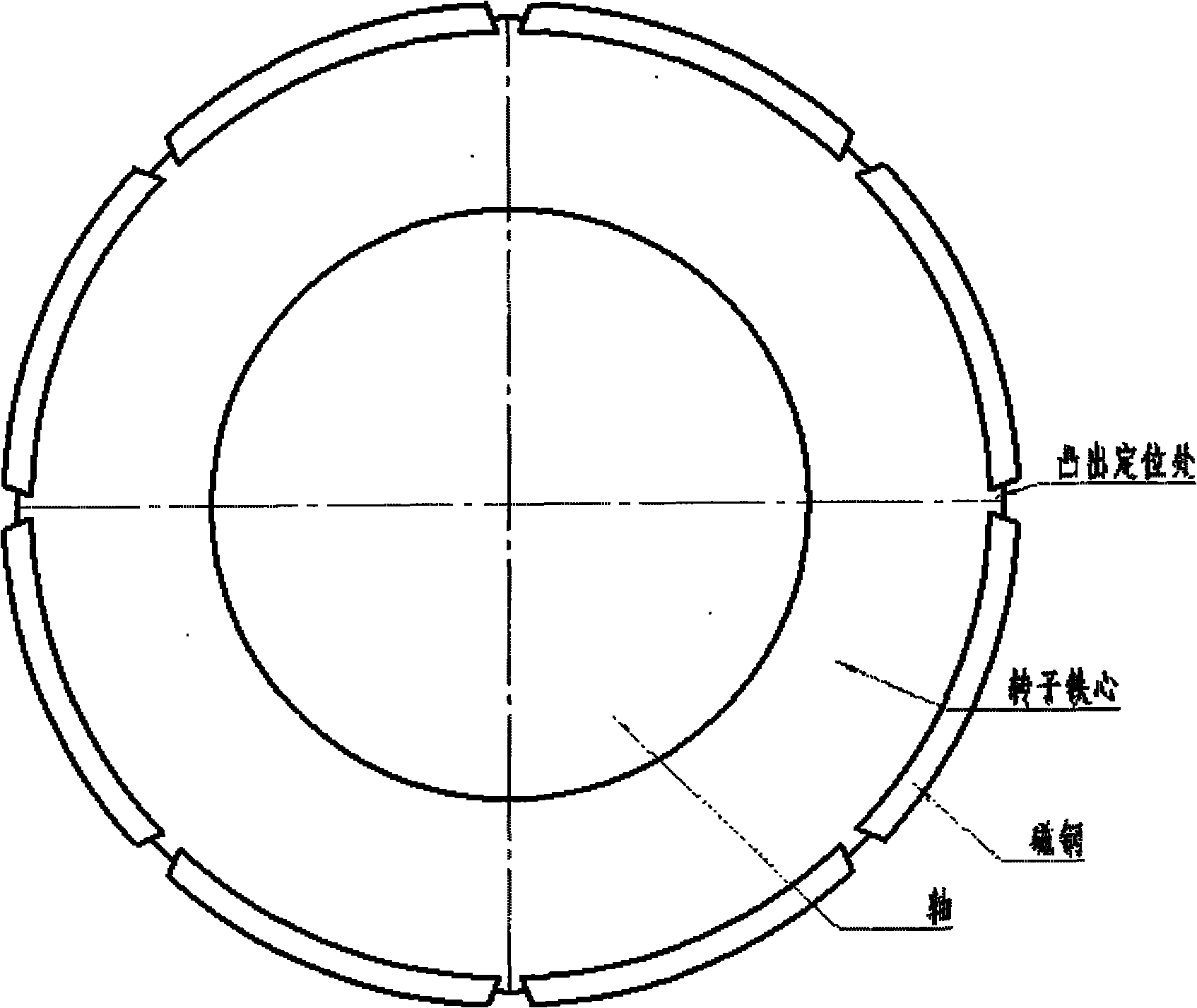

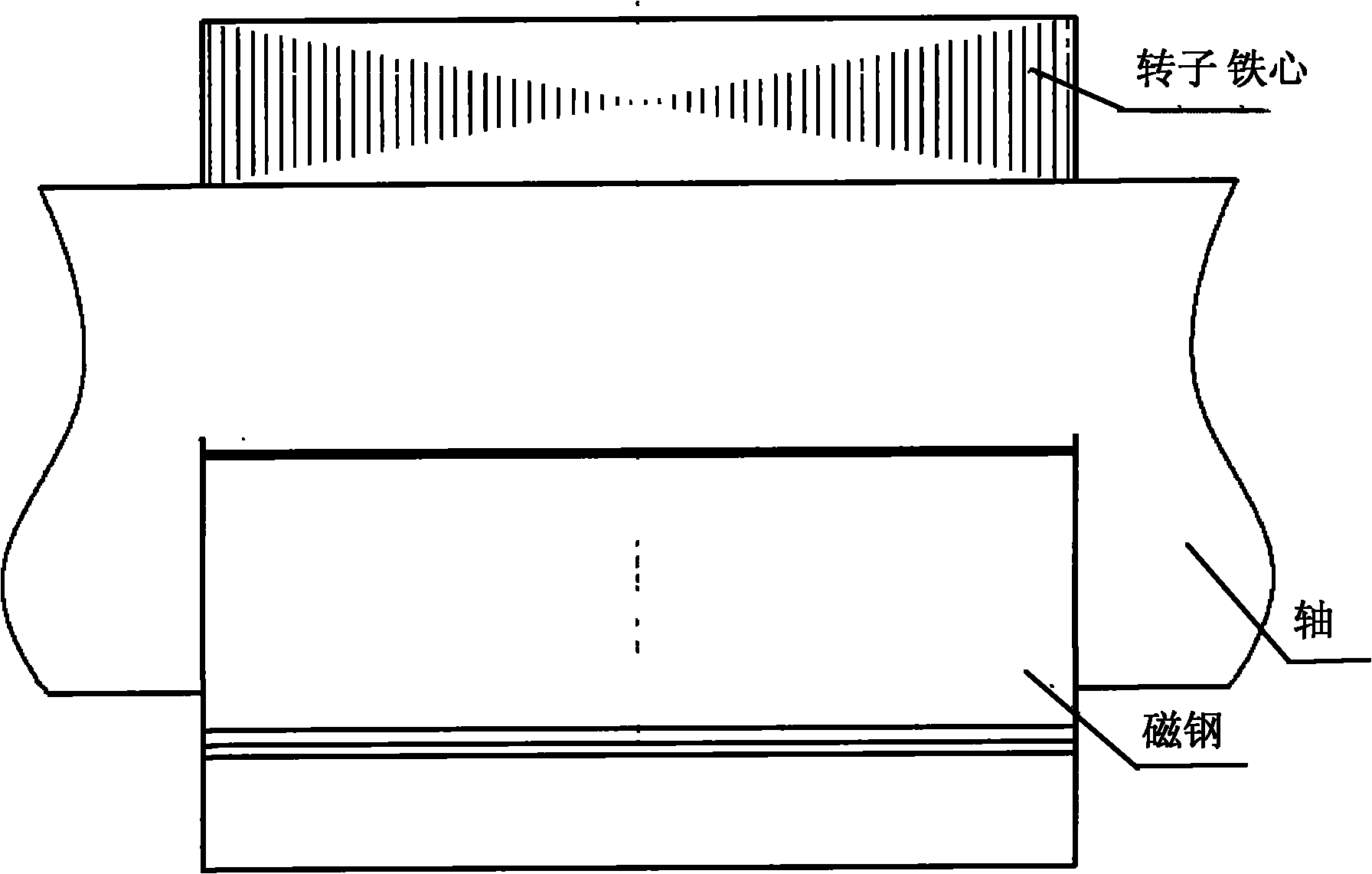

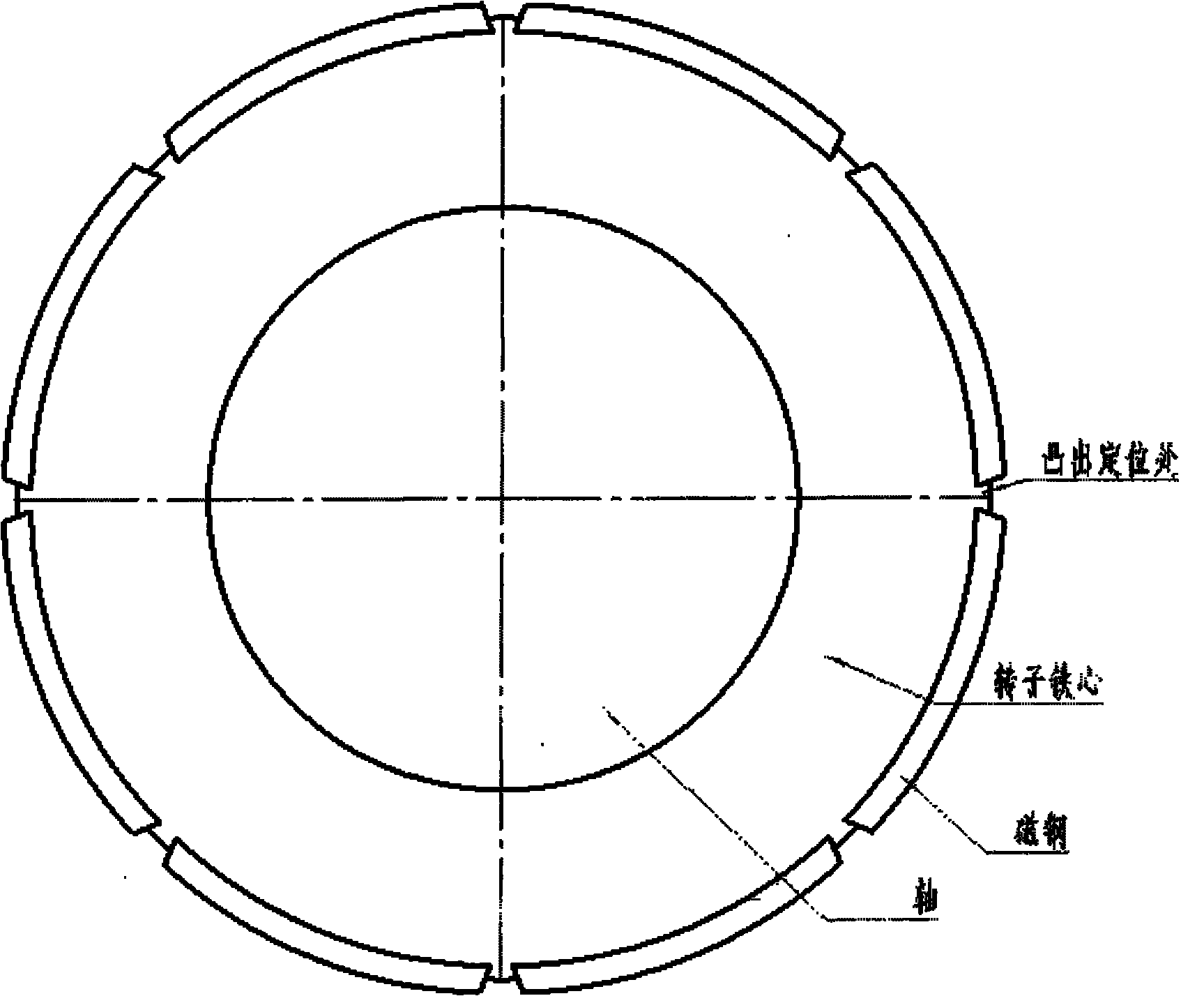

[0013] Such as figure 1 , the outer surface of the rotor core is evenly distributed with protruding rotor teeth, tile-shaped magnetic steel is placed between adjacent rotor teeth, and the magnetic steel is half-embedded in the surface of the rotor core, which is closely attached to the surface of the rotor core, which can be extremely Greatly reduce the large magnetic flux leakage generated by the embedded, the iron cores on both sides clamp it, and apply general structural glue and curing agent on the inner surface of the magnetic steel and rotor core, so as to ensure the smooth operation of the motor above 10,000rpm.

[0014] Utilize the technical solution described in the present invention, or those skilled in the art design a similar technical solution under the inspiration of the technical solution of the present invention, and achieve the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com