Method for determining thicknesses of solid-liquid slag lubricating films on basis of temperature measuring continuous-casting mold of thermoelectric couple

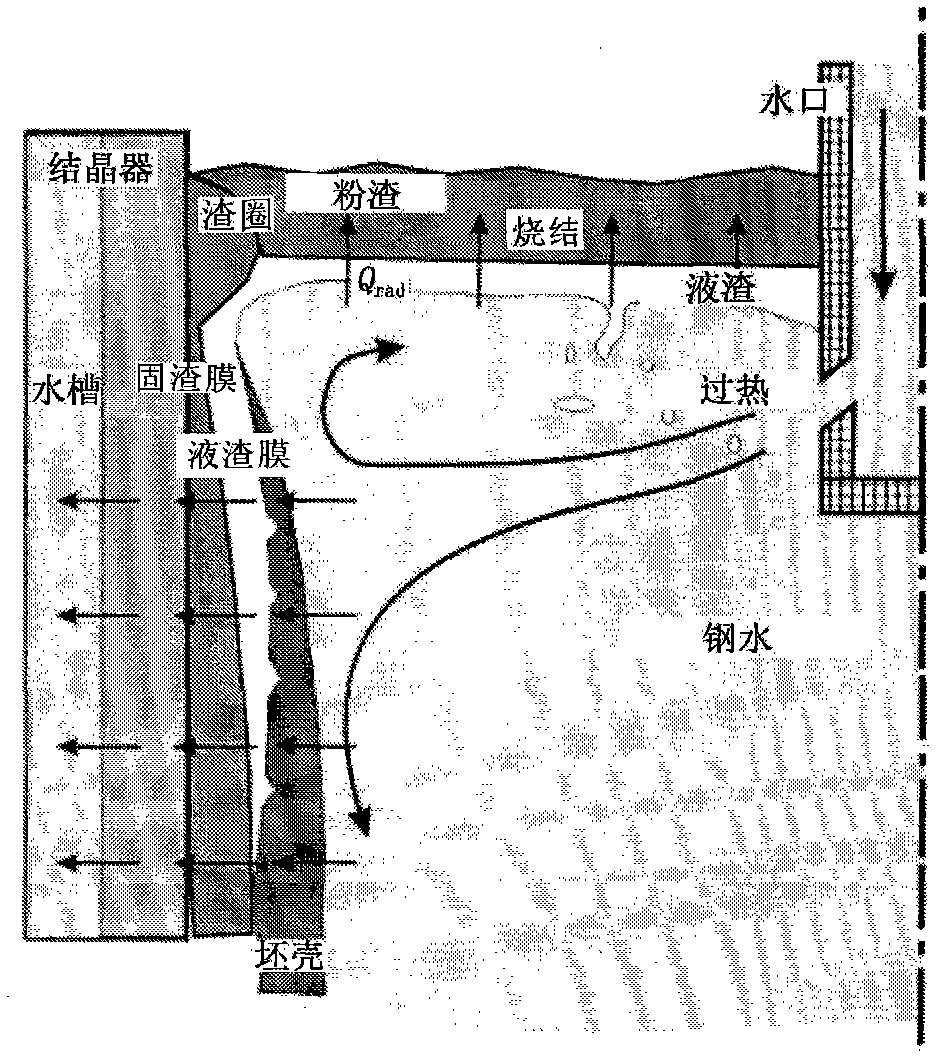

A continuous casting mold and a technology for determining the method, which is applied in the field of determining the thickness of the solid-liquid slag lubricating film of the continuous casting mold based on thermocouple temperature measurement, and can solve problems such as the lack of calculation methods for the thickness of the liquid slag film in the meniscus area of the continuous casting mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

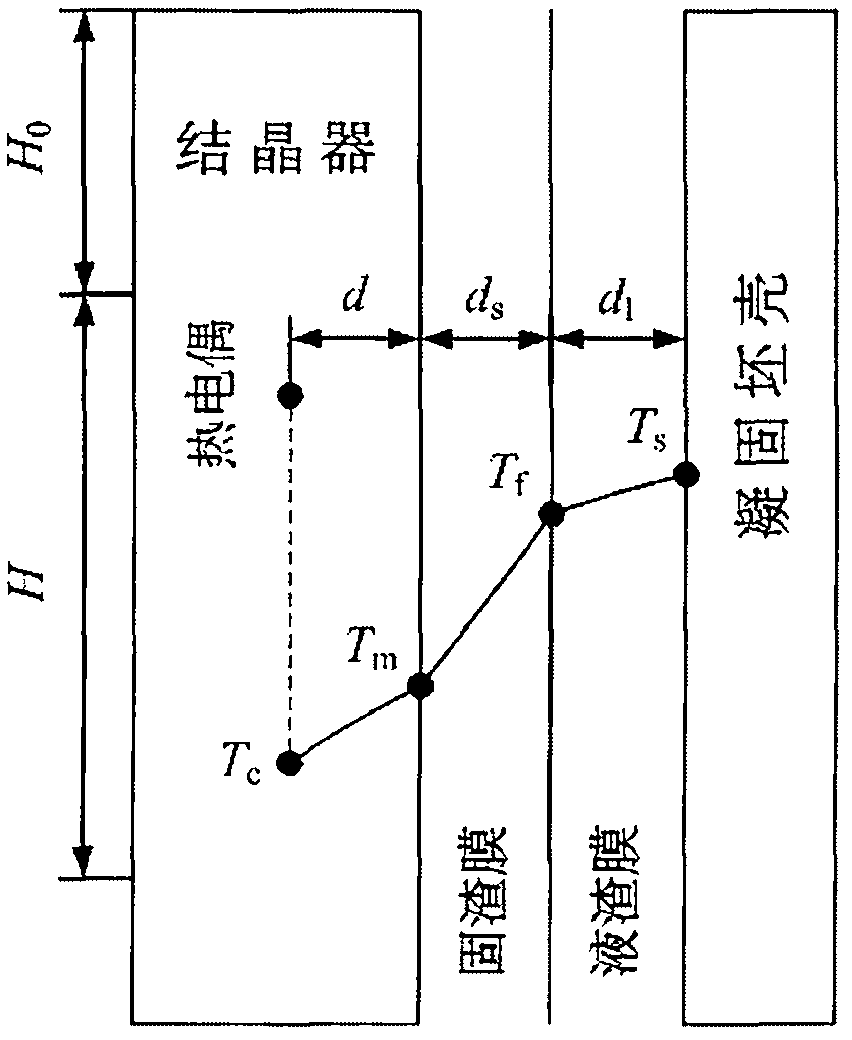

[0067] The present invention establishes a mathematical model based on the above-mentioned derivation equation, and realizes online calculation of the thickness of the mold slag lubricating film in the meniscus region in combination with the temperature detected by the thermocouple in the meniscus region. Now, the embodiment is described in detail for the case of on-site casting of low-carbon steel.

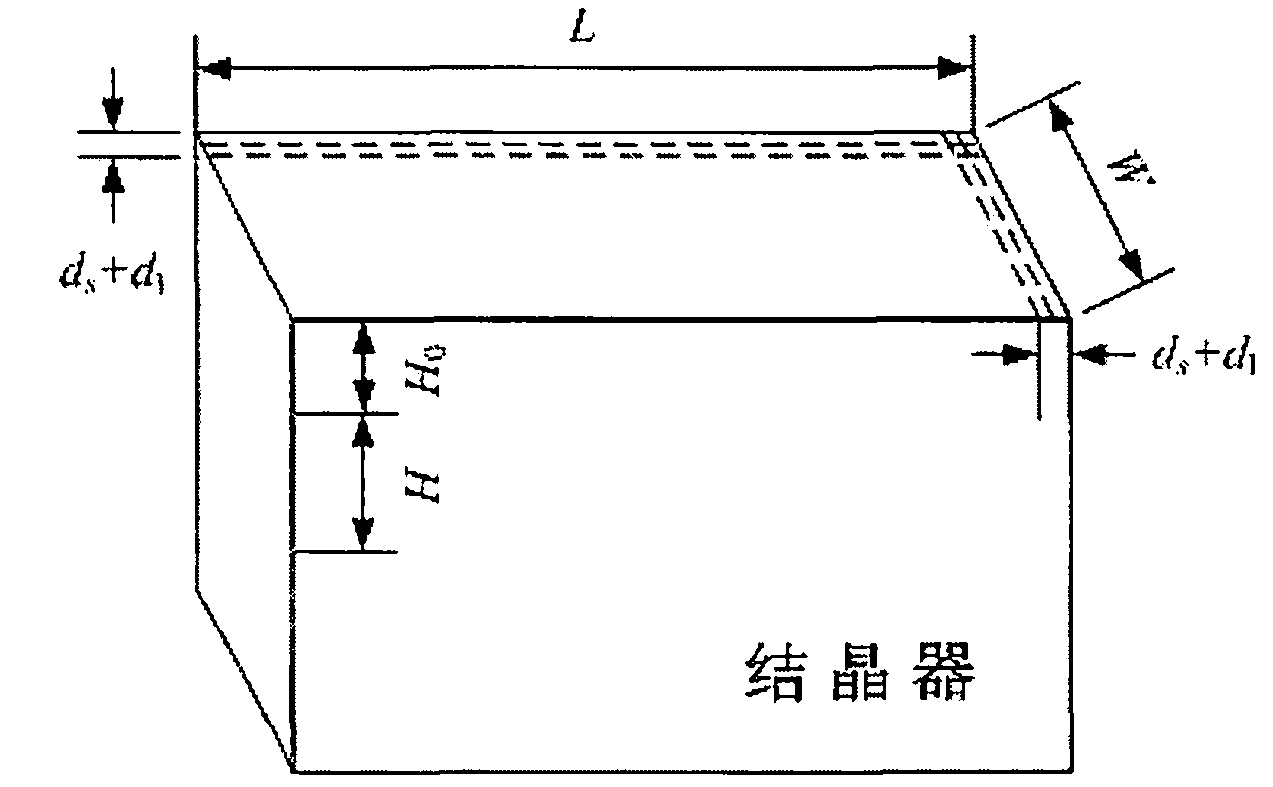

[0068] A method for determining the thickness of the mold slag lubricating film of a continuous casting mold based on the temperature measurement of the meniscus thermocouple is carried out as follows: Figure 4 Shown:

[0069] Step 1. Get initial data

[0070] 1. Determine the meniscus height H

[0071] The height of the meniscus is the length of the slag channel, which is obtained from the capillary constant equation (15);

[0072] H = 2 σ s - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com