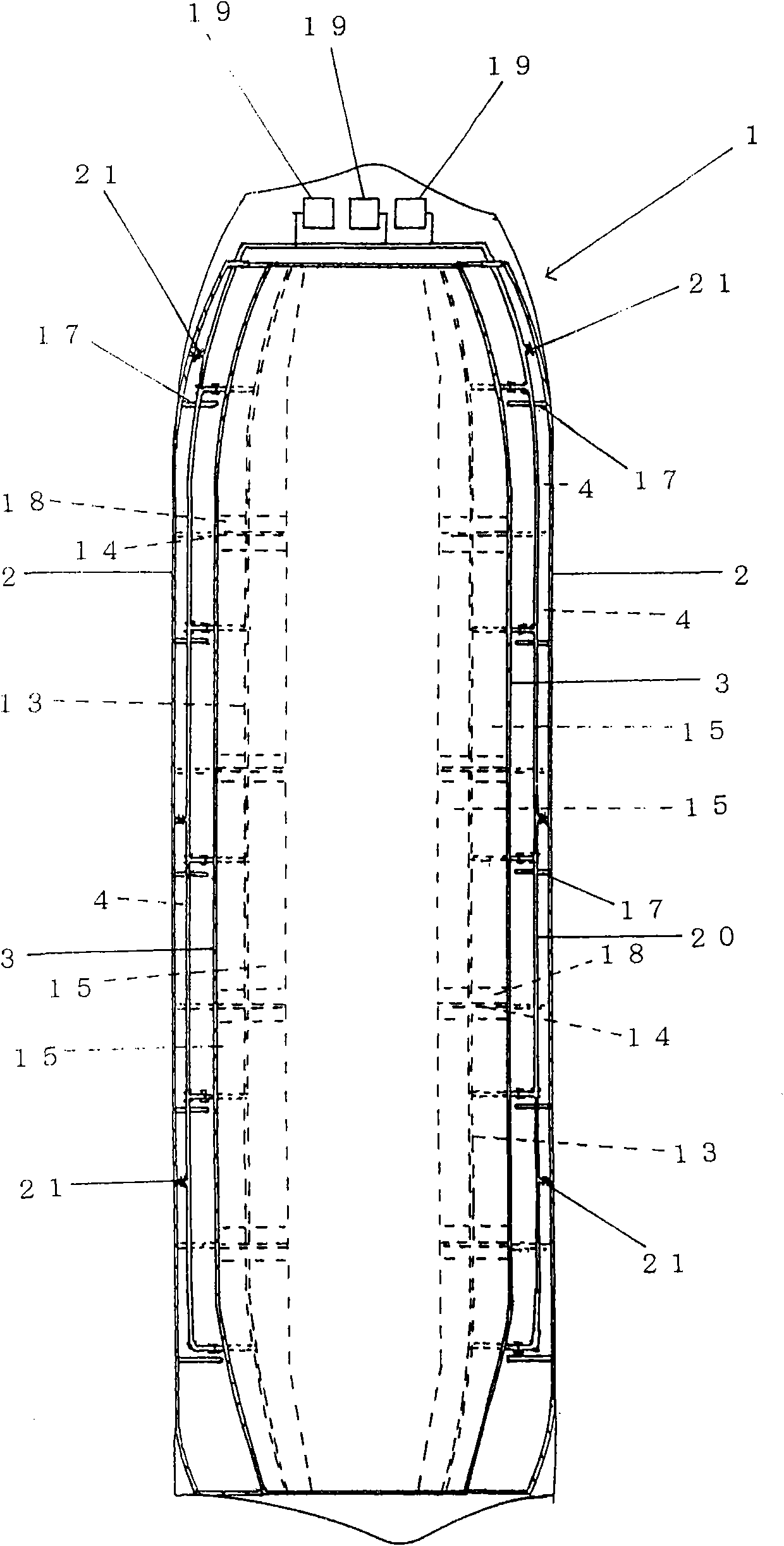

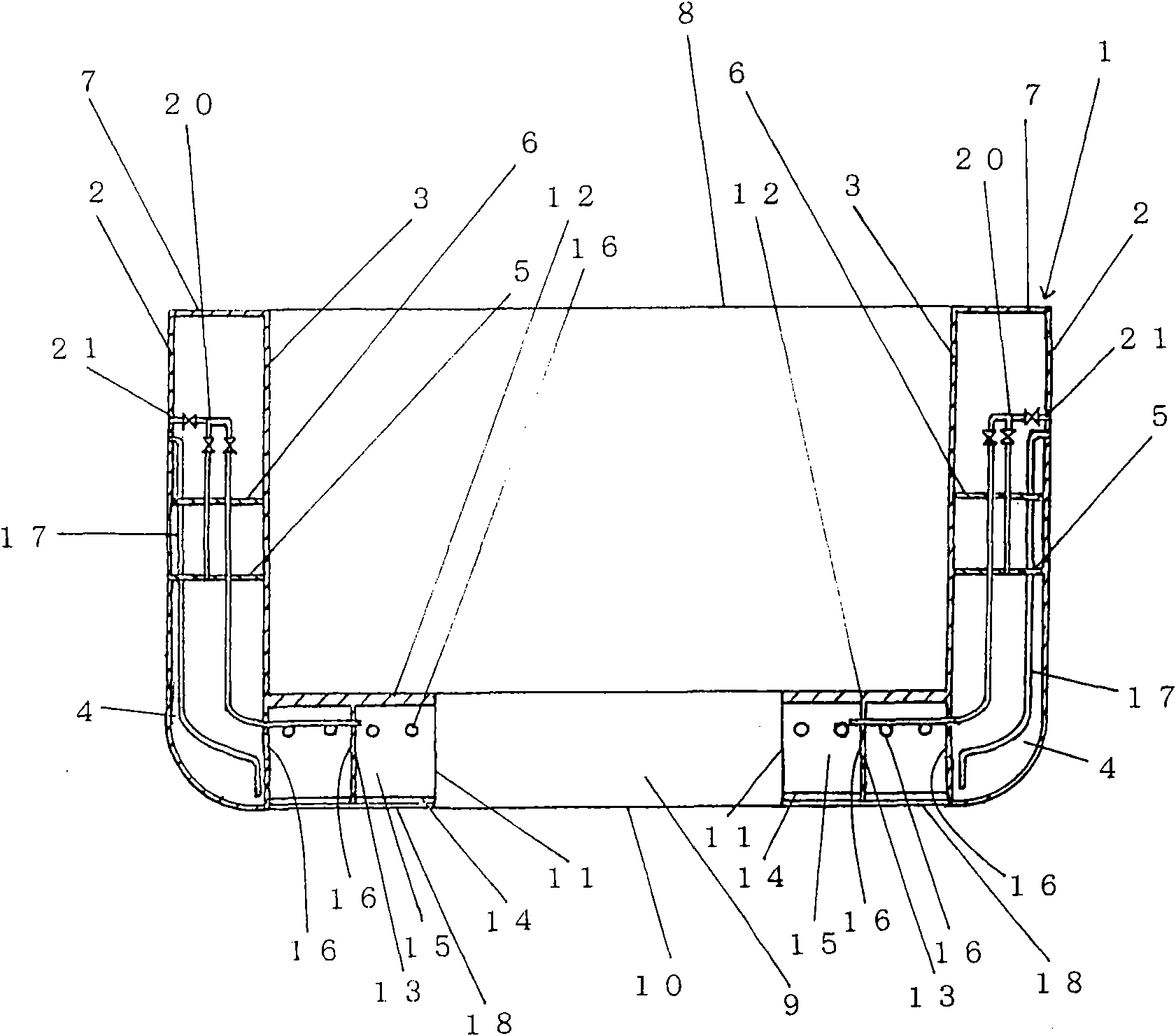

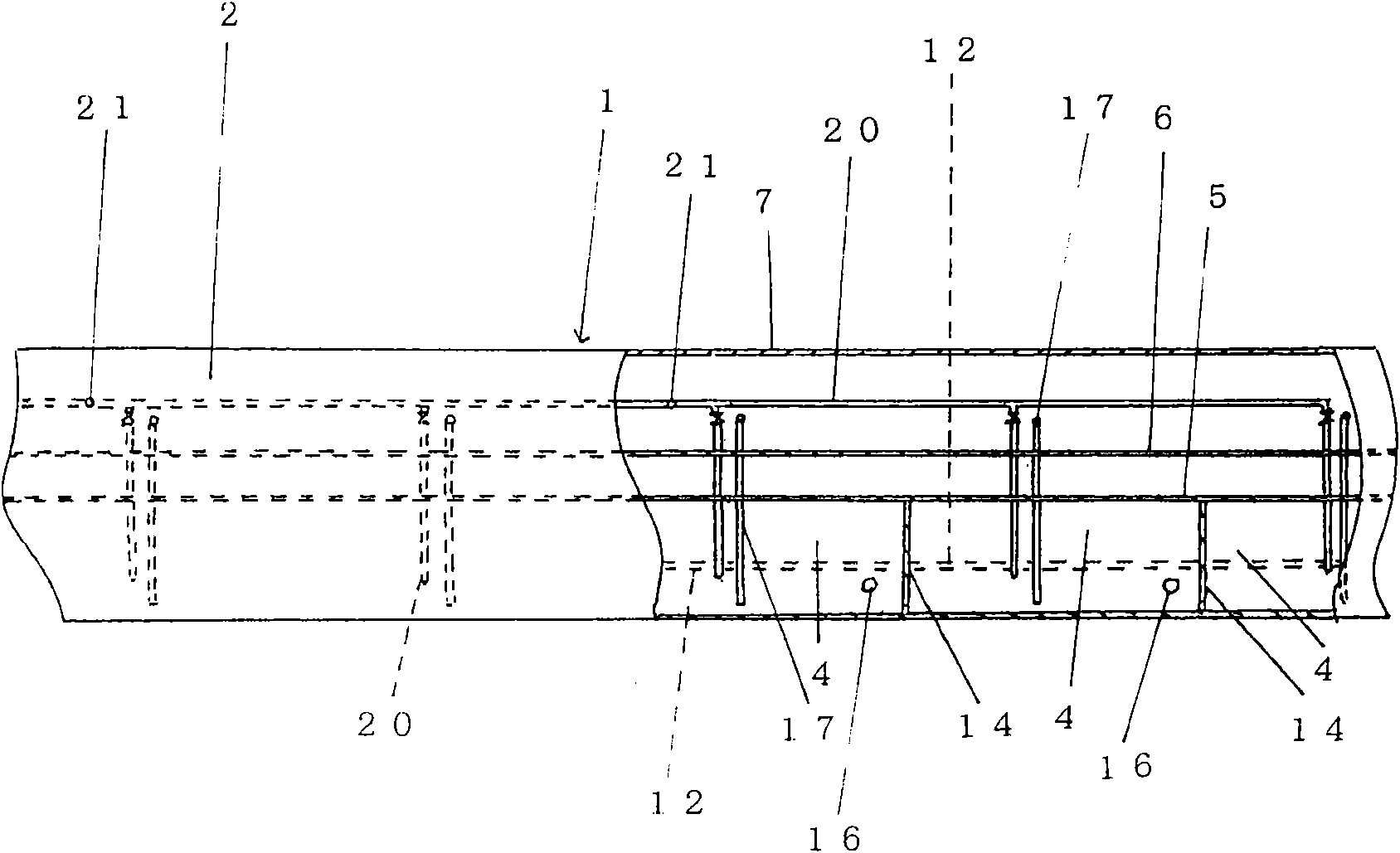

Ballast-free ship

A technology for water boats and hulls, which is applied in the direction of hulls, hulls, and hull parts, etc. It can solve the problems of higher load tax, increased fuel volume, and easy corrosion of pipelines by seawater, so as to prevent the roll of the hull and avoid The effect of raising the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] By opening the other end of the vent pipe with both ends open at the same level as the height direction of the upper surface of the fairing plate, the sea surface position of the seawater entering the air cushion chamber will not be located below the upper surface of the fairing plate so that the hull The center of gravity of the ship will not rise above a certain position, and even in bad weather, the rolling of the hull can be prevented to avoid the danger of being killed such as capsizing. In addition, the balance of the hull is adjusted by supplying or exhausting compressed air according to the weight of the empty or loaded cargo, avoiding dangers such as rolling and capsizing of the ship, and preventing seawater from adhering to the bottom shell of the air cushion chamber to prevent the bottom shell from being damaged. of corrosion. In addition, the air cushion chamber can be visually confirmed from the bottom of the hull in the dock (duck) very easily, and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com