Fixed bed slag gasification furnace

A technology of slag gasification and fixed bed, applied in the field of slag gasifier, can solve problems such as poor gasification effect, unreasonable gasifier lining structure, poor safety performance, etc., and reduce maintenance times and maintenance costs , increase safety and reliability, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

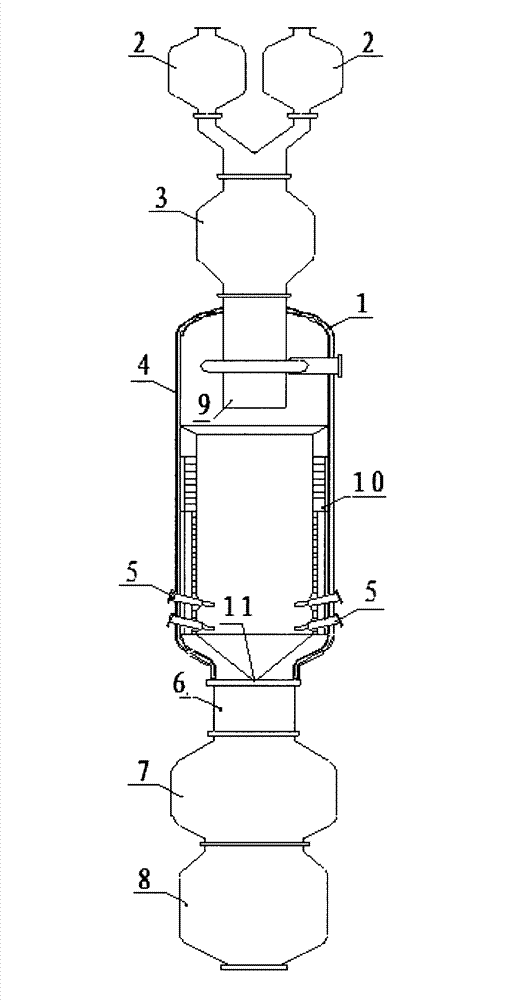

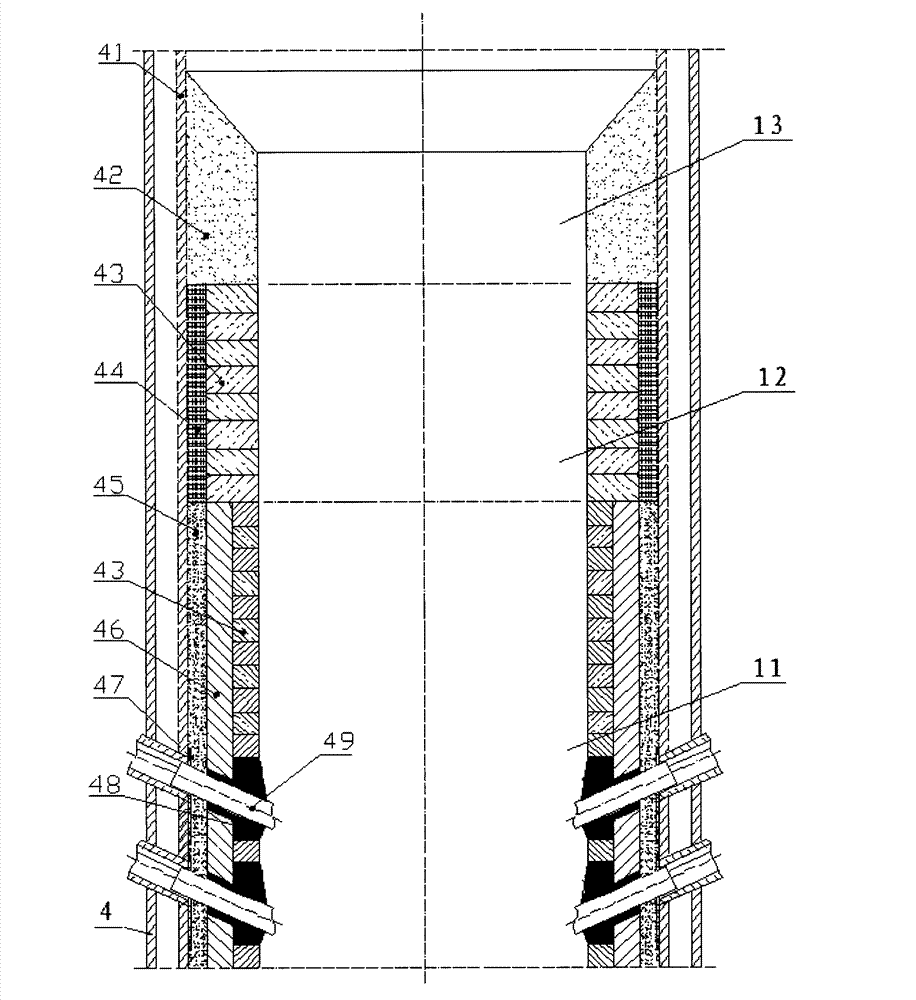

[0025] Such as figure 1 As shown, the fixed bed slag gasifier of the present invention is used to process carbonaceous substances, and it consists of a raw material lock hopper 2, a raw material buffer bin 3, a furnace body 4, a control nipple 6, a slag quenching chamber 7, and a slag lock 8 and other parts. A composite furnace lining 10 is provided inside the furnace body 4 , the lower part of the furnace body 4 is equipped with a nozzle 49 , the upper end of the composite furnace lining 10 is provided with a gas collecting device 9 , and a slagging device 11 is installed under the furnace body 4 .

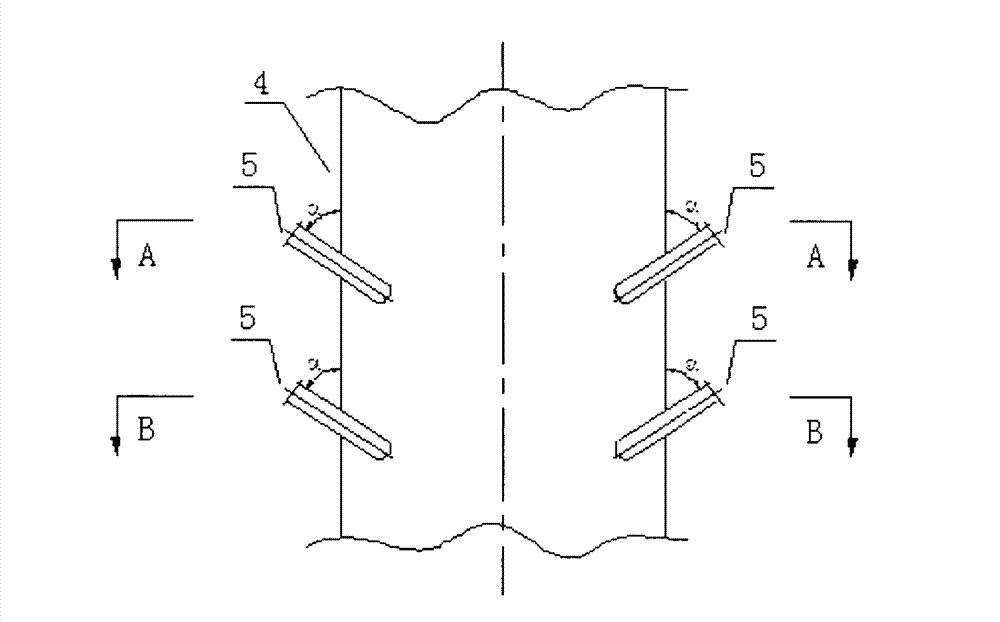

[0026] In the prior art, the furnace body is usually divided into three regions according to the temperature of the bed, such as figure 2 As shown in the lower area and the slag pool area 11, when the gasifier processes materials, the temperature of the materials in the furnace in this area is relatively high. Due to the intense exothermic reaction between the carbonaceous mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com