Construction method for preventing repaired crack from cracking

A construction method and post-repair technology, applied in building maintenance, road repair, bridge repair, etc., can solve problems such as falling off, chipping and cracking, aging of asphalt and other repair materials, and achieve good scalability and prevent cracking again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments.

[0012] A construction method for sealing and repairing road cracks with anti-detachment and anti-cracking, comprising the following steps:

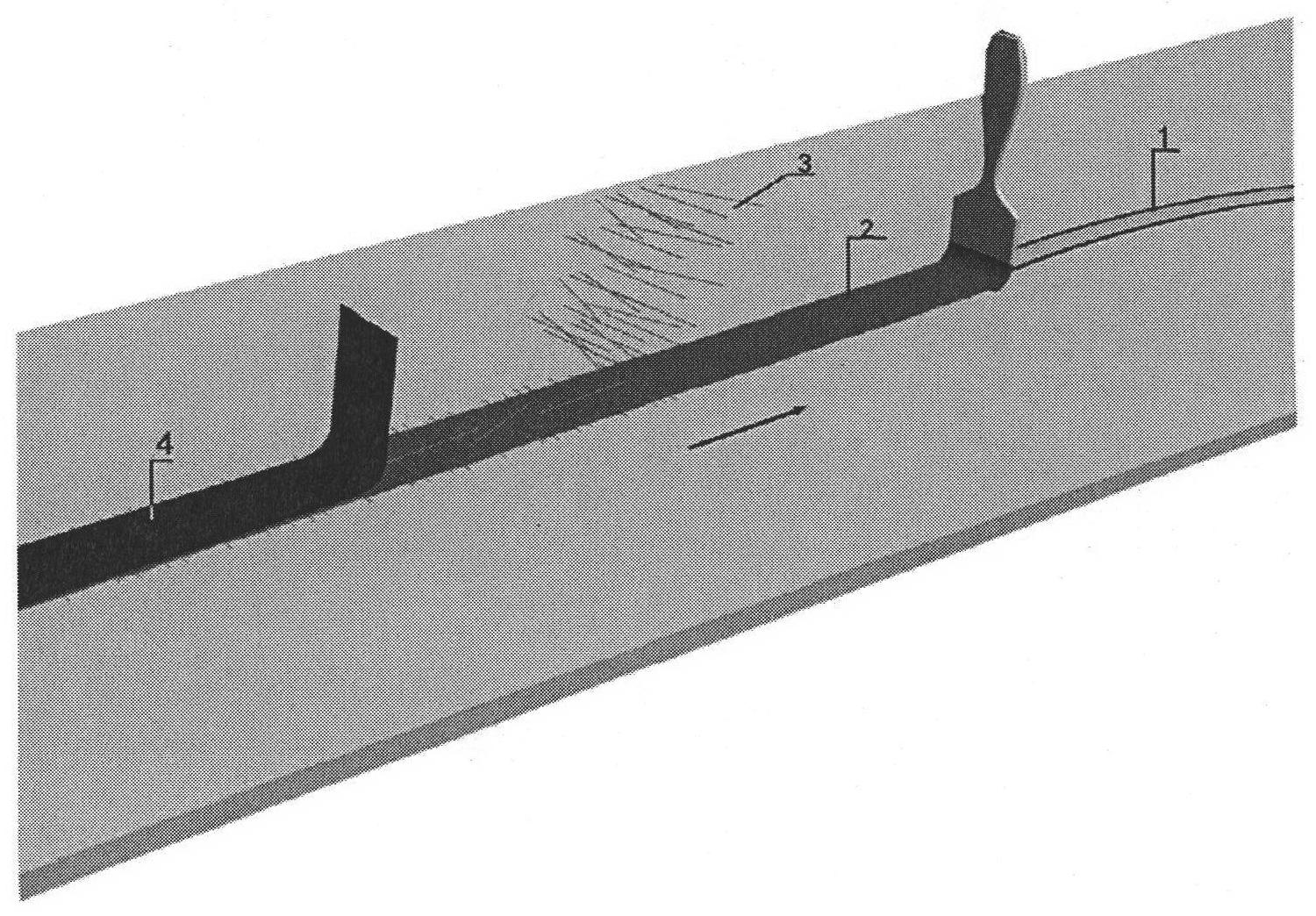

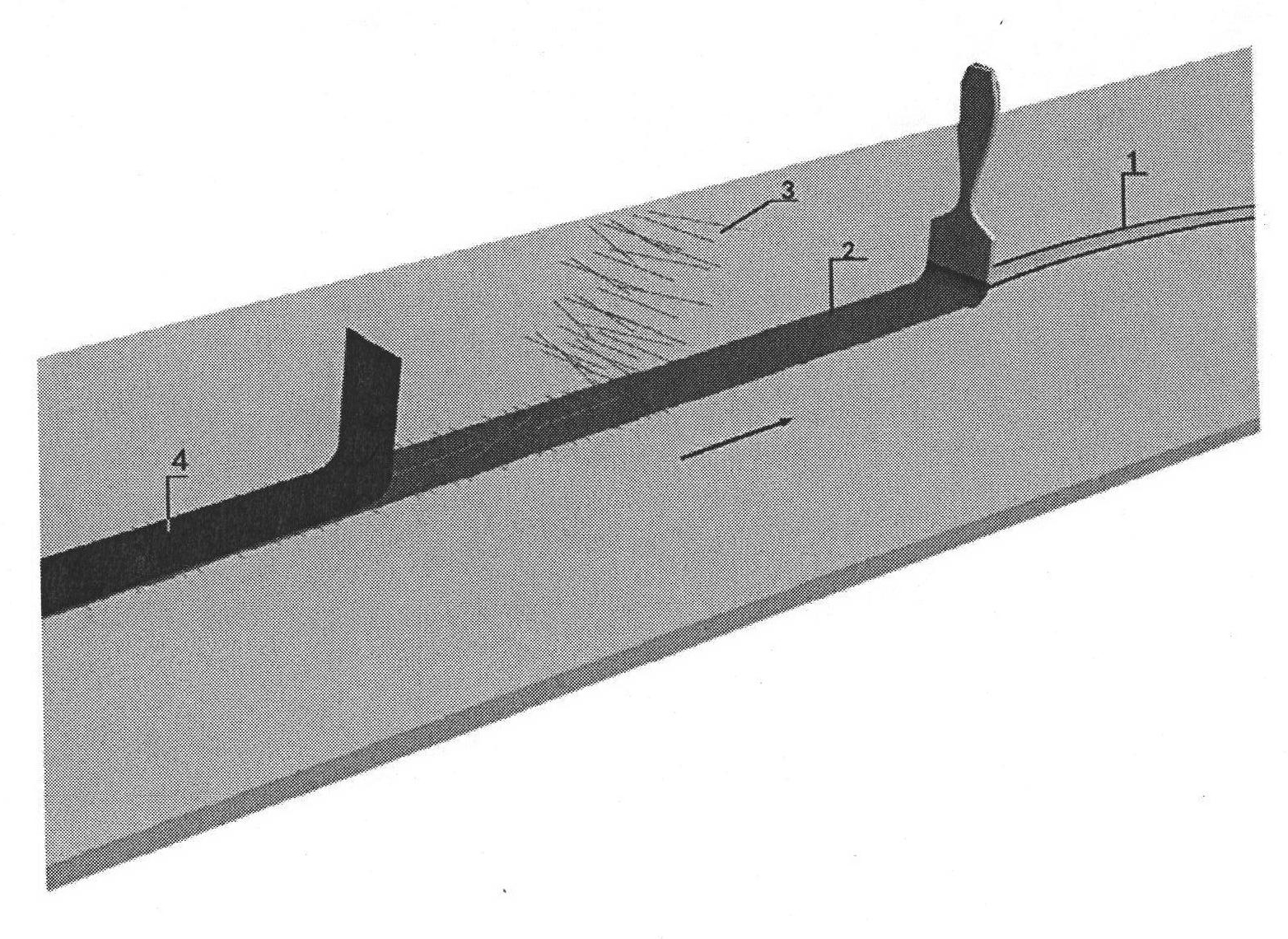

[0013] a. Paint the crack 1 with a solvent 2 that can fuse both dust and asphalt to eliminate the bond between the material and the crack that affects the sealing and repairing of the crack;

[0014] b. Sprinkle high-strength fibers 3 of suitable length and size on the crack surface. The longitudinal direction of most fibers should intersect with the crack direction, and overlap each other or form a network structure;

[0015] c. Fill the cracks with asphalt or polymer sizing material, or paste the tape-shaped sealing and repairing material 4, (the fibers and the sealing and repairing material are automatically bonded together), and spread suitable sand particles.

[0016] Steps b and c can be performed in reverse, that is, first pour asph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com