Side-to-side thermal deashing method for rotary air preheater

A technology of air preheater and rotary type, which is applied in the direction of combustion method, solid residue removal, lighting and heating equipment, etc. It can solve the problems of improving the denitrification rotary air preheater and reducing the design efficiency of power plant boilers, etc., and achieves the improvement Design efficiency, reduce fan power consumption, and avoid abnormal rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

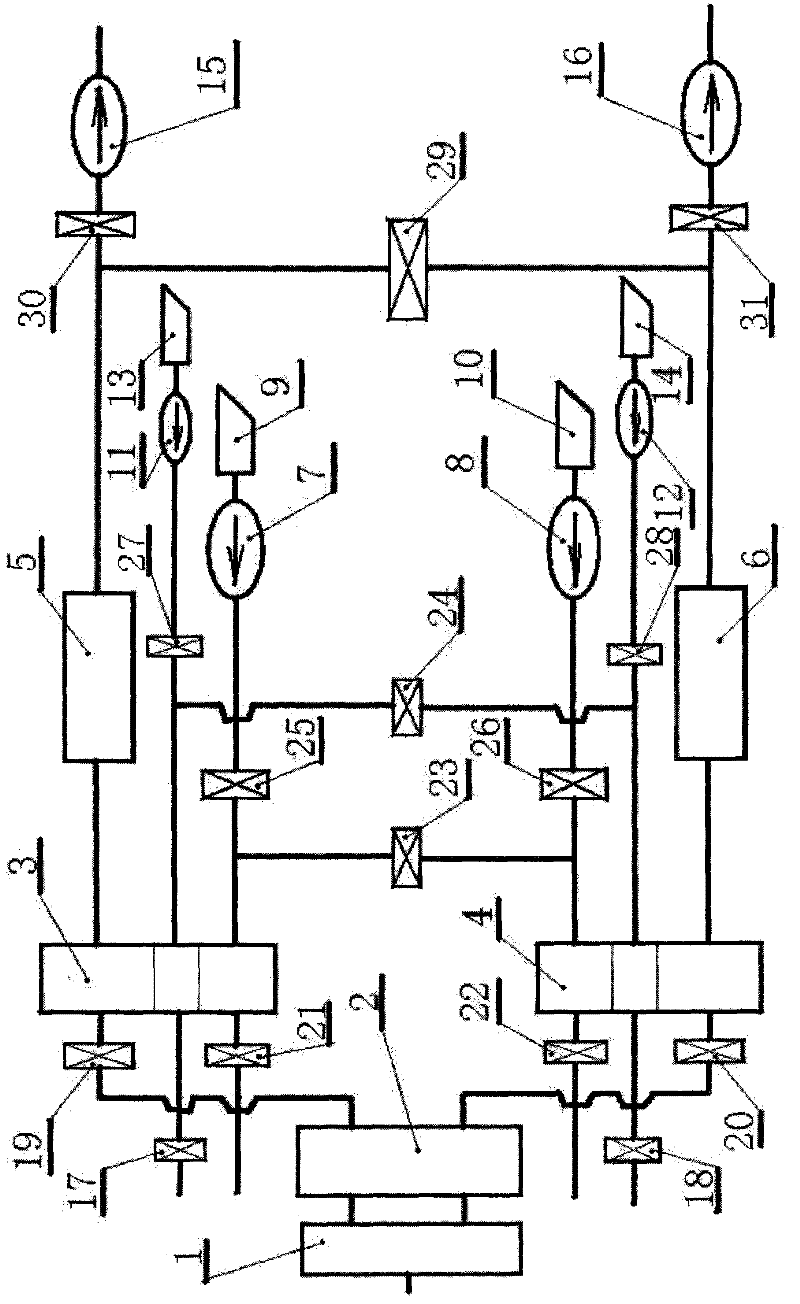

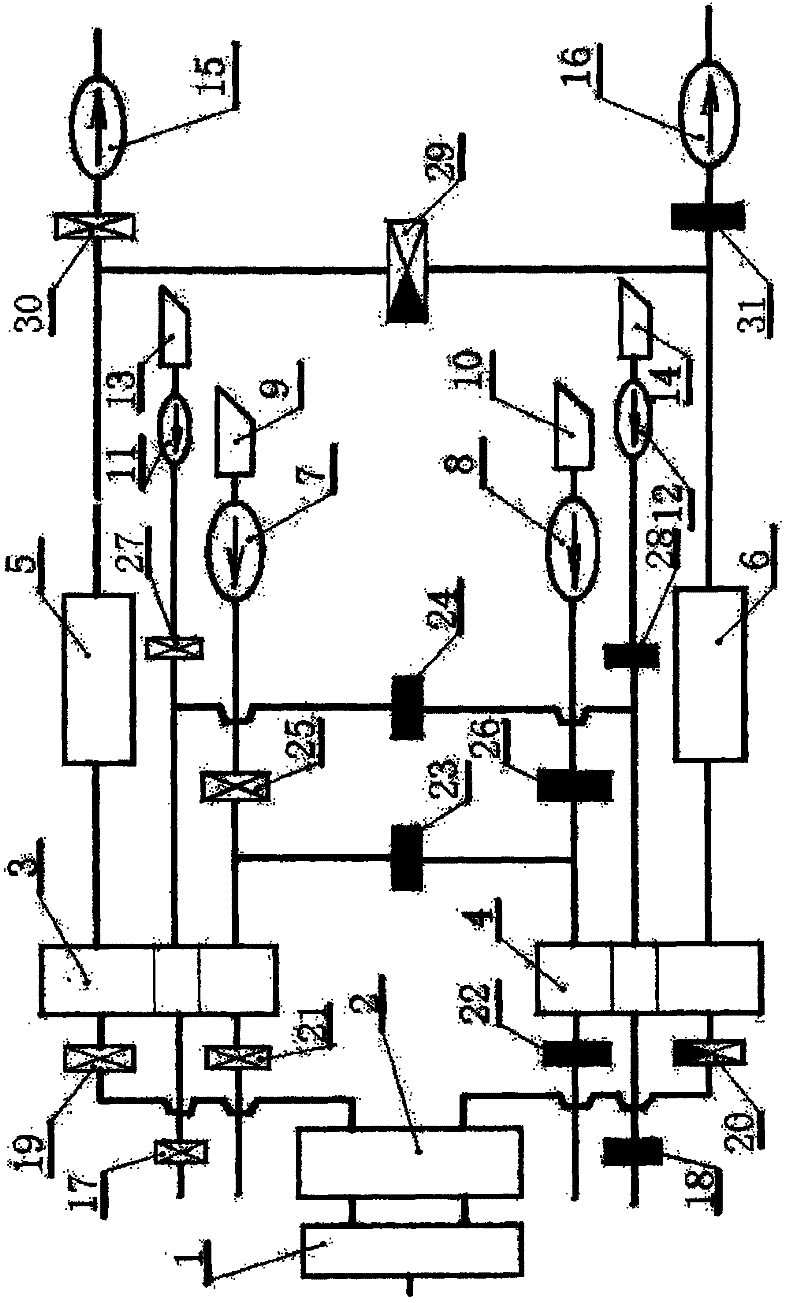

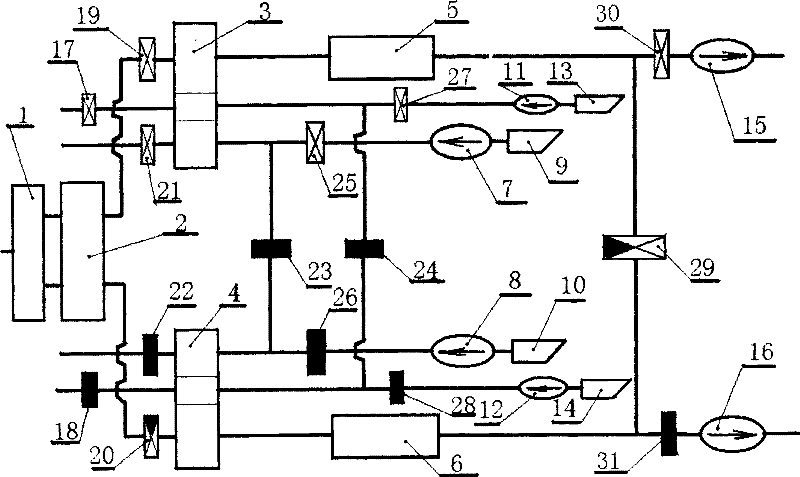

[0039] The preparatory conditions for the implementation of side-by-side hot ash cleaning of the rotary air preheater should meet the following requirements:

[0040] a. The boiler load of the power station is lower than 60% of the rated load but higher than the minimum load of the boiler without fuel injection and stable combustion;

[0041] b. A side cold primary air inlet door (27), B side cold primary air inlet door (28), A side hot primary air outlet door (17), B side hot primary air outlet door (18), A side cold secondary air Entrance door (25), B side cold secondary air inlet door (26), A side hot secondary air outlet door (21), B side hot secondary air outlet door (22), cold primary air AB side liaison door ( 24) The AB side contact door (23) of the cold secondary air, the A side induced draft fan entrance door (30), and the B side induced draft fan entrance door (31) can be closed tightly;

[0042] c. The electric actuators of the flue gas inlet door (19) on the A si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com