Aluminum foil test method for performance of ultrasonic cleaner

A testing method, ultrasonic technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve problems such as the speed of corrosion, and achieve the effect of effective data support and effective experimental verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

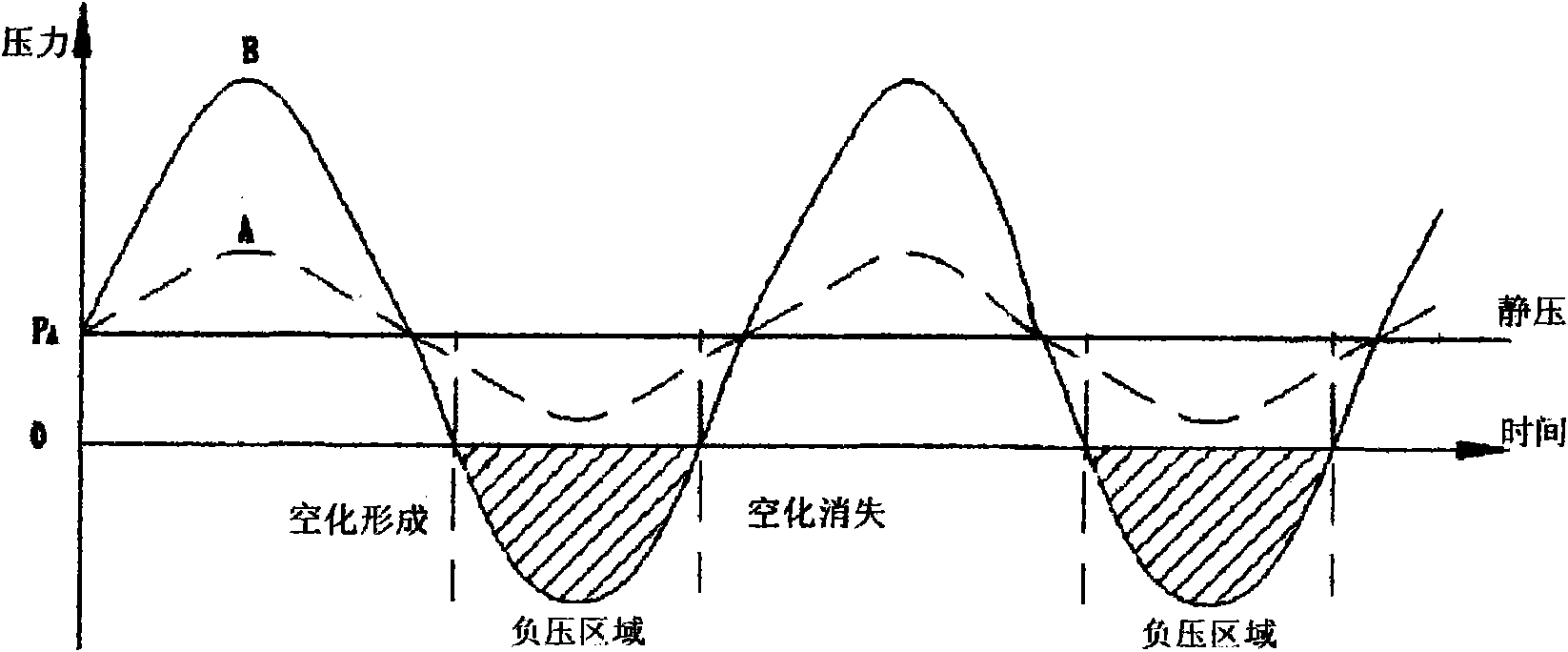

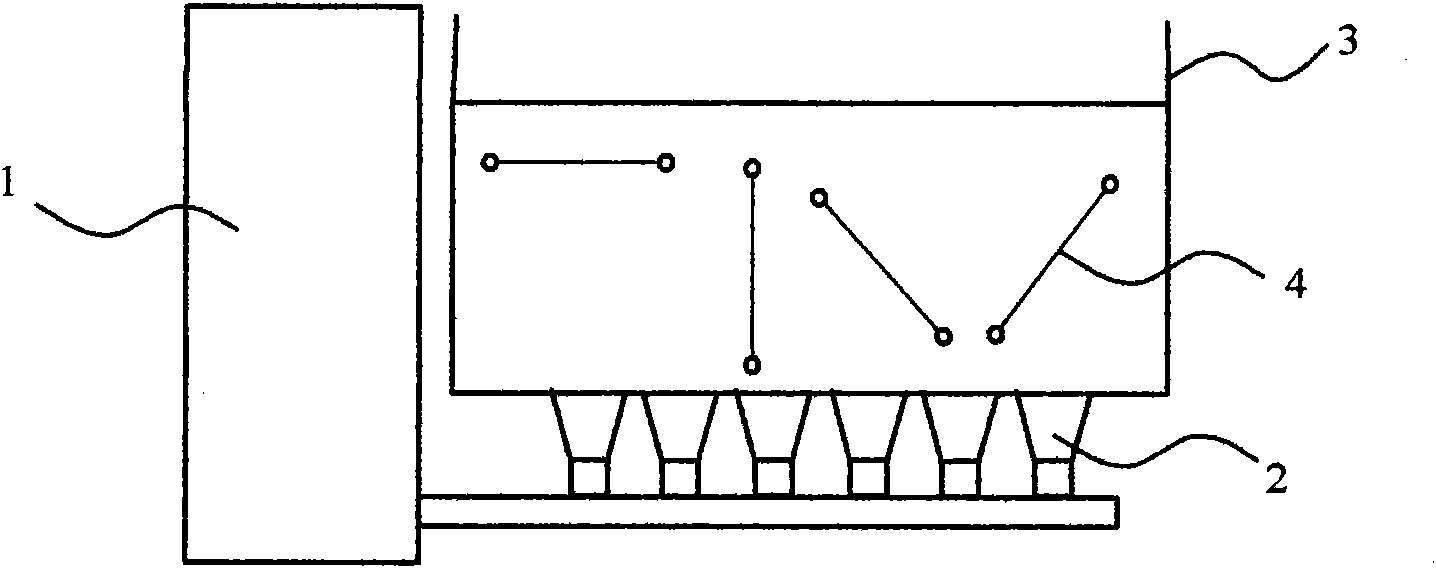

[0024] Such as figure 2 As shown, the ultrasonic cleaning machine is mainly composed of an ultrasonic generator 1, an ultrasonic transducer 2 and a cleaning tank 3. When cleaning the workpiece, put the cleaning liquid into the cleaning tank, and apply ultrasonic waves in the tank. The cleaning liquid can usually use ss-25 motor cleaning liquid, or other types of cleaning liquid products. After the ultrasonic generator converts the 50Hz alternating current into an ultrasonic frequency (such as 44KHz) electrical oscillation signal, it is sent to the ultrasonic transducer at the bottom of the cleaning tank through the output cable, and the ultrasonic frequency electrical oscillation signal is converted into an ultrasonic frequency by the transducer. Mechanically vibrated and launched into the cleaning fluid. The cleaning tank is a container for cleani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com