Vacuum high-temperature high-speed friction-wear testing device

A friction and wear test and vacuum technology, applied in the direction of testing wear resistance, etc., can solve problems such as hidden safety hazards, no protective measures, inability to meet use requirements, etc., and achieve the effect of safe and reliable recovery and widening the experimental speed range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

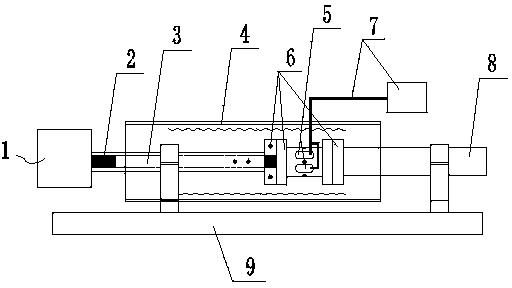

[0014] The specific embodiment of the present invention is described below: a vacuum high-temperature high-speed friction and wear test device, including a hydraulic power system 1, a bullet 2, a propulsion system 3, a vacuum heating system 4, a friction pair loading system 6, a data acquisition system 7, a sample The recovery system 8 and the support frame 9, the hydraulic power system 1 is a hydraulic pump, the hydraulic pump is provided with a control valve, and the power generated by the hydraulic pump is transmitted to the bullet 2 through the hydraulic control valve; the propulsion system 3 is installed on the hydraulic power system The launch tube of the launch tube is provided with a detonator that can measure the firing speed of the bullet 2; the friction pair loading system 6 includes a force ring, a friction pair stuck in the force ring and an annular force-measuring ring installed on the force ring The friction pair includes the test sample fixed on the force ring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com