Wire harness

A wire harness and wire technology, applied in the field of wire harnesses, can solve problems such as peeling, unidentifiable wires, and difficult to identify wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

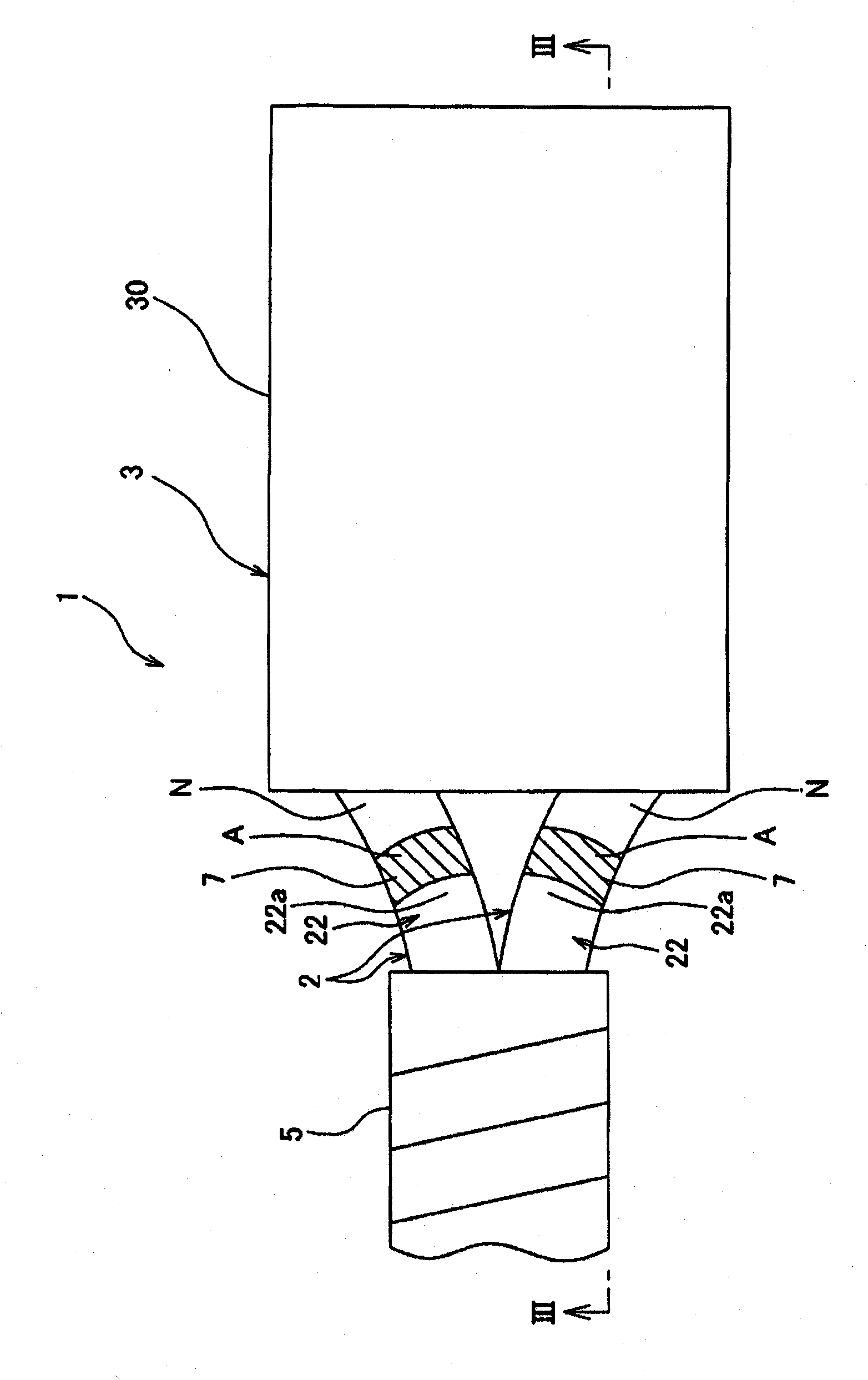

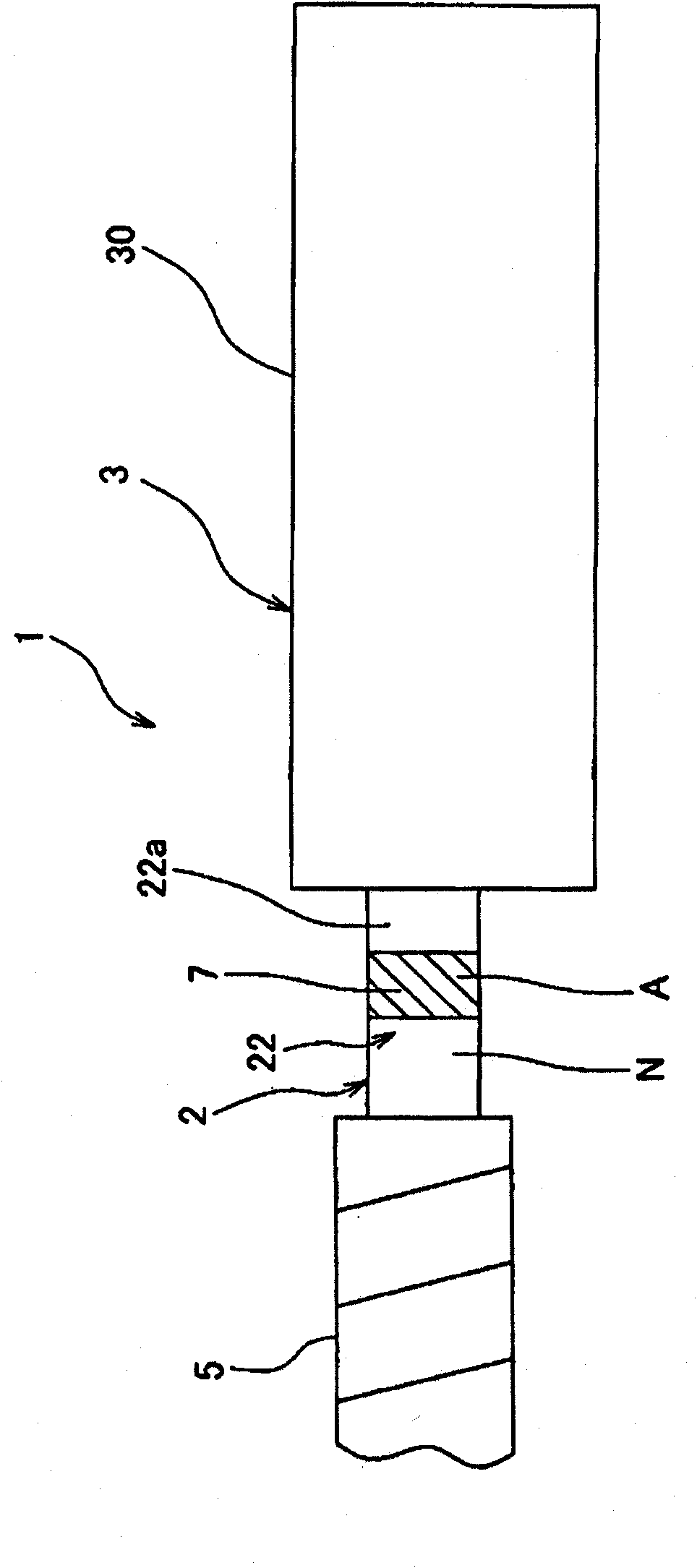

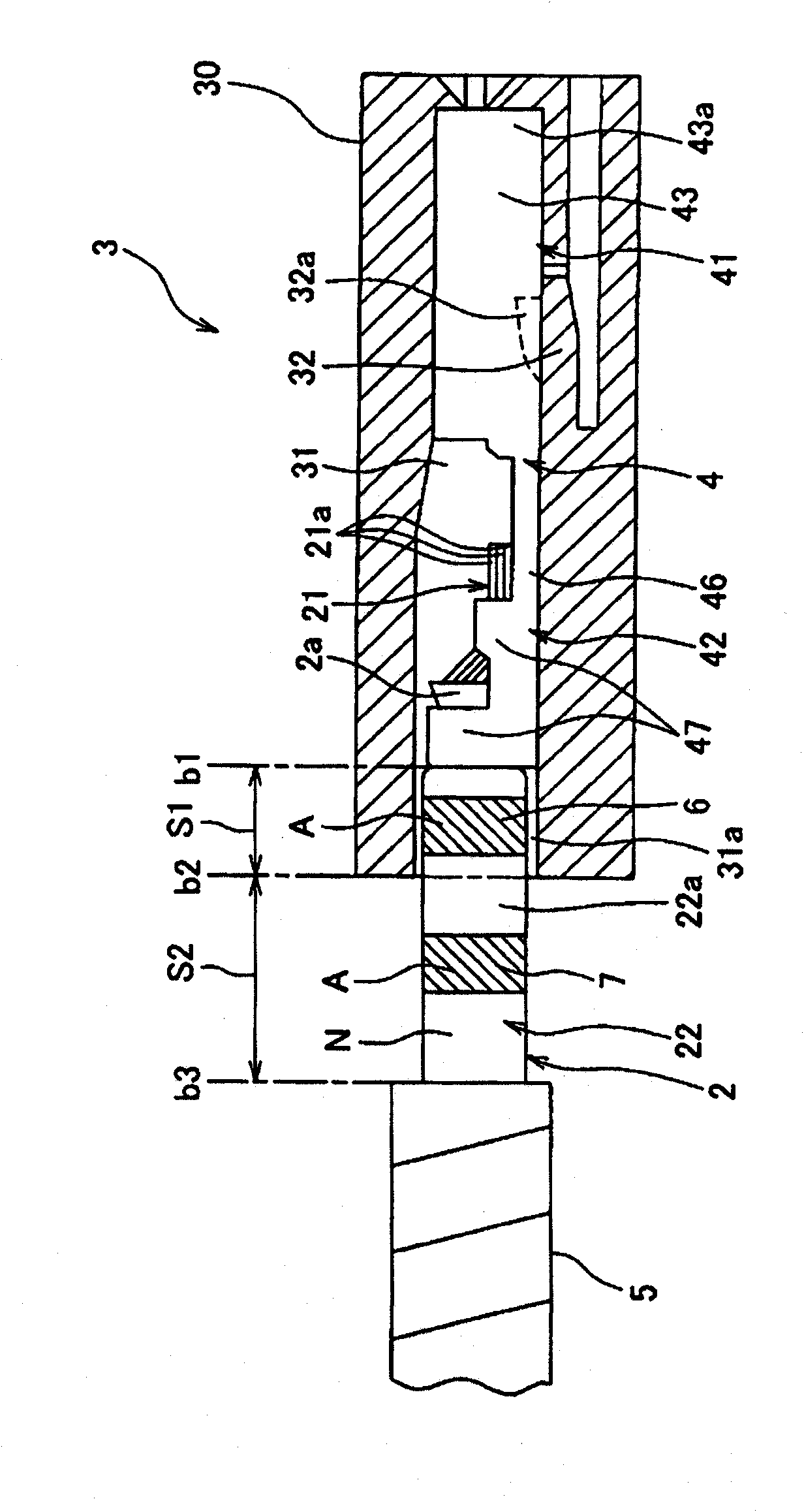

[0019] Below, refer to Figure 1 to Figure 3 A wire harness according to one embodiment of the present invention will be described. The wire harness 1 according to one embodiment of the present invention is mounted on, for example, an automobile which is a mobile body. Such as figure 1 As shown, the wire harness 1 has an electric wire 2, a connector 3, an exterior tape 5 as an exterior part, a first mark 6 ( image 3 ) and the second notation 7.

[0020] A plurality of electric wires 2 (two in the illustrated example) are provided. The electric wire 2 is a so-called covered electric wire 2 and is, for example, a low-voltage electric wire used for a low-voltage circuit in a motor vehicle. Such as image 3 As shown, the electric wire 2 has a conductive core wire 21 and an insulating covering portion 22 . The core wire 21 is formed by twisting a plurality of monofilaments 21a. The monofilament 21a constituting the core wire 21 is made of a conductive metal such as copper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com