Piston type titanium wire mesh cage and manufacturing method thereof

A titanium, piston-type technology, used in medical science, prosthesis, spinal implants, etc., can solve the problem of inability to use bone grafting effect of micro-particle bone and titanium wire engineered bone, increase the time of crawling replacement, and reduce implantation. Bone healing effect and other issues, to achieve the effect of expanding the range of bone graft particle size, promoting active implantation, and improving the effect of bone graft healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

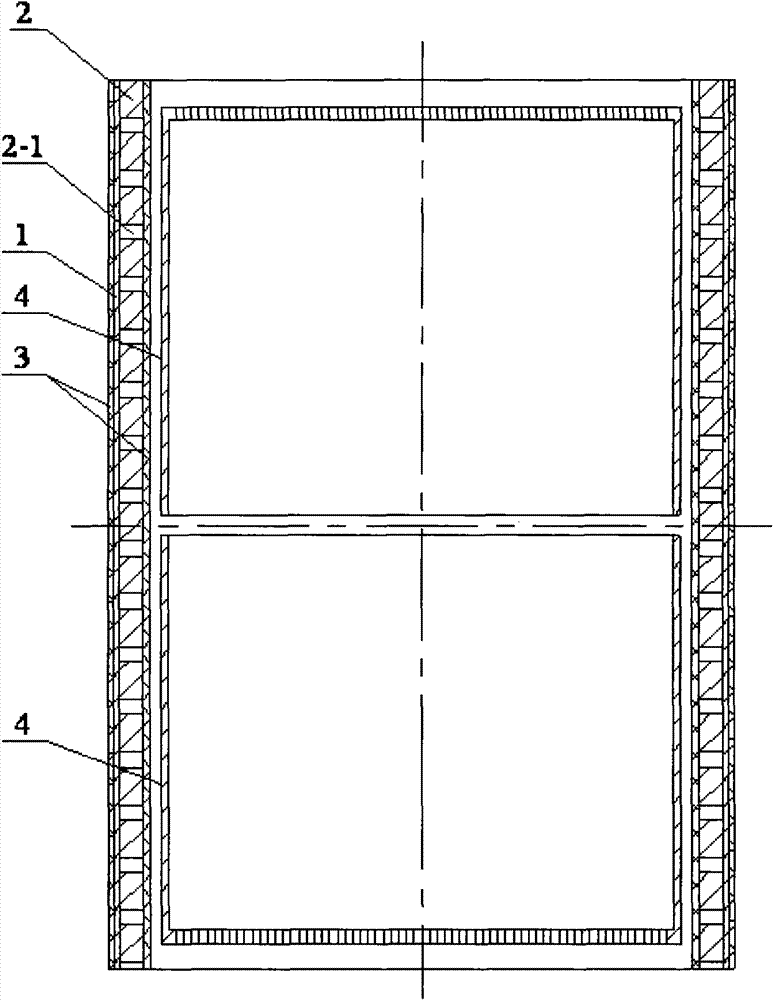

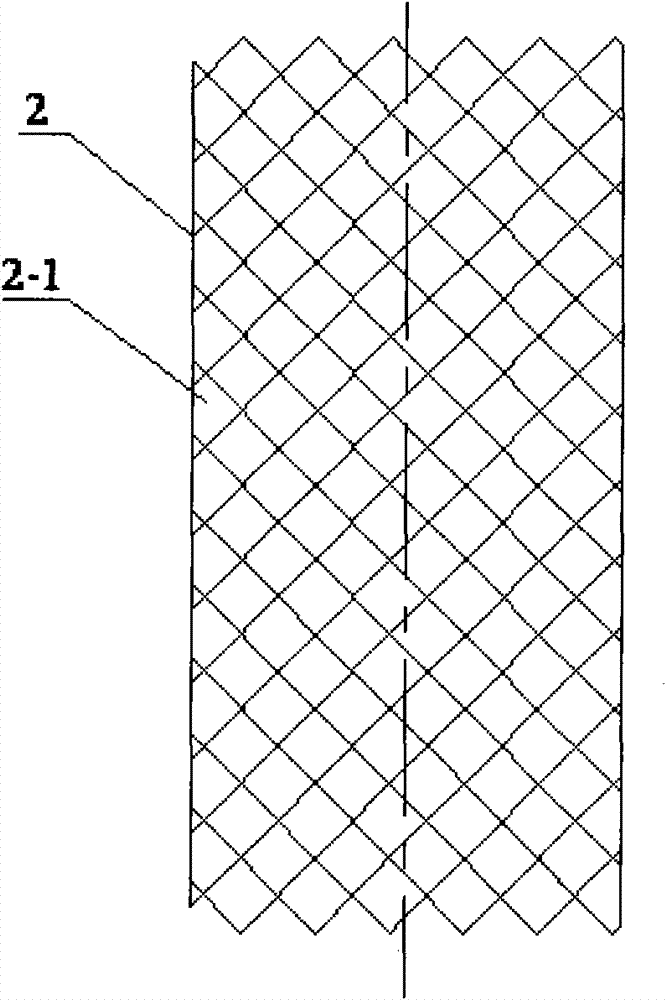

[0034] Embodiment 2: The outer wall of the titanium metal cage 2 in this embodiment is wound with two to three layers of titanium wire non-woven fabric or titanium wire woven cloth 1 . It can ensure that the filled tiny granular bone will not fall out of the first through hole 2-1 of the titanium metal cage body 2, and ensure better growth of new bone tissue. Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment three: the titanium metal wire in the titanium metal wire non-woven fabric of the present embodiment or the titanium metal wire woven cloth 1 is metal titanium and its alloy metal wire, and in the titanium metal wire non-woven fabric or the titanium metal wire woven cloth 1 The diameter of the titanium wire is 10-120 μm. Such setting can improve the bonding force between the titanium metal wire and the bone cell tissue. Others are the same as the first embodiment.

specific Embodiment approach 4

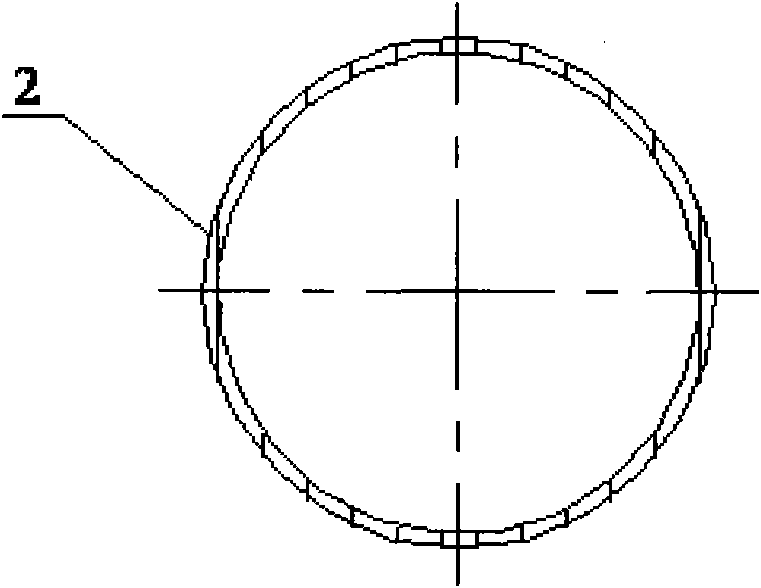

[0036] Specific implementation mode four: see image 3 To illustrate, the wall thickness of the titanium metal cage 2 in this embodiment is 1-3mm. Such setting can ensure that the titanium metal cage body 2 has sufficient strength. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com