Ballast liquid preparation and delivery pry block

A skid block and carrier liquid technology, applied in mixer accessories, dissolving, mixer and other directions, can solve the problems of limited number of offshore operators, long mixing and mixing time, restricting the normal production of oil fields, etc., saving manpower and improving work. Efficiency and effect of shortening work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

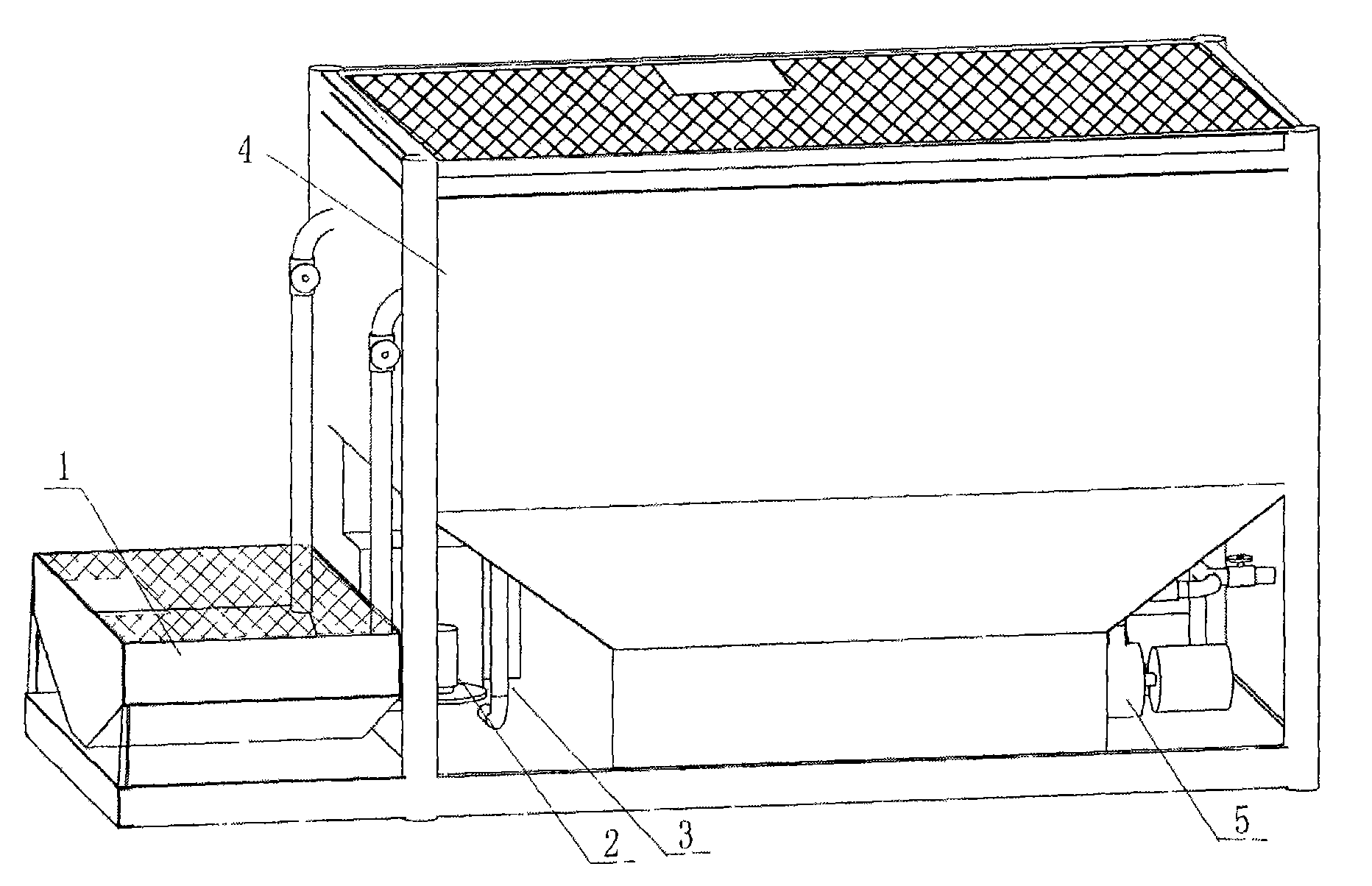

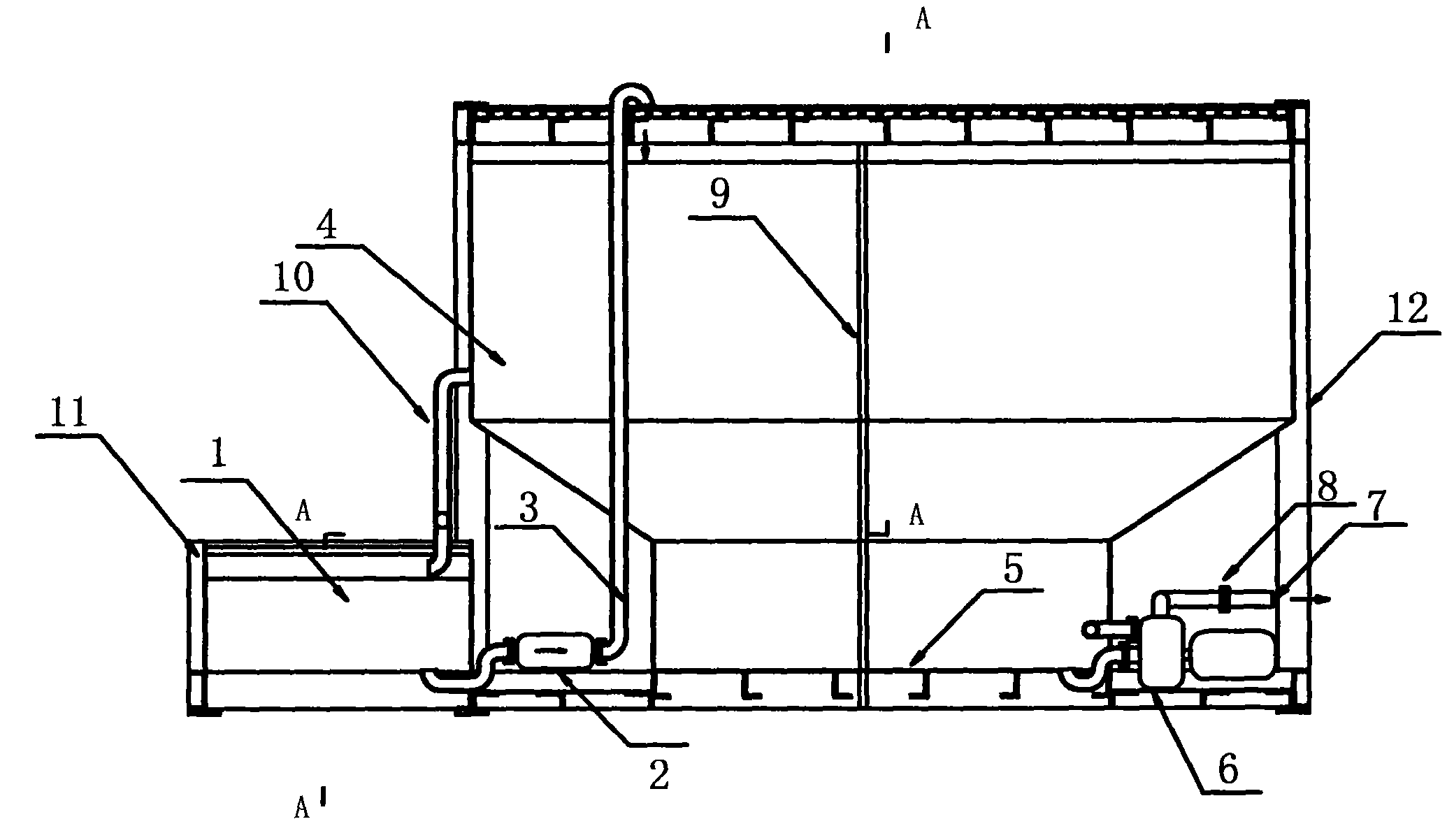

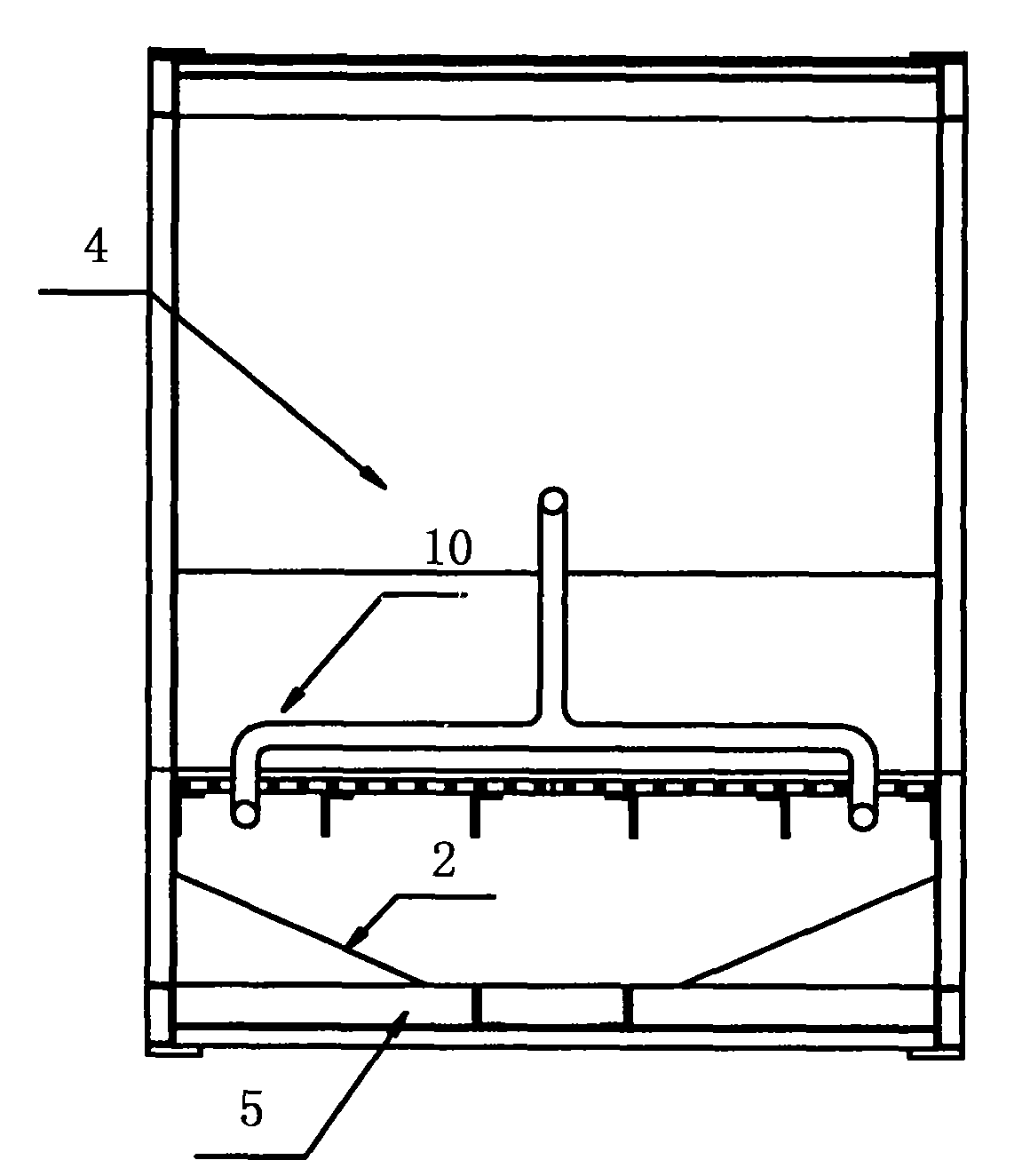

[0021] Such as figure 1 —— Figure 4 As shown, the present invention includes: a stirrer 5 installed at the bottom of the mixing tank 4 for mixing and stirring the antifreeze particles and water. A feeding tank 1 is installed on one side of the mixing tank 4, and the bottom of the feeding tank 1 is respectively connected to one end of two feeding pipeline pumps 2 through a pipeline, and the other end of the pipeline pump 2 is connected to a feeding pipeline, and the feeding pipeline is installed In the inlet of the mixing tank 4, the added raw materials are pumped into the mixing tank through the feeding pipeline pump 2. Two return pipes 10 are installed in the middle of the mixing tank 4, and the other end of the return pipe 10 is installed on the top of the feeding tank 1. A control valve is installed on the return pipe 10, and the liquid in the mixing tank 4 is returned by opening the control valve. In the upper feed tank 1, it is fully dissolved. Then, the mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com