Current-assisted fuel cell ultra-thin metal bipolar plate pressure welding device and method

A fuel cell and ultra-thin metal technology, applied in resistance welding equipment, metal processing equipment, welding power supply, etc., can solve problems such as complex process, low efficiency, and difficult control of solder coating uniformity, and achieve large radiation energy scattering, Low efficiency, good connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

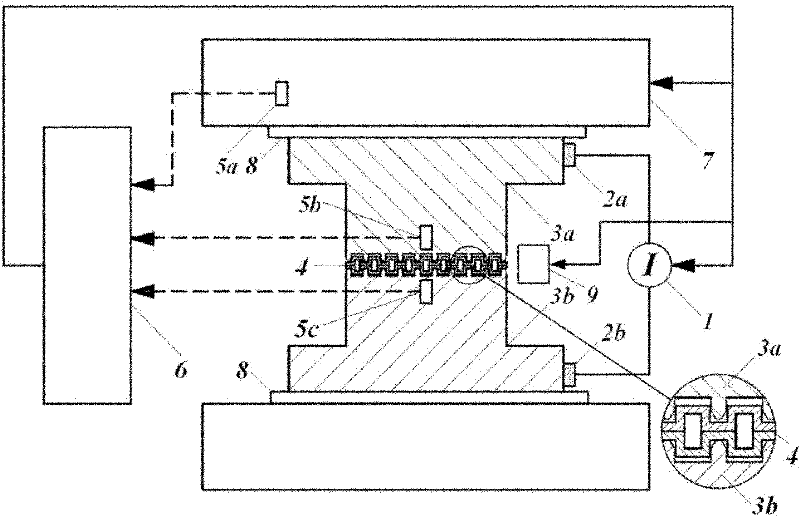

[0029] Such as figure 1 As shown, this embodiment includes: a power supply 1, a first electrode 2a, a second electrode 2b, an upper welding head 3a, a lower welding head 3b, a bipolar plate 4, a first sensor 5a, a second sensor 5b, and a third sensor 5c , Controller, actuator 7, insulation layer 8 and cooling system 9. In this embodiment, the power source 1 is connected to the first electrode 2a and the second electrode 2b, the first electrode 2a is connected to the upper welding head 3a, and the second electrode 2b is connected to the lower welding head 3b, thereby forming a circuit. The second sensor 5b and the third sensor 5c respectively collect the temperature of the upper and lower surfaces close to the connection area, the first sensor 5a collects the pressure information of the actuator 7, and the first, second and third sensors all transmit data to the controller 6 . The controller 6 generates control signals to control the current of the power supply 1 and the pres...

Embodiment 2

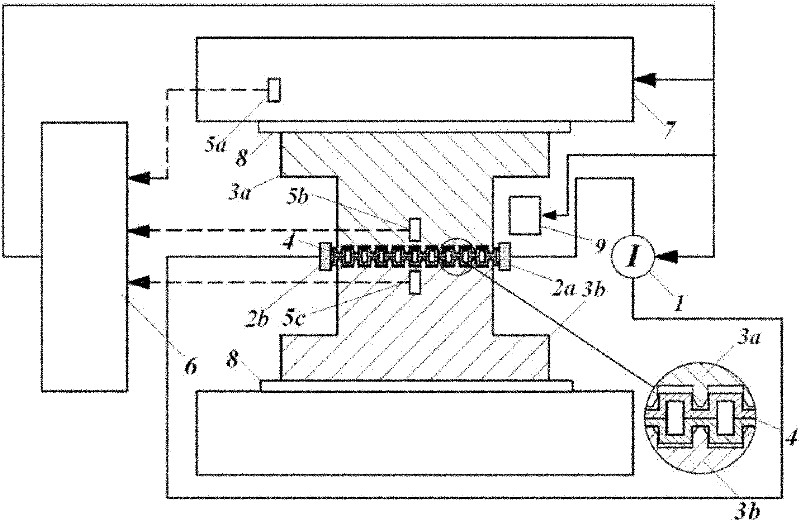

[0041] Such as figure 2 As shown, this embodiment includes: a power supply 1, a first electrode 2a, a second electrode 2b, an upper welding head 3a, a lower welding head 3b, a bipolar plate 4, a first sensor 5a, a second sensor 5b, and a third sensor 5c , controller 6, actuator 7, insulation layer 8 and cooling system 9. In this embodiment, the power supply 1 is connected to the first electrode 2a and the second electrode 2b, the first electrode 2a is connected to one side of the bipolar plate, and the second electrode 2b is connected to the other side of the bipolar plate, so that the entire bipolar plate can pass current. The second sensor 5b and the third sensor 5c respectively collect the temperature near the upper and lower surfaces of the welding area, the first sensor 5a collects the pressure information of the actuator 7, and the first, second and third sensors all transmit data to the controller 6 . The controller 6 generates control signals to control the current...

Embodiment 3

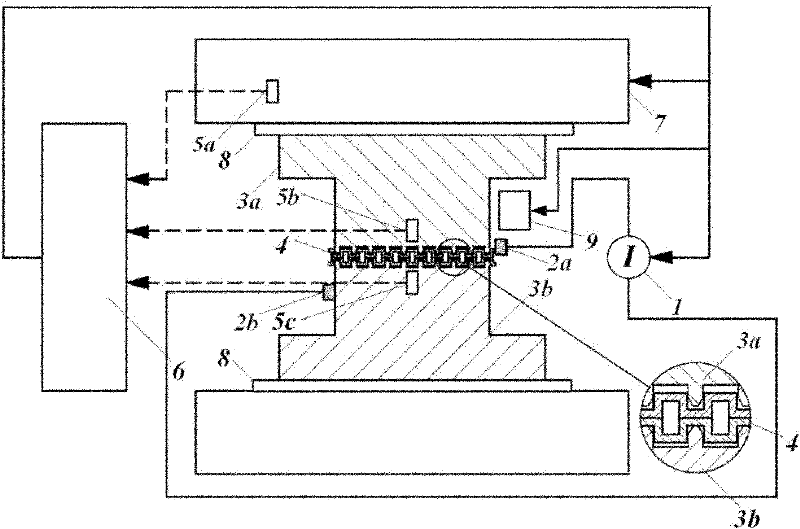

[0053] Such as image 3 As shown, this embodiment includes: a power supply 1, a first electrode 2a, a second electrode 2b, an upper welding head 3a, a lower welding head 3b, a bipolar plate 4, a first sensor 5a, a second sensor 5b, and a third sensor 5c , controller 6, actuator 7, insulation layer 8 and cooling system 9. In this embodiment, the power source 1 is connected to the first electrode 2a and the second electrode 2b, the first electrode 2a is connected to the upper unipolar plate, and the second electrode 2b is connected to the lower welding head to form a circuit. The second sensor 5b and the third sensor 5c respectively collect the temperature near the upper and lower surfaces of the welding area, the first sensor 5a collects the pressure information of the actuator 7, and the first, second and third sensors all transmit data to the controller 6 . The controller 6 generates control signals to control the current of the power supply 1 and the pressure and displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com