Sensor for monitoring tearing of coal conveyer belt

A sensor and belt technology, applied in the field of belt longitudinal tear monitoring, can solve the problems of inconvenient installation and operation, poor anti-interference ability, and low detection accuracy, and achieve the effects of convenient processing and production, strong anti-interference ability, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

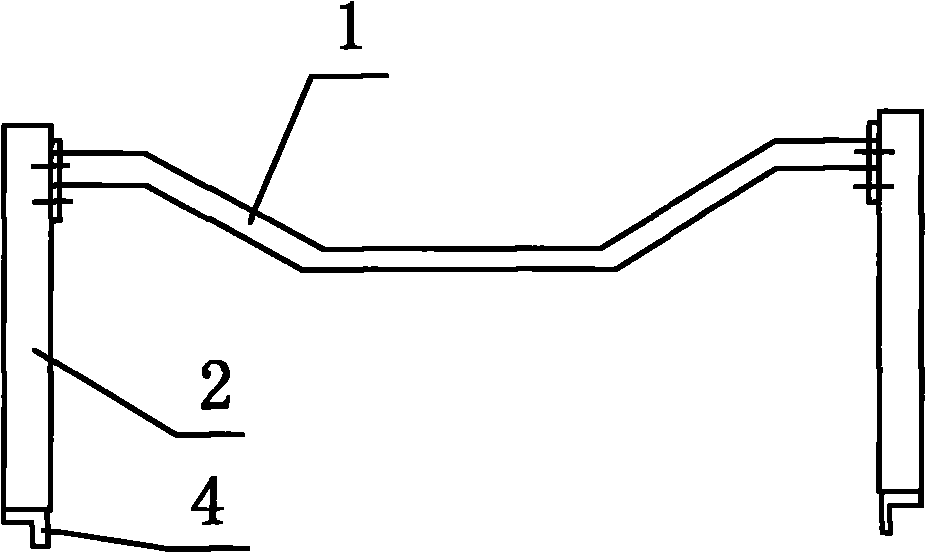

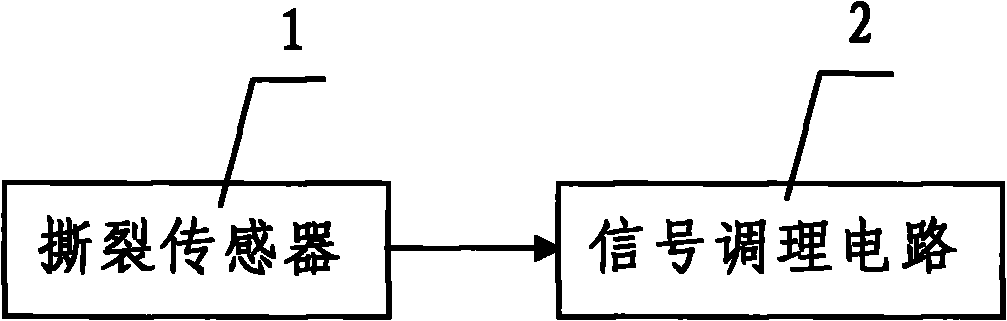

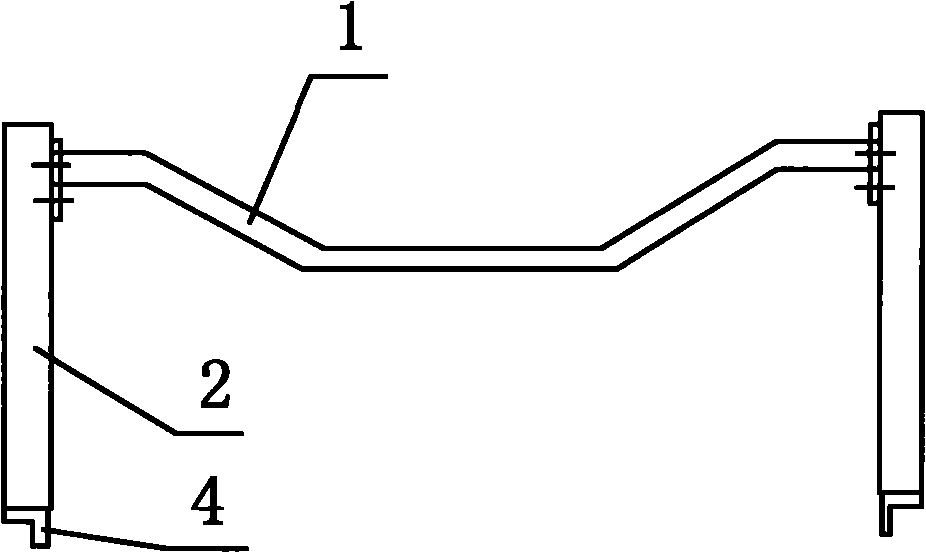

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a bow-shaped tear sensor 1 installed on the frame below the coal conveyor belt, and also includes a signal conditioning circuit 2 connected to the tear sensor 1 and two symmetrically installed on the left and right sides of the tear sensor 1. The brackets 3, the bottoms of the two brackets 3 are respectively provided with connectors 4 connected to the frame, and the connectors 4 and the frame are connected by welding. The tear sensor 1 is a conductive rubber tear sensor. The tear sensor 1 and the bracket 3 are connected by bolts.

[0020] In this embodiment, the bracket 3 is a vertical support rod made of angle steel. The signal conditioning circuit 2 is an integrated circuit for amplifying, filtering and anti-interference processing on the signal detected by the tear sensor 1 .

[0021] When the belt on the belt conveyor is working normally, the tear sensor 1 is in a state of high resistance (DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com