Mine dedusting system and method

A dust removal system and mine technology, applied in dust prevention, mining equipment, earthwork drilling and mining, etc., can solve the problems that affect the dust removal effect, fail to improve, endanger the physical and mental health of coal mine safety production workers, etc., and achieve improved contact characteristics, Effect of improving dust removal efficiency and ensuring strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the invention will be further described below in conjunction with the accompanying drawings:

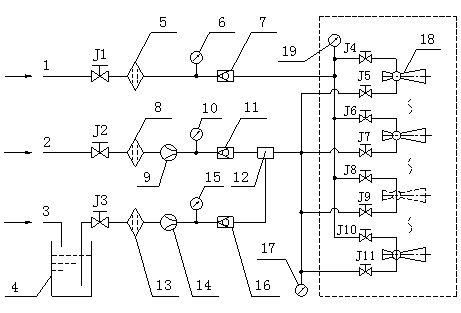

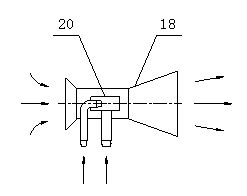

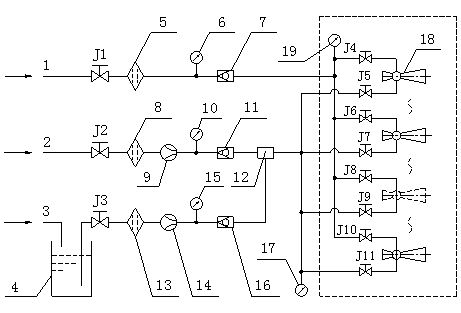

[0024] Such as figure 1 As shown, the mine dust removal system of the present invention is mainly composed of a spray device, a pressure air adjustment supply pipeline 1, a water pressure adjustment supply pipeline 2 and a dust removal agent quantitative addition pipeline 3. The pressure adjustment supply pipeline 1, The feed water pressure adjustment supply pipe 2 is connected in parallel to the spray device, the dust removal agent quantitative addition pipe 3 is connected in series to the water pressure adjustment supply pipe 2, and the air pressure adjustment supply pipe 1 is sequentially provided with a pressure air regulator Valve J1, compressed air filter 5, air pressure gauge 6 and compressed air check valve 7; the feed water pressure regulating supply pipeline 2 is sequentially provided with a feed water regulating valve J2, a feed water filter 8, and an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com