Automatic measuring instrument for parameter of thermoelectric material

A technology of thermoelectric materials and measuring instruments, which is applied in the field of measuring instruments, can solve problems such as difficulties in measuring thermal conductivity k, difficulty in simultaneously measuring thermoelectric materials, affecting performance characterization and application research of thermoelectric materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

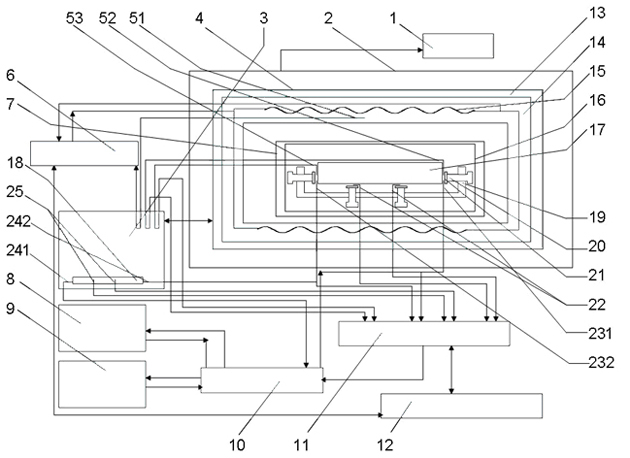

[0022] The principle structure of the present invention is as figure 1 shown.

[0023] When measuring the parameters of thermoelectric materials, select the thermal conductivity k at a certain temperature SD Known thermoelectric materials whose performance is similar to that of the sample to be tested are made into a standard sample with the same size as the sample to be tested. After the precision DC constant current power supply 9 is powered off for a period of time, the temperature difference between the two ends of the sample 17 tends to change linearly, and the rate of change of the temperature difference (d T / d t ) is proportional to the thermal conductivity k of sample 17, k= k *(d T / d t ), where the proportionality factor k From the rate of change of the temperature difference of the standard sample (d T / d t ) SD =k SD / k inferred.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com