Liquid mechanical loss analysis meter and control method thereof

A mechanical loss and analyzer technology, applied in the field of measuring instruments, can solve the problems of large motor inertia, unsuitable for loading and measuring low-viscosity liquid, and large liquid volume, so as to reduce inertia, automatically measure liquid mechanical loss, and improve test accuracy. Effect

Inactive Publication Date: 2013-06-19

SUN YAT SEN UNIV

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the dynamic rheometer, the shear wave generated by the liquid sample decays quickly during dynamic measurement, and the motor with an air bearing has a large inertia, which makes the stress and strain of the liquid sample (especially low-viscosity liquid) difficult to be accurate. Measurement

The component modes of dynamic rheometer cone-plate / plate and plate / plate are not suitable for loading and measuring low-viscosity liquids. Although the concentric cylinder type can measure the parameters of low-viscosity liquids more accurately, the amount of liquid that needs to be loaded is relatively large. Big

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

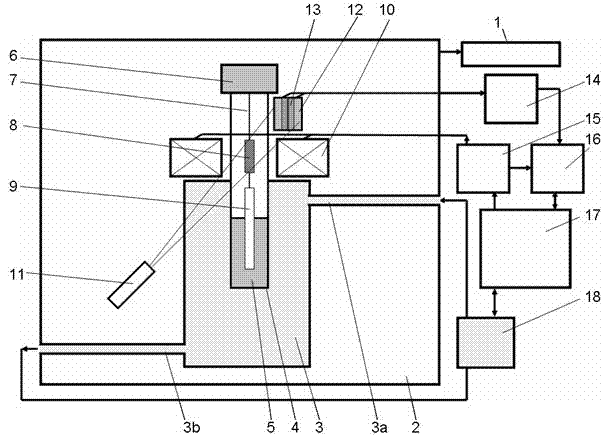

[0033] like figure 1 As shown, it is a schematic structural diagram of a liquid mechanical loss analyzer according to an embodiment of the present invention, including a vacuum test system and a control system. The vacuum test system includes a test assembly and a vacuum cover 2 for accommodating the test assembly; the vacuum cover 2 is connected with a mechanical pump 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of measuring instruments, in particular to a liquid mechanical loss analysis meter and a control method of the liquid mechanical loss analysis meter. The liquid mechanical loss analysis meter comprises a vacuum testing system and a control system. The vacuum testing system comprises a mechanical pump, a vacuum cover, a circulation oil bath, a test sample tube, a fixing mechanism, an oscillation starting sheet, a permanent magnet, a sheet, an electromagnetic drive coil, a laser source, and a differential photocell. A computer control system comprises an amplifying circuit, a signal generator, an analog / digital converter, a computer system and a circulation oil bath temperature controller. The device can automatically measure mechanical loss of liquid in each temperature point and improve measuring precision.

Description

technical field [0001] The invention relates to the technical field of measuring instruments, in particular to a liquid mechanical loss analyzer and a control method thereof. Background technique [0002] The change of phase or properties of liquid is usually accompanied by the change of viscoelasticity, so the characterization of liquid viscoelasticity is of great significance to the study of liquid. [0003] At present, the main instrument used to characterize the viscoelastic properties of liquids is the rheometer, which mainly includes three types: capillary rheometer, torque rheometer and dynamic rheometer. Using a capillary rheometer or a torque rheometer, the material is passed through the instrument to obtain liquid viscosity and melt flow data, but these two rheometers have poor measurement accuracy and are not suitable for low viscosity liquids. sample, it is more difficult to measure accurately. The working principle of the dynamic rotary or oscillating rheomete...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N19/00

Inventor 林国淙刘晖丁喜冬

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com