Failure analysis expert system based member failure mode detection method

An expert system and failure analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as easy loss, low work efficiency, effective storage and full utilization of unfavorable knowledge, and achieve the goal of avoiding human factors Effects of interference, improving the accuracy of analysis, and making up for the lack of personal knowledge and experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

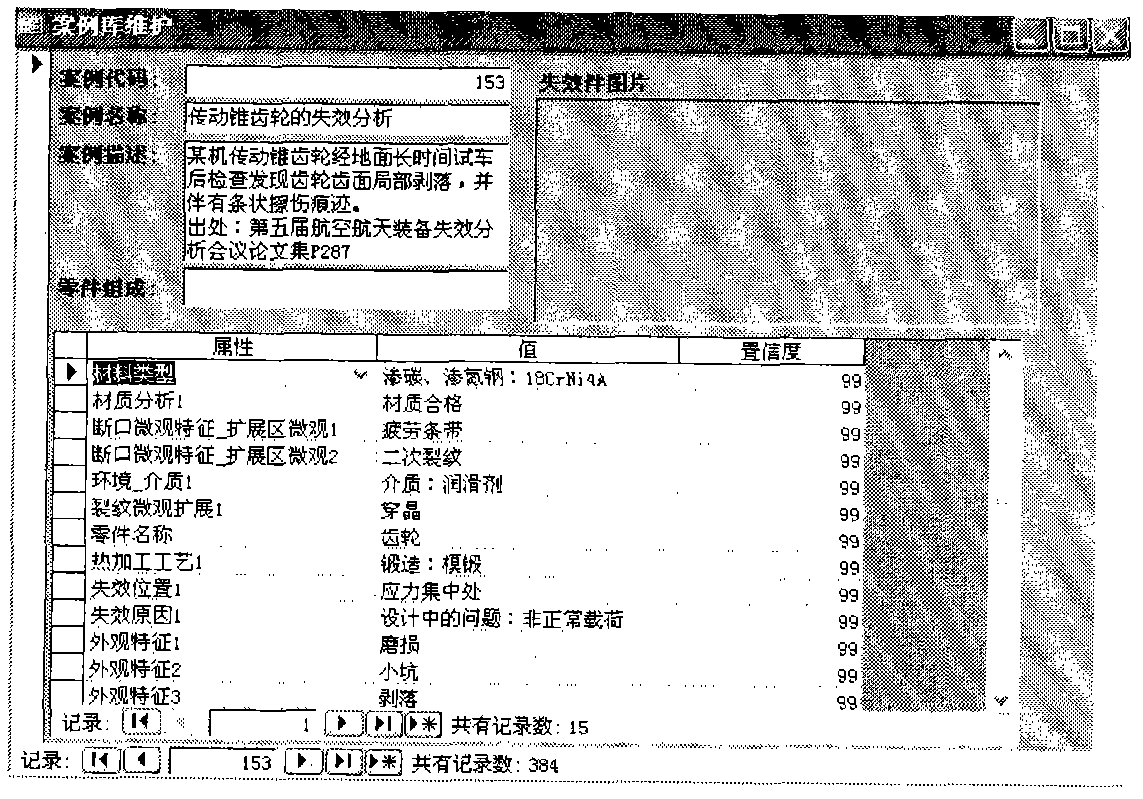

[0041] After a long test run on the ground, the transmission bevel gear found that the tooth surface of the gear was partially peeled off, accompanied by strip scratches. It is necessary to judge the failure mode of the detected gear. Firstly, the failure analysis of the gear was investigated, observed and tested, and the results are as follows:

[0042] Part name: gear

[0043] Material type: 18CrNi4A carburized and nitrided steel

[0044] Material analysis result: the material is qualified

[0045] Load Type: Contact Fatigue Load

[0046] Crack microscopic growth: transgranular

[0047] Failure location: stress concentration

[0048] Thermal processing technology: die forging

[0049] Microscopic view of fracture growth zone: fatigue bands, secondary cracks

[0050] Environment - Media: Lubricant

[0051] Appearance features: peeling, small pits, wear

[0052] Before using the expert system to detect the failure mode, the observation and measurement information of th...

Embodiment 2

[0055] Austenitic stainless steel springs need to determine their failure mode. First, investigate, observe and test the failure information of the spring, the results are as follows:

[0056] Part Name: Spring

[0057] Material Type: Austenitic Stainless Steel

[0058] Material analysis result: the material is qualified

[0059] Failure location: Defect area caused by corrosion

[0060] Observation results of macroscopic characteristics of cross-section: fatigue arc

[0061] Observation results of microscopic characteristics of the fracture: the expansion zone is fatigue strips and mud patterns, and the instantaneous fracture zone is dimples

[0062] Environment-medium: corrosive medium

[0063] Appearance features: fractures, corrosion pits

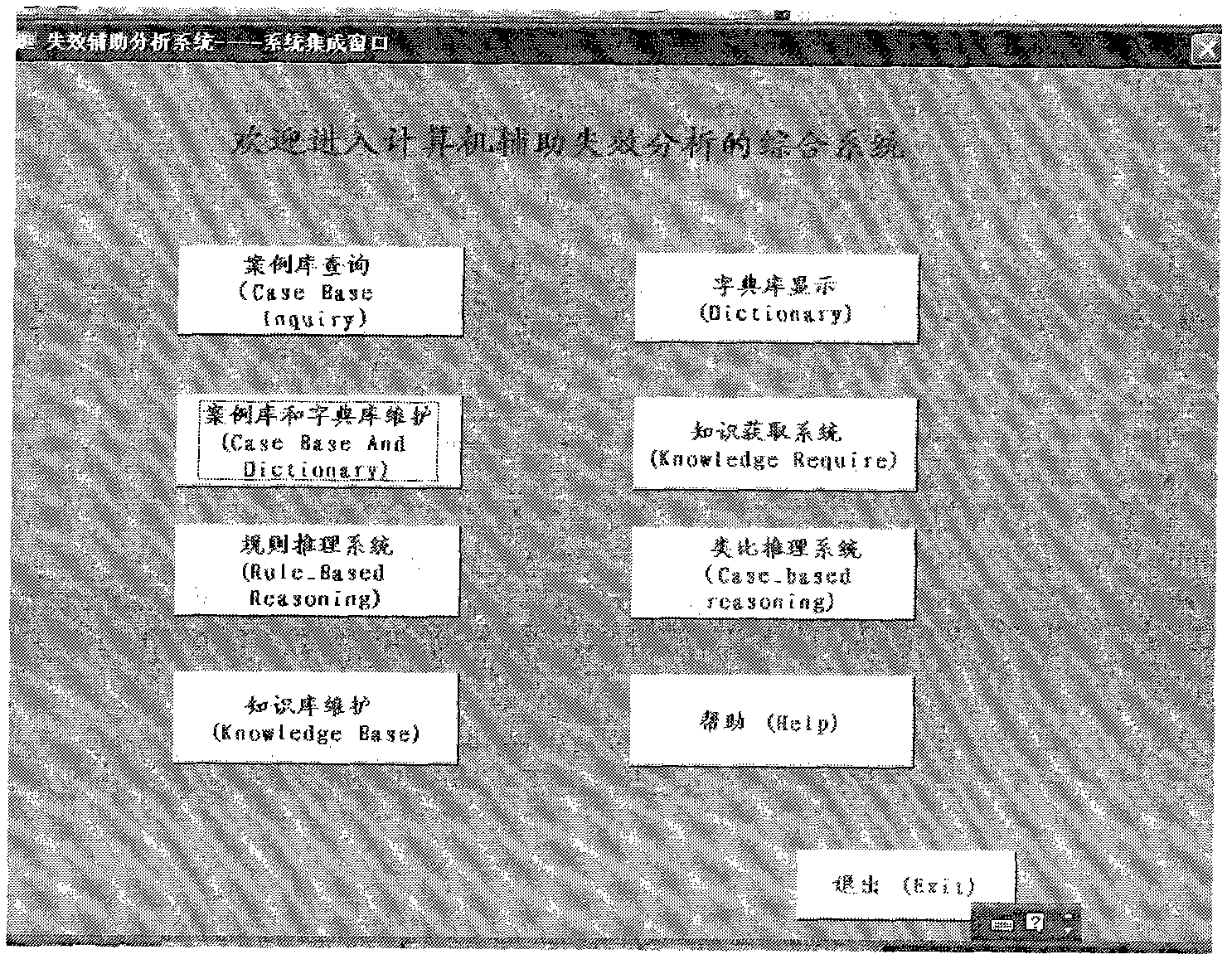

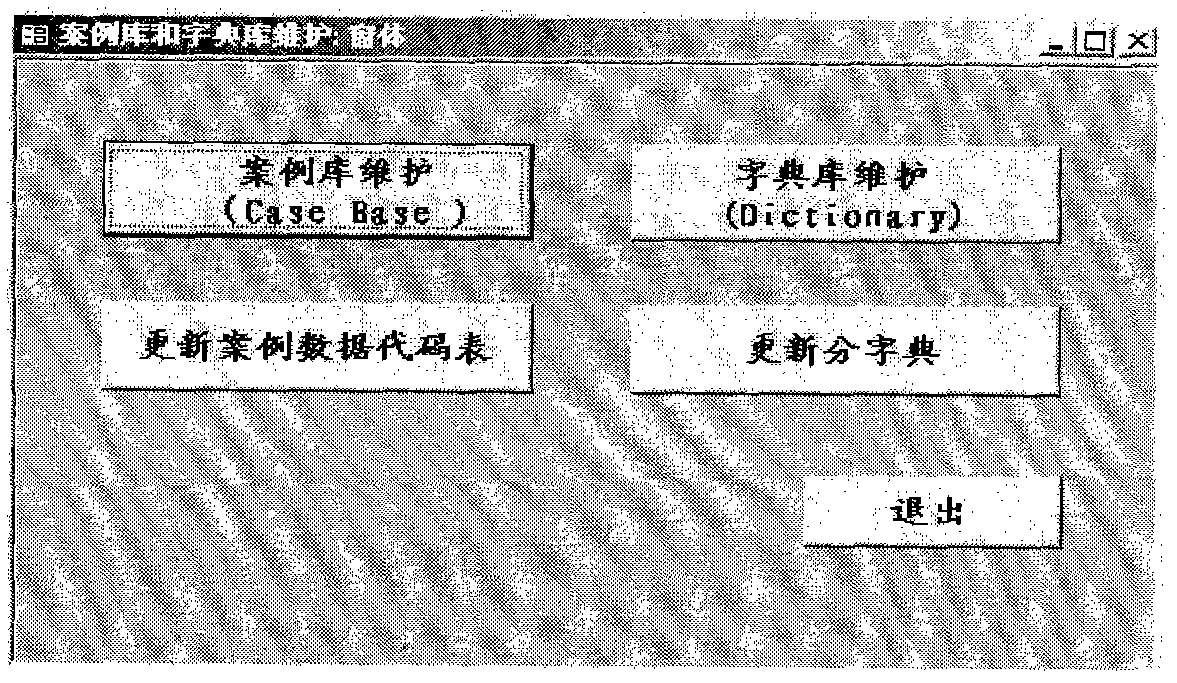

[0064] Using the same method as case 1, input the failure information of this case into the failure analysis expert system, and randomly give the case code 263. click figure 1 Click the "Analogical Reasoning System" button in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com