NiMnZn ferrite material and preparation method thereof

A ferrite material and raw material technology, applied in the direction of inorganic material magnetism, can solve the problem of loss reduction, achieve the effect of reducing volume, realizing light and thin, and realizing energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

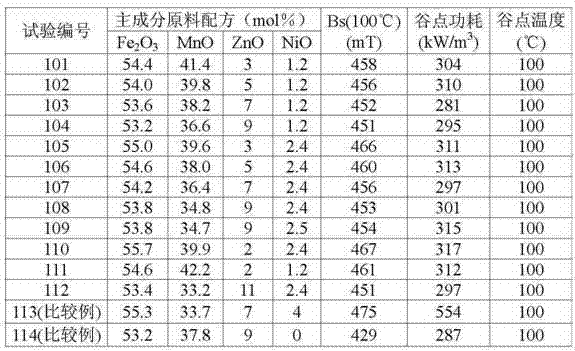

Embodiment 1

[0033]Take by weighing Fe with the main component raw material formula shown in Table 1 2 o 3 , MnO, ZnO, and NiO raw materials were wet mixed, and then pre-fired at 900 ° C for 2 hours. Based on the total weight of the main component raw materials, add 150ppm of SiO to the pre-fired mixture 2 , 900ppm of CaCO 3 , 200ppm ZrO 2 , 200ppm Nb 2 o 5 and 100ppm Na 2 O, where Na 2 O was added in the form of NaCl, and wet sanding treatment was performed to obtain ferrite slurry. Add 1wt% PVA binder calculated by ferrite powder weight to the slurry for spray granulation. at 1 ton / cm 2 Under high pressure, the granulated powder is molded into a standard ring ferrite core for testing. Then the molded body was sintered at 1300°C for 5 hours under the condition of controlled oxygen partial pressure, wherein the heating rate was 4°C / min during the heating stage from 1000°C to 1300°C, and the oxygen partial pressure concentration was 0.1%. Then in balance O 2 -N 2 cooling in an ...

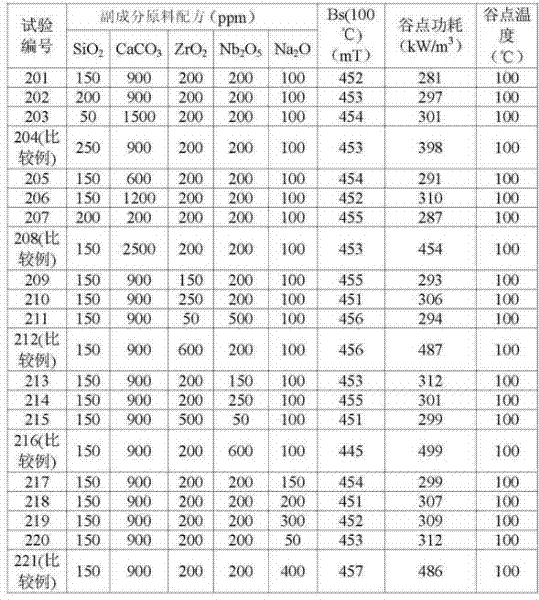

Embodiment 2

[0039] The preparation process of the magnetic core is the same as that of Example 1. The difference is that the formula of the main component raw material is fixed at 53.6mol% Fe 2 o 3 , the MnO of 38.2mol%, the ZnO of 7mol% and the NiO of 1.2mol%; 2 O to Na 2 CO 3 form to join.

[0040] Table 2

[0041]

[0042] As can be seen from Table 2, when the add-on of secondary component raw materials is within the scope of the present invention, the volume power consumption of the magnetic core is low; when the add-on of secondary component raw materials deviates from the scope of the present invention, the volume power consumption of the magnetic core has a tendency to deteriorate.

Embodiment 3

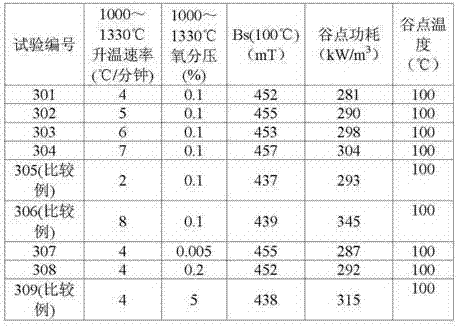

[0044] The composition of the magnetic core is the same as the test number 103#. The preparation process is the same as that of Example 1, except that the heating rate and oxygen partial pressure concentration in the heating section of 1000° C. to 1330° C. are shown in Table 3.

[0045] table 3

[0046]

[0047] It can be seen from Table 3 that when the heating rate is lower than 4°C / min, the high-temperature saturation magnetic flux density of the magnetic core decreases; when the heating rate is higher than 7°C / min, the high-temperature saturation magnetic flux density of the magnetic core decreases and the power consumption increases. High; when the oxygen partial pressure concentration is higher than 0.2%, the high temperature saturation magnetic flux density of the magnetic core decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com