Anti-bouncer for circuit breaker

An anti-bounce and circuit breaker technology, applied in circuits, contacts, electrical components, etc., can solve the problems of device failure, large electric repulsion, and small electric repulsion, and achieve the effects of simple structure, reliable performance and long mechanical life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

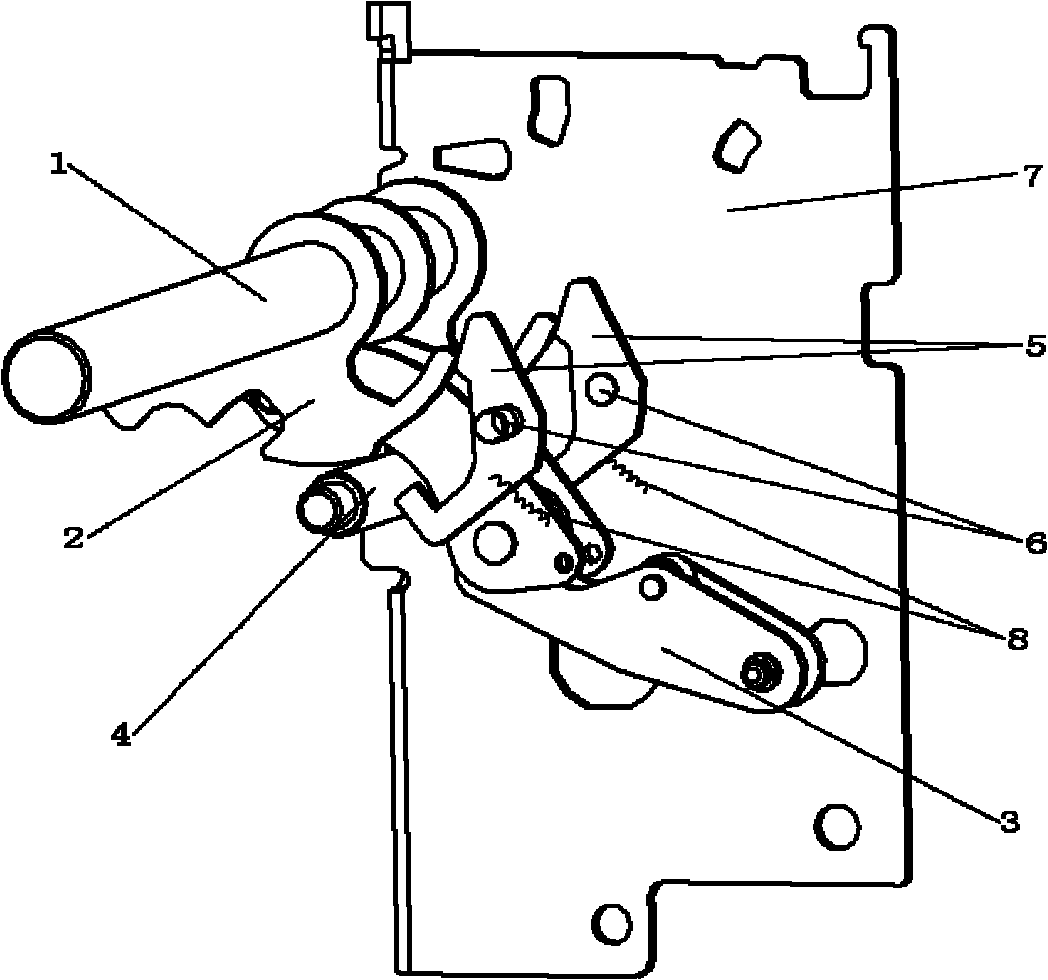

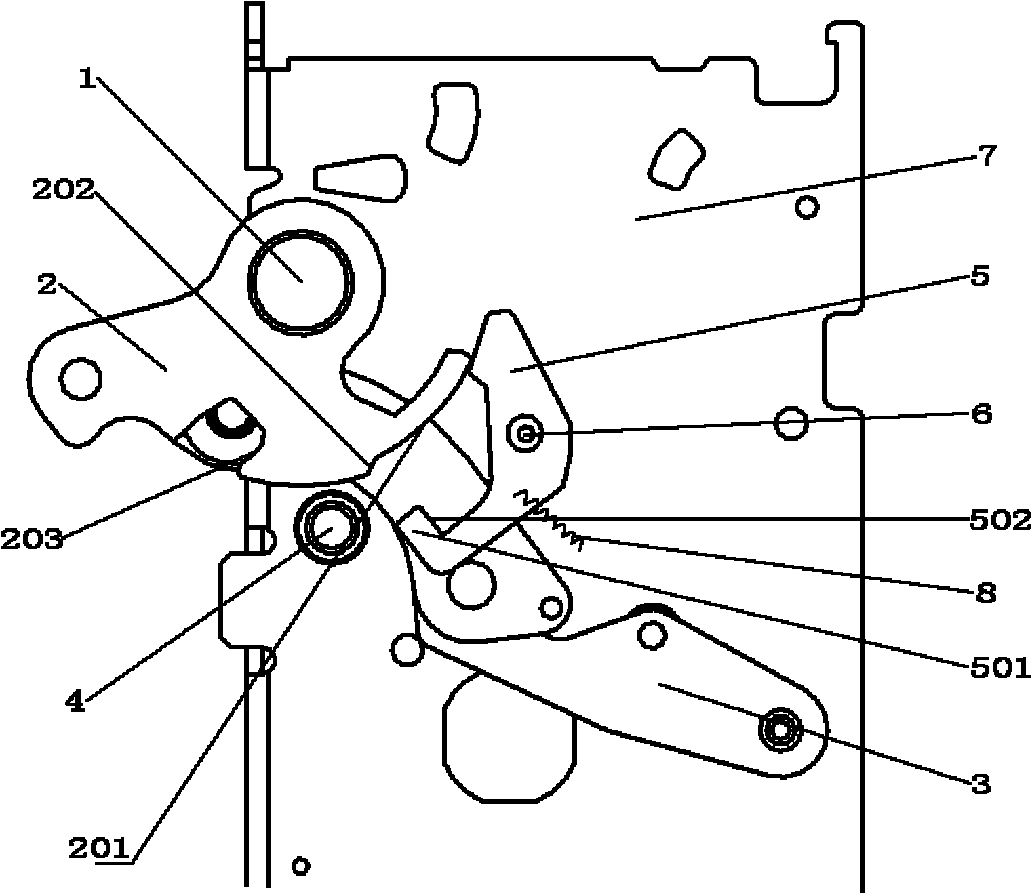

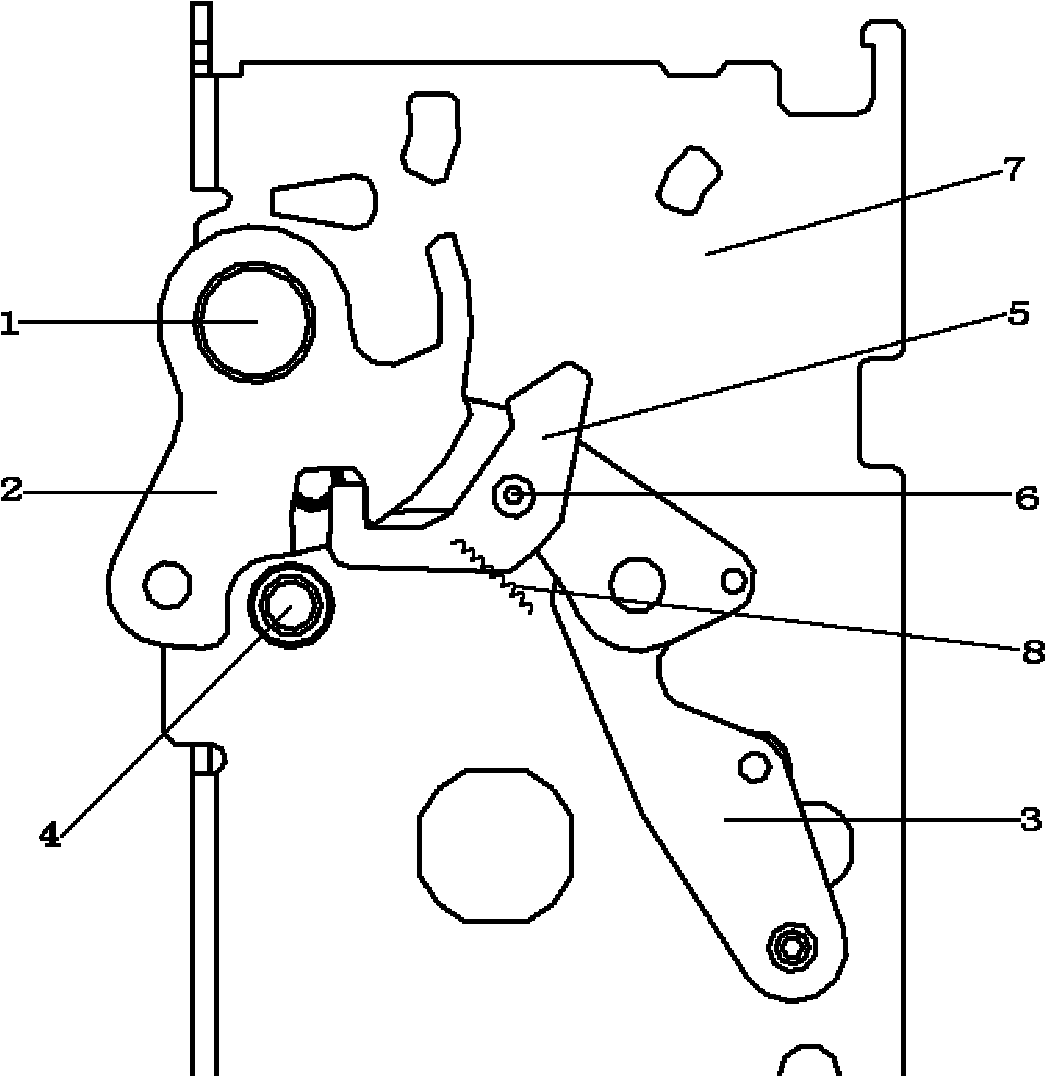

[0017] refer to figure 1 , 2 , 3, and 4, the present invention includes a main shaft 1, a transmission member 2, a connecting rod system 3, a stopper 4, a hook rod 5, a shaft pin 6, a side plate 7, and a return spring 8; the side plate 7 is The side plate of the circuit breaker mechanism is fixed on the circuit breaker frame, the main shaft 1 passes through the hole on the side plate 7 and can rotate around the hole on the side plate 7; the transmission part 2 and the main shaft 1 are fixed and rotate with the main shaft 1, and the transmission part 2. The left side is connected with the moving contact system of the circuit breaker; the stopper 4 passes through the hole on the side plate 7 and is fixed on the side plate 7 by riveting, and its function is to limit the rotation of the main shaft 1 and the transmission part 2; the connecting rod system 3 Connected with the main shaft 1 to drive the circuit breaker to open and close; the shaft pin 6 is fixed on the side plate 7 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com