Manufacture method of photovoltaic component device

A photovoltaic element and manufacturing method technology, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of unloadable output current, short circuit of photovoltaic element devices, etc., and achieve the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In order to enable your examiner to have a further understanding and understanding of the characteristics, purpose and functions of the present invention, the relevant detailed structure and design concept of the present invention will be explained below, so that the examiner can understand the characteristics of the present invention , the detailed statement is as follows:

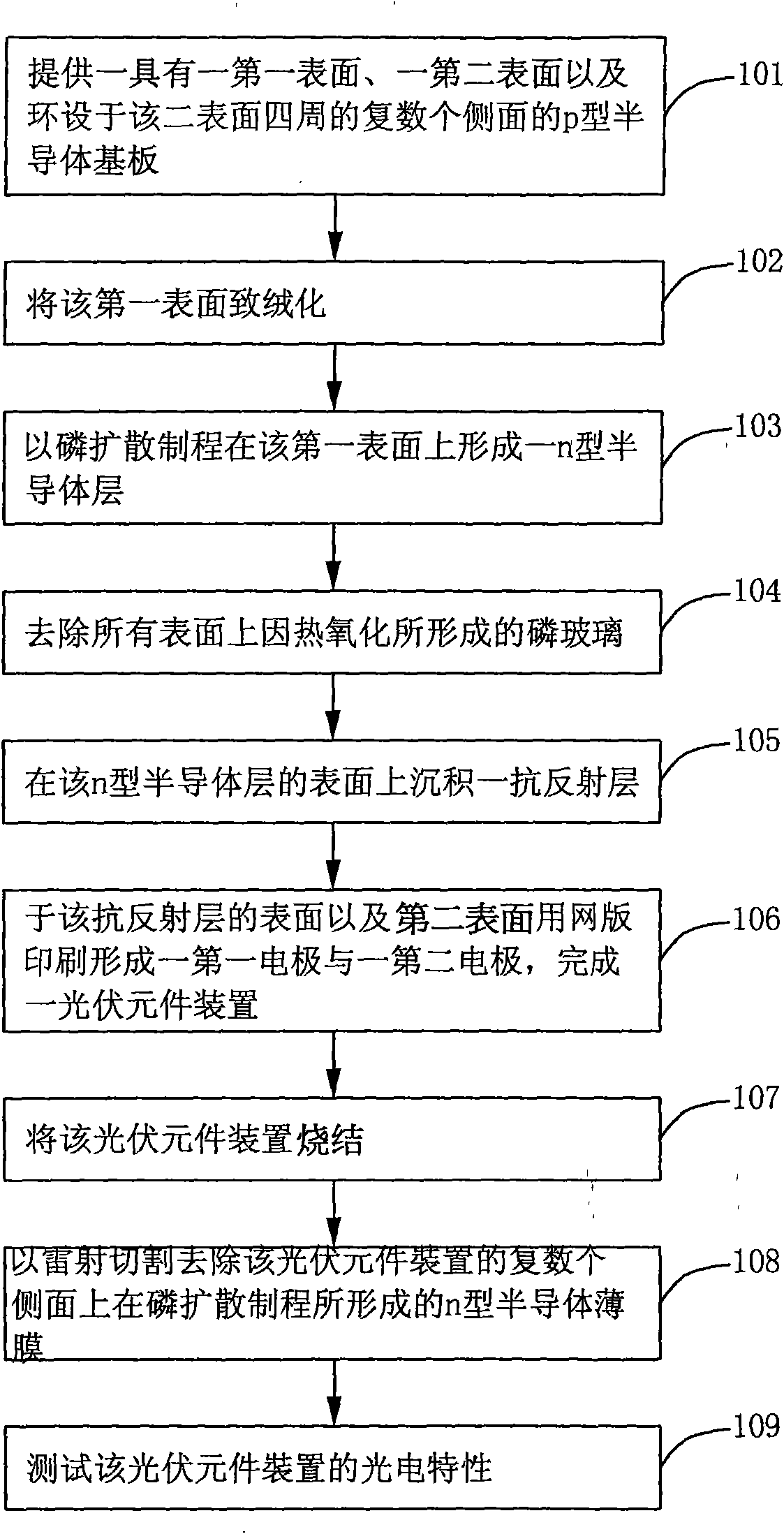

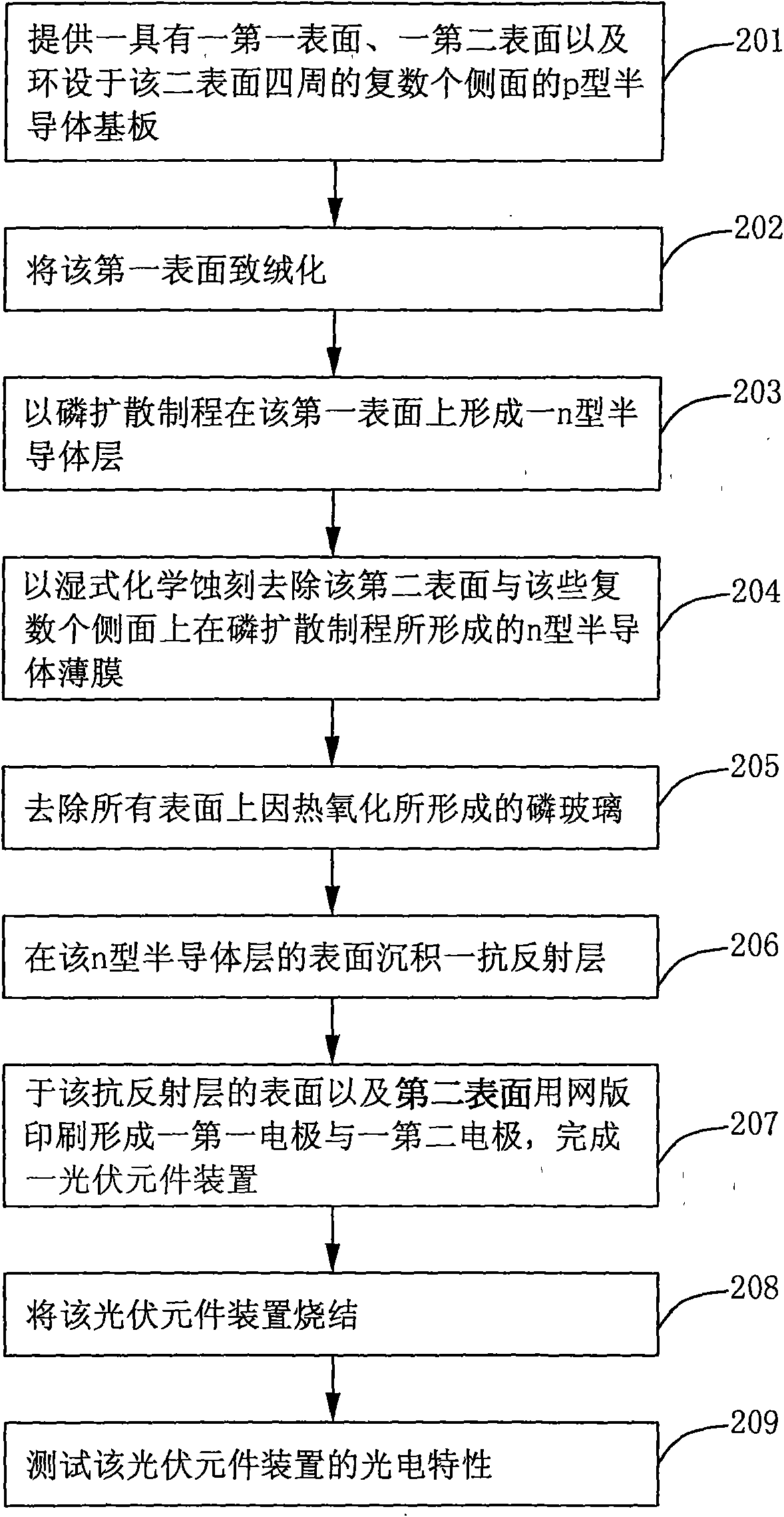

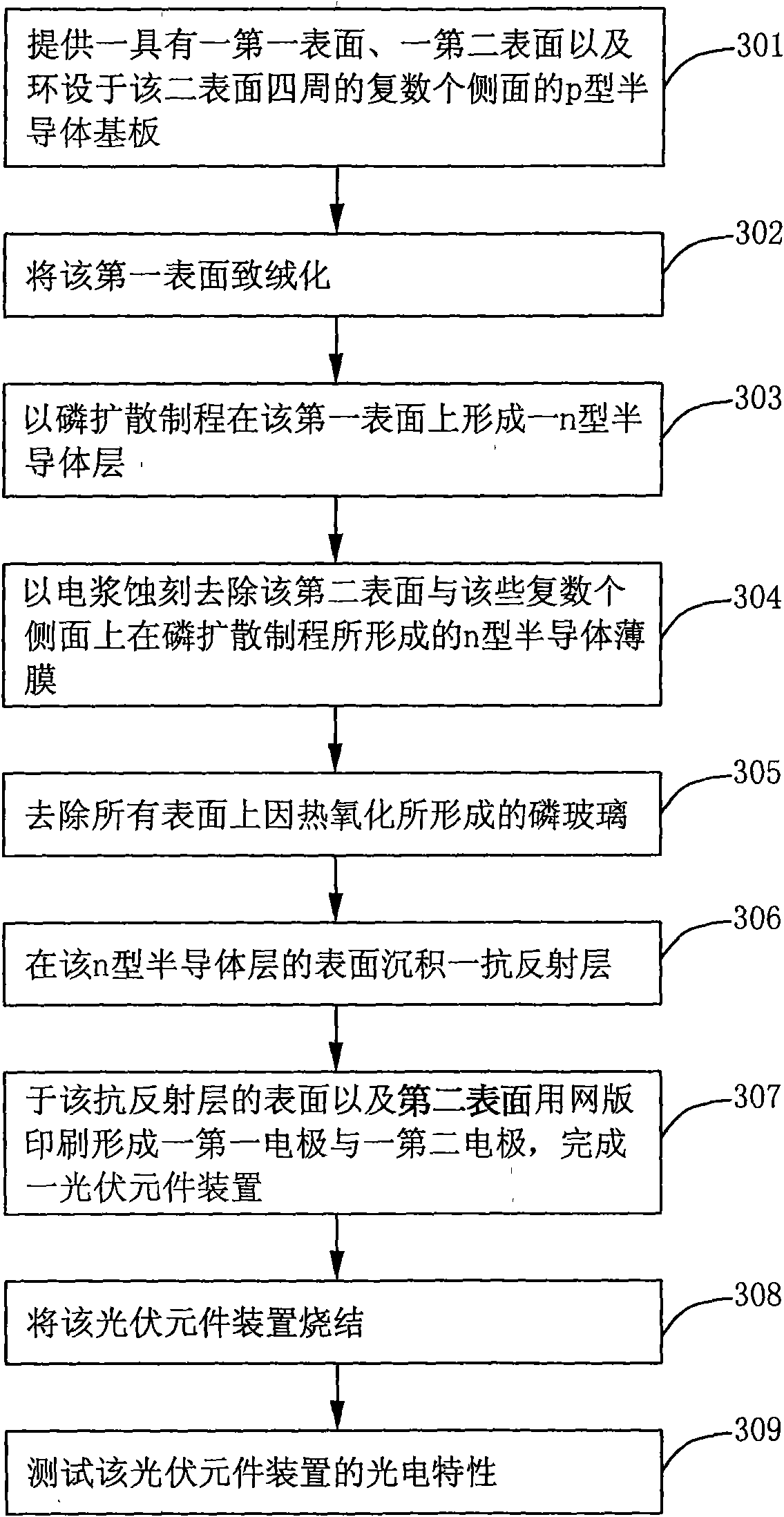

[0099] see Figure 4A As shown, the figure is a schematic diagram of the manufacturing process of the photovoltaic element device using the mask layer insulation method according to the first embodiment of the present invention. As shown in the figure, the manufacturing process of the photovoltaic element device in this embodiment includes the following steps:

[0100] Step 401: providing a first-type semiconductor substrate having a first surface, a second surface, and a plurality of side surfaces surrounding the two surfaces;

[0101] Step 402: Texturing the first surface;

[0102] Step 403: f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com