Voltage stabilization for grid-controlled x-ray tubes

一种X射线、控制电极的技术,应用在X射线设备、用于放射诊断的仪器、应用等方向,能够解决飞弧危险、危害、拍摄时间相互影响等问题,达到改善电压恒定、避免电压尖峰的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

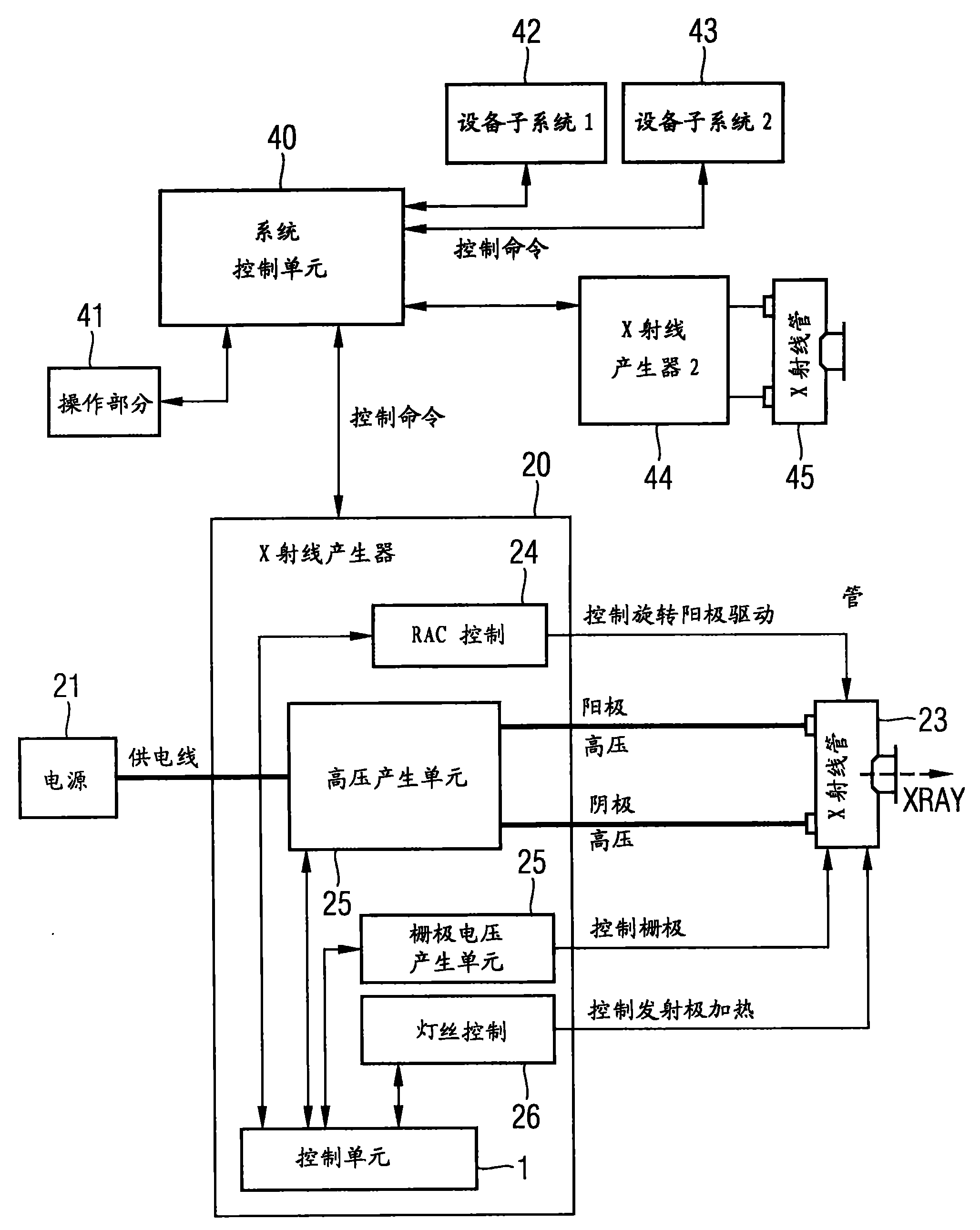

[0027] figure 1 A schematic diagram typical for current equipment is shown of the components of the X-ray tube. X-ray generator 20 includes control unit 1 and components: inverter / high voltage generator 22, anode drive 24 (RAC: Rotation Anode Control, rotating anode control), grid voltage generation unit 25 and for X-ray tube 23 Control unit 26 for cathode or emitter heating. Furthermore, a power supply 21 is also shown in the figure. By means of these elements, the required voltages (anode or cathode voltage and grid voltage) and other signals (control rotating anode drive, control emitter heating, . . . ) are provided for the X-ray tube 23 . X-rays XRAY are generated by means of an X-ray tube 23 . Furthermore, there is a central control unit 40 with an operating element 41 . The control of further devices 42 and 43 as well as of a second x-ray generator 44 , which drives a further x-ray tube 45 , is provided by means of the control unit 40 .

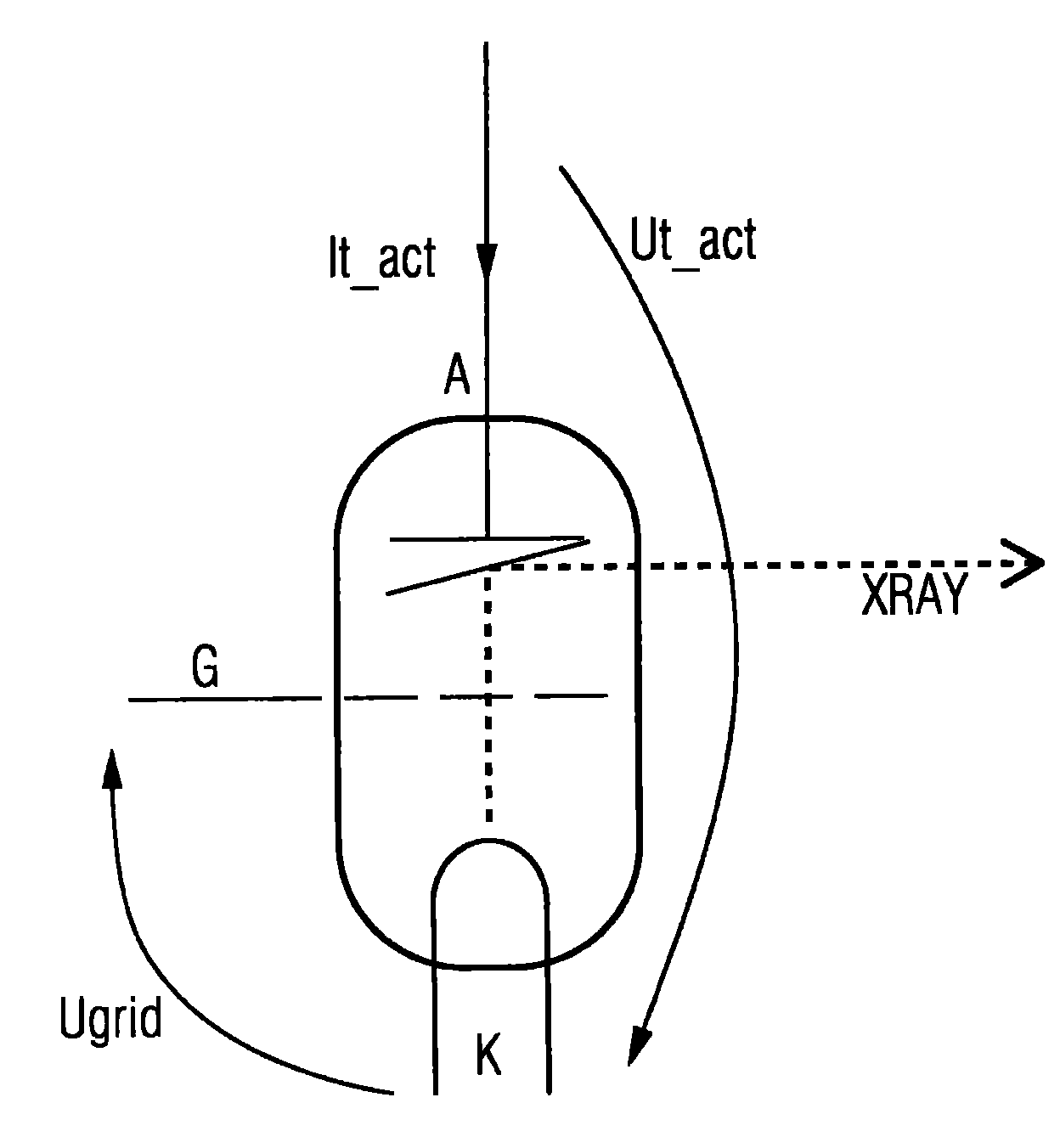

[0028] figure 2 An X-ray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com