Cosmetic bottle with corrosion preventing cap

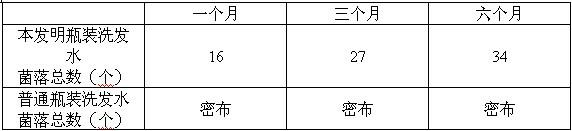

A technology of cosmetics and anti-corrosion caps, which is applied to packaging cosmetics, cosmetic powder containers, caps with auxiliary devices, etc., can solve hygiene problems, bacterial growth and other problems, and achieve the effect of simple structure, wide application, and avoiding bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

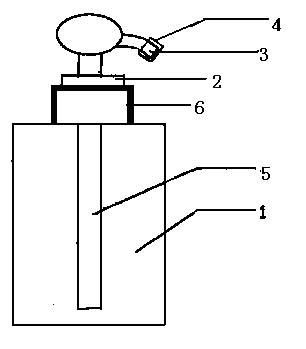

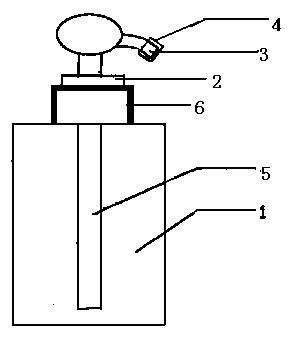

[0013] A cosmetic bottle with an anti-corrosion cap, comprising a bottle body (1), a liquid suction pump (2), a liquid outlet (3), an anti-corrosion cap (4), a straw (5), and a bottle mouth (6);

[0014] The liquid suction pump (2) is connected with the suction pipe (5), and then connected with the bottle mouth (6) on the bottle body (1) through a sealing rubber ring; the liquid outlet of the liquid suction pump (2) ( 3) Connect with the anti-corrosion cover (4).

[0015] The liquid outlet (3) is directly connected with the anticorrosion cover (4).

[0016] An antiseptic antibacterial agent zinc pyrithione is added to the anti-corrosion cover (4), and the added amount is 2% of the mass of the anti-corrosion cover.

Embodiment 2

[0018] A cosmetic bottle with an anti-corrosion cap, comprising a bottle body (1), a liquid suction pump (2), a liquid outlet (3), an anti-corrosion cap (4), a straw (5), and a bottle mouth (6);

[0019] The liquid suction pump (2) is connected with the suction pipe (5), and then connected with the bottle mouth (6) on the bottle body (1) through a sealing rubber ring; the liquid outlet of the liquid suction pump (2) ( 3) Connect with the anti-corrosion cover (4).

[0020] The liquid outlet (3) is connected with the anticorrosion cover (4) through threads.

[0021] The material of the anti-corrosion cover (4) is added with an anti-corrosion antibacterial agent, zinc oxide, in an amount of 3% of the mass of the anti-corrosion cover.

Embodiment 3

[0023] A cosmetic bottle with an anti-corrosion cap, comprising a bottle body (1), a liquid suction pump (2), a liquid outlet (3), an anti-corrosion cap (4), a straw (5), and a bottle mouth (6);

[0024] The liquid suction pump (2) is connected with the suction pipe (5), and then connected with the bottle mouth (6) on the bottle body (1) through a sealing rubber ring; the liquid outlet of the liquid suction pump (2) ( 3) Connect with the anti-corrosion cover (4).

[0025] The liquid outlet (3) is connected with the anticorrosion cover (4) through threads.

[0026] The anti-corrosion cover (4) and the liquid outlet (3) are added with an antiseptic antibacterial agent ammonium dihydrogen phosphate, and the added amount is 5% of the mass of the materials of the anti-corrosion cover and the liquid outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com