Automatic cleaning device for viscosity meter

An automatic cleaning and viscometer technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high pollution, impossibility, and high noise, and achieve strong scalability, simple control, and cleaning high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] based on the following Figure 1 ~ Figure 3 , specify the preferred embodiment of the present invention:

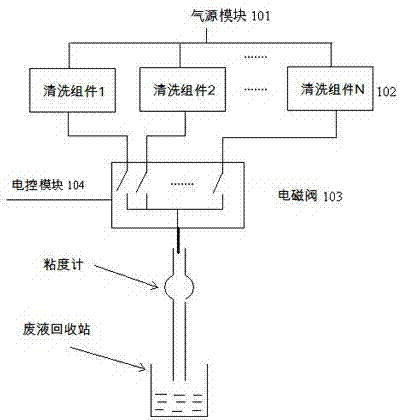

[0021] Such as figure 1 As shown, it is a structural schematic diagram of an automatic cleaning device for viscometer provided by the present invention. The automatic cleaning device includes an air source module 101 connected in sequence, several cleaning components 102, a solenoid valve 103, and also includes the circuit connection described The electric control module 104 of the solenoid valve 103.

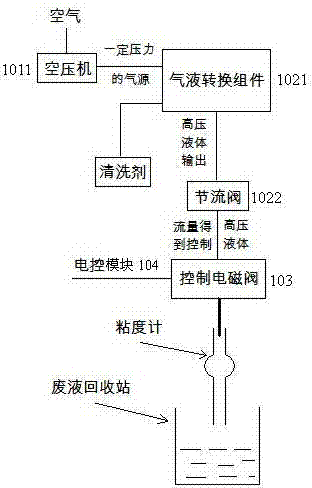

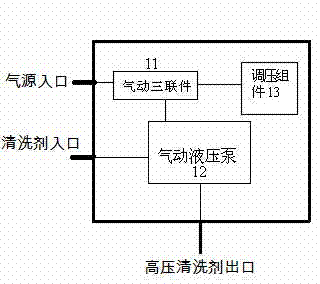

[0022] Such as figure 2 As shown, the air source module 101 is the original power of the entire automatic cleaning device, generally 3-10 kg of air or nitrogen. If the atmosphere is directly used as the power, an air compressor 1011 needs to be set in the air source module 101 to Gas with a certain pressure is provided to the cleaning device 102. The automatic cleaning device does not have too high requirements on the purity of the gas source and the stability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com