Protection device for gas-protective welding

A protective device and gas shielding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high cost, large gas consumption, difficult to effectively control, etc., and achieve welding quality improvement, cost reduction, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

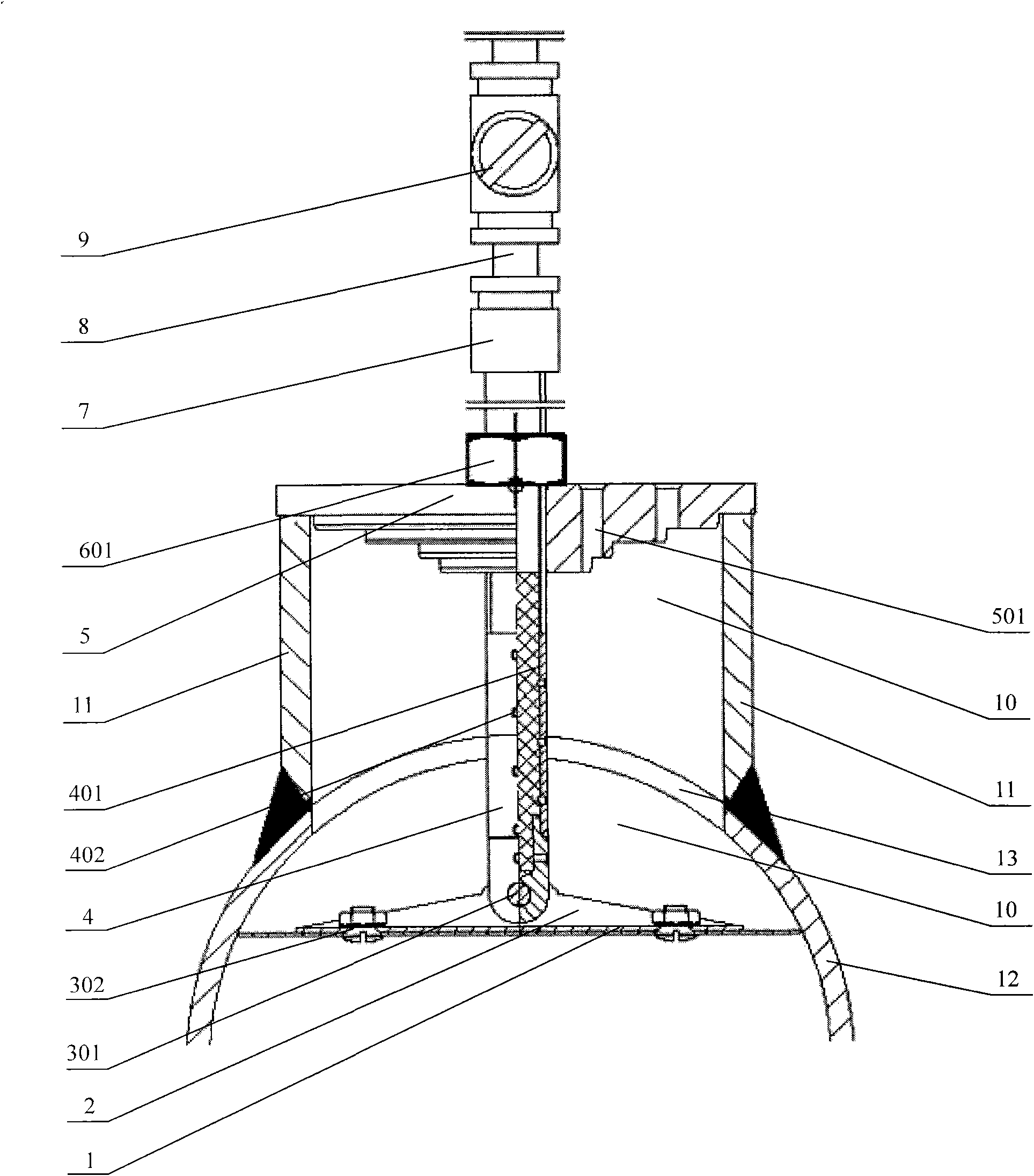

[0042] Such as figure 1 As shown, the protection device of the present invention for gas shielded welding of three-way pipe intersecting line welding includes a gas control valve 9, a gas pipe 8, a conversion joint 7, a centering cover plate 5, a gas guide rod 4, and a supporting rib 2. , Sealing cover 1.

[0043] The shielding gas flows in through the air pipe 8. A gas control valve 9 is provided at the entrance of the air pipe 8 to control the flow and flow rate of the shielding gas. The two ends of the adapter 7 are threaded pairs to connect the air pipe 8 with the connecting rod 4; The air guide rod 4 has an external thread structure and is fixed to the centering cover plate 5 by a nut 601.

[0044] The connecting air rod 4 is a hollow structure, and the evenly distributed air outlet 402 is provided on the wall of the connecting air rod 4 to fill the protective gas in the connecting air rod 4 into the gas protection cavity 10; the connecting air rod 4 has a built-in wire The n...

Embodiment 2

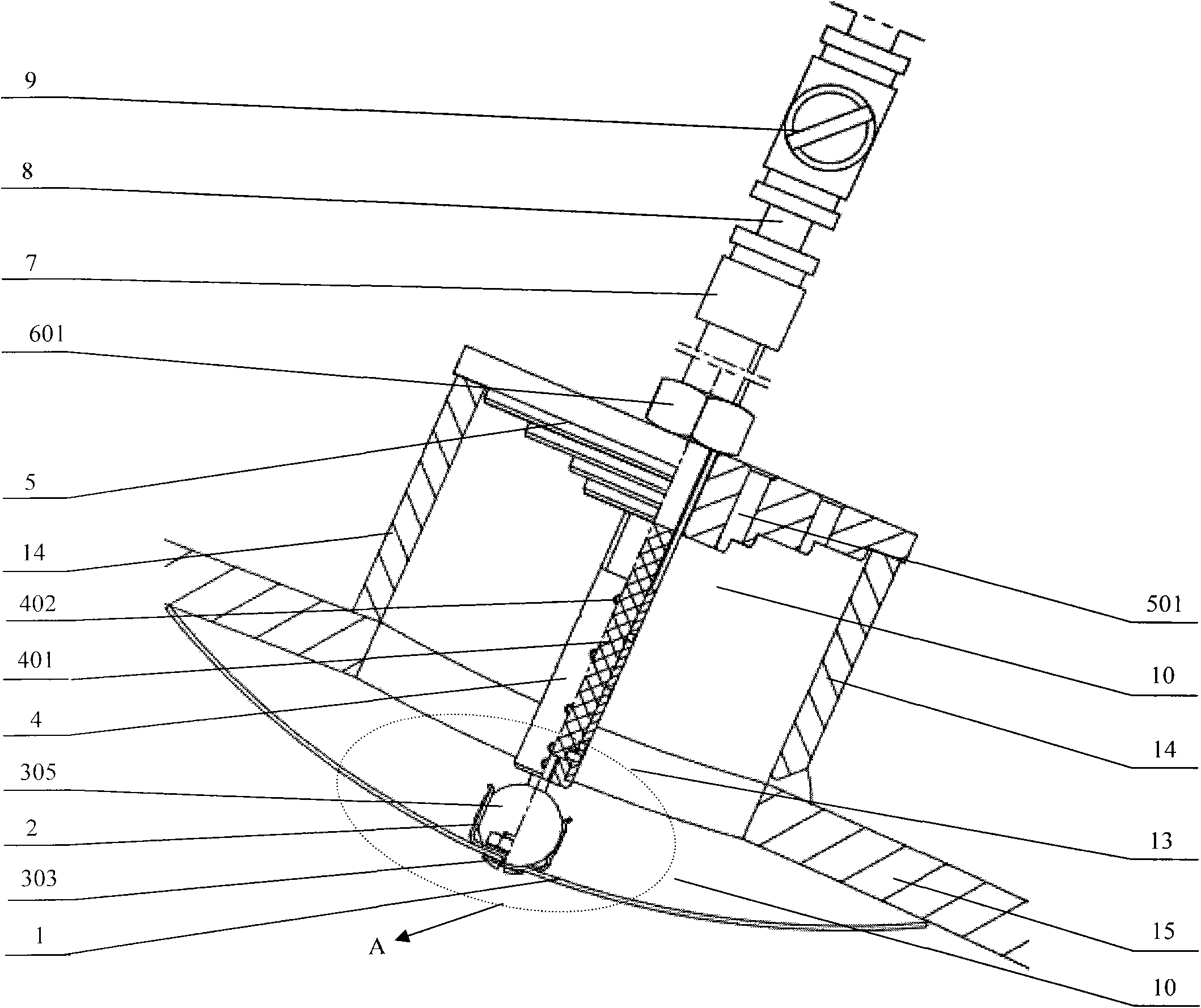

[0048] Such as figure 2 As shown, the protection device of the present invention for the gas shielded welding of the welding seam of the intersecting line of two rotating curved surfaces of the elliptical head includes a gas control valve 9, a gas pipe 8, a conversion joint 7, a centering cover plate 5, and a gas guide rod 4, Support rib 2, seal cover 1.

[0049] The shielding gas flows in through the air pipe 8. A gas control valve 9 is provided at the entrance of the air pipe 8 to control the flow and flow rate of the shielding gas. The two ends of the adapter 7 are threaded pairs to connect the air pipe 8 with the connecting rod 4; The air guide rod 4 has an external thread structure and is fixed to the centering cover plate 5 by a nut 601.

[0050] The connecting air rod 4 is a hollow structure, and the evenly distributed air outlet 402 is provided on the tube wall of the connecting air rod 4 to fill the protective gas in the connecting air rod 4 into the gas protection cavity...

Embodiment 3

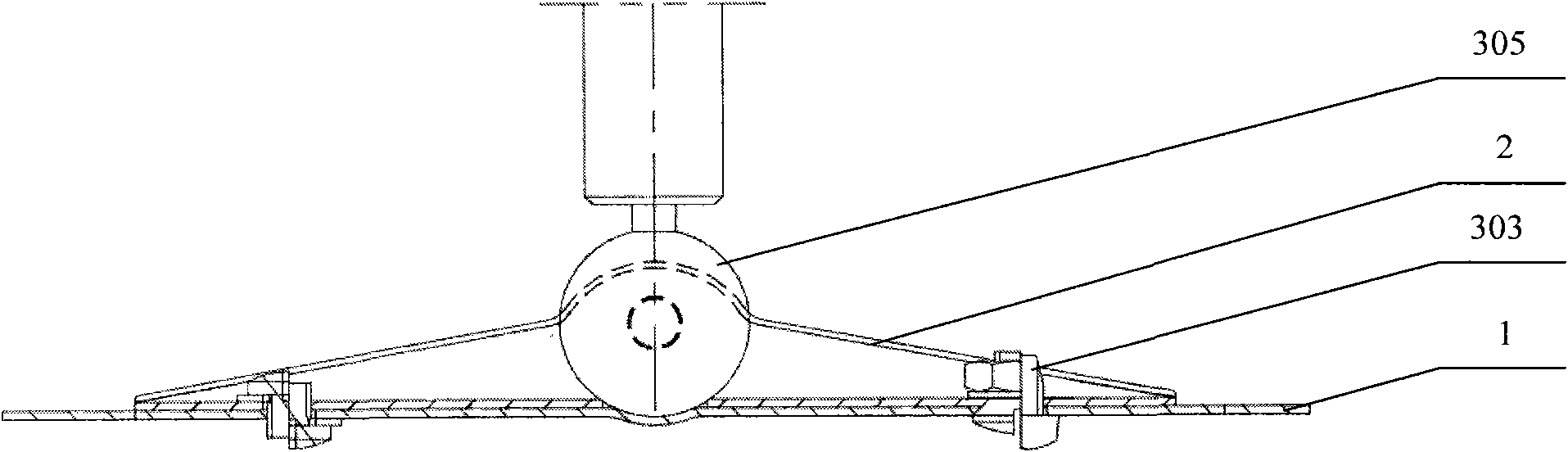

[0055] Such as Figure 4 As shown, the protection device of the present invention for the gas shielded welding of the intersecting line of two rotating curved surfaces of an elliptical head includes a gas control valve 9, a gas pipe 8, a conversion joint 7, a centering cover plate 5, and a gas guide rod 4. Support rib 2, seal cover 1.

[0056] The shielding gas flows in through the trachea 8. A gas control valve 9 is provided at the entrance of the trachea 8 to control the flow and velocity of the shielding gas. The two ends of the adapter 7 are threaded pairs to connect the trachea 8 and the connecting rod 4; The air guide rod 4 and the centering cover plate 5 are firmly connected by an eccentric sleeve 602.

[0057] The connecting air rod 4 is a hollow structure, and the evenly distributed air outlet 402 is provided on the wall of the connecting air rod 4 to fill the protective gas in the connecting air rod 4 into the gas protection cavity 10; the connecting air rod 4 has a built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com