Device and method for controlling three degree of freedom hybrid drive flexible cable parallel robot

A hybrid drive and control device technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of insufficient motion flexibility, stability and accuracy of hybrid-driven flexible-cable parallel robots, and achieve perfect motion flexibility. , Good versatility, real-time adjustment of outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

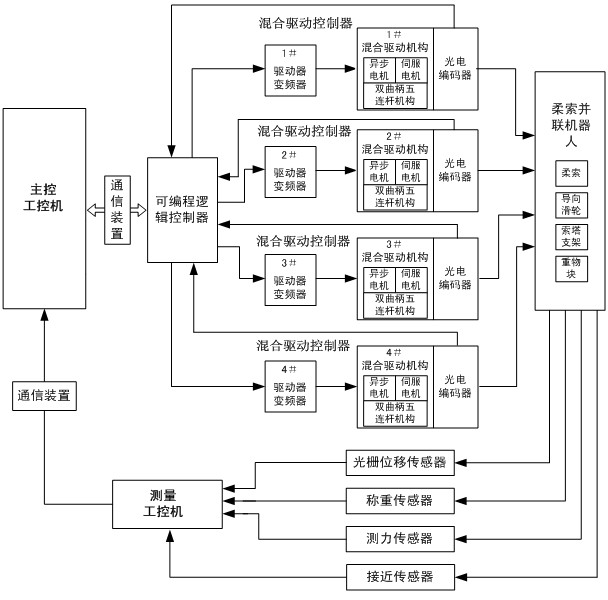

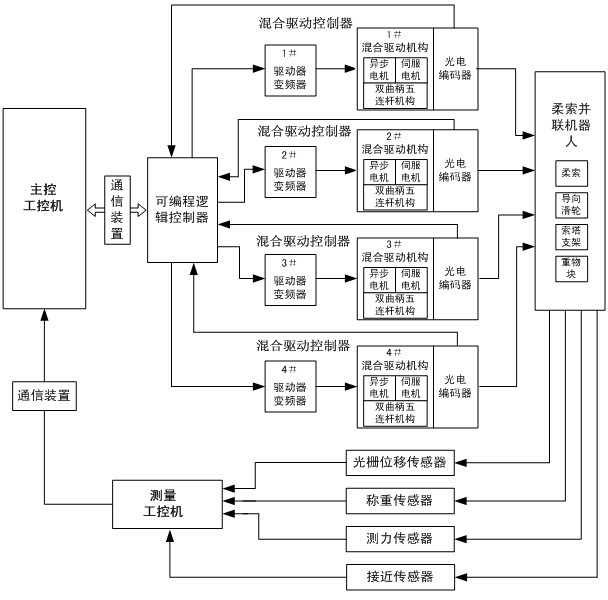

[0020] Example 1: figure 1 Among them, the robot control device includes a flexible cable parallel robot, a hybrid drive controller, a sensor, a main control industrial computer, a measurement industrial computer, a communication device and a programmable logic controller, and the main control industrial computer is connected to the programmable logic controller through the communication device , the output end of the hybrid drive controller is connected with the flexible cable parallel robot, the flexible cable parallel robot is connected with the measuring industrial computer through the sensor, and the measuring industrial computer is connected with the main control industrial computer through the communication device.

[0021] The hybrid driving mechanism includes an AC three-phase asynchronous motor, an AC servo motor and a double-crank five-bar linkage, the AC three-phase asynchronous motor and the AC servo motor are respectively connected to the two cranks of the double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com