Method for extracting chilli oil resin from chilli

A technology of capsicum oleoresin and capsicum, applied in natural resin technology, chemical instruments and methods, bulk chemical production, etc., can solve problems such as poor safety, achieve stable product performance, and improve the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

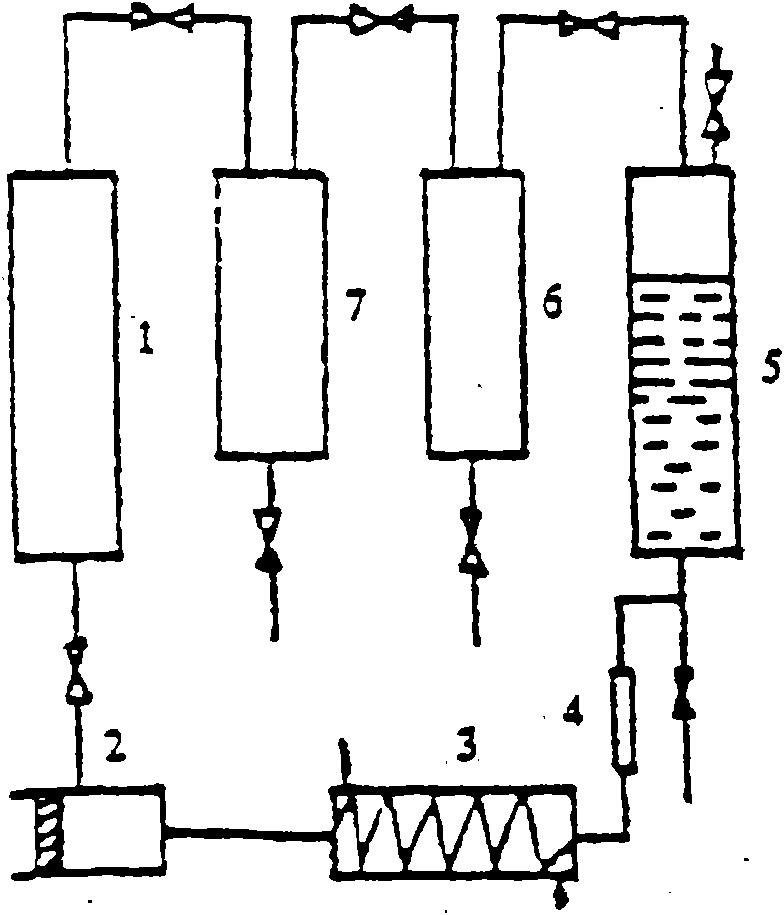

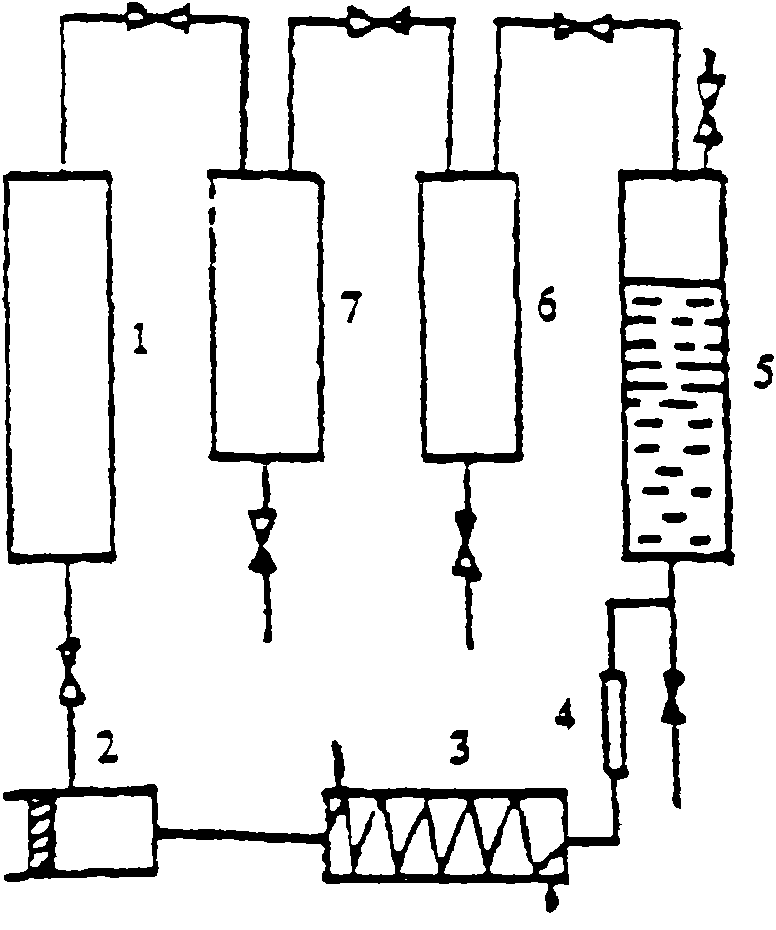

[0021] 1. Using supercritical CO 2 Extraction and separation of capsicum oleoresin:

[0022] (1) Pulverize and dry the chili powder into chili powder; (2) put the chili powder into supercritical CO 2 In the extraction kettle 5, heat the preheater 3 with circulating hot water, and adjust the temperature of the extraction kettle and the separators 6 and 7 connected thereto to 40-60°C; (3) the CO 2 CO in tank 1 2 The supercritical gas is generated after being injected into the preheater by the metering pump 2, and then enters the CO after being metered by the meter 4. 2 Extraction kettle 5; (4) when CO 2 When passing through the material layer, the capsicum oleoresin contained in the paprika is dissolved in supercritical CO 2 In the gas, when the extraction pressure is reached, slowly open the outlet valve of the extractor to keep the extraction pressure stable at 26-28Mpa; (5) supercritical CO 2 Together with its dissolved substances, it is separated by separators 6 and 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com