Adjustable laser coaxial powder-feeding nozzle

A coaxial powder feeding and adjustable technology, which is applied in the direction of spraying devices and liquid spraying devices, can solve the problems of powder accumulation inside the nozzle, poor powder ejection at the outlet, blockage of the nozzle, and powder deposition, etc., to improve the universality of the equipment High performance, large adjustment range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

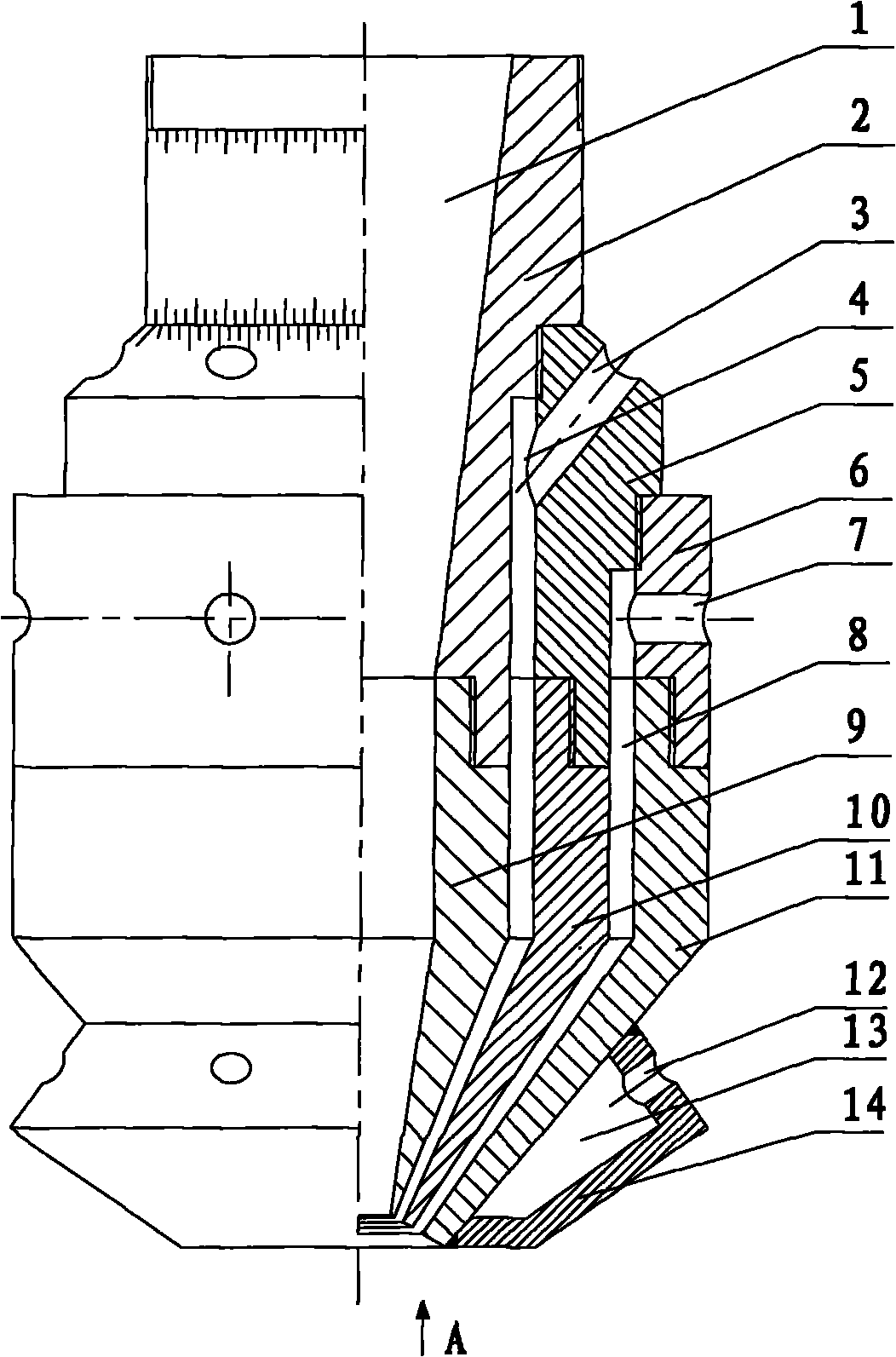

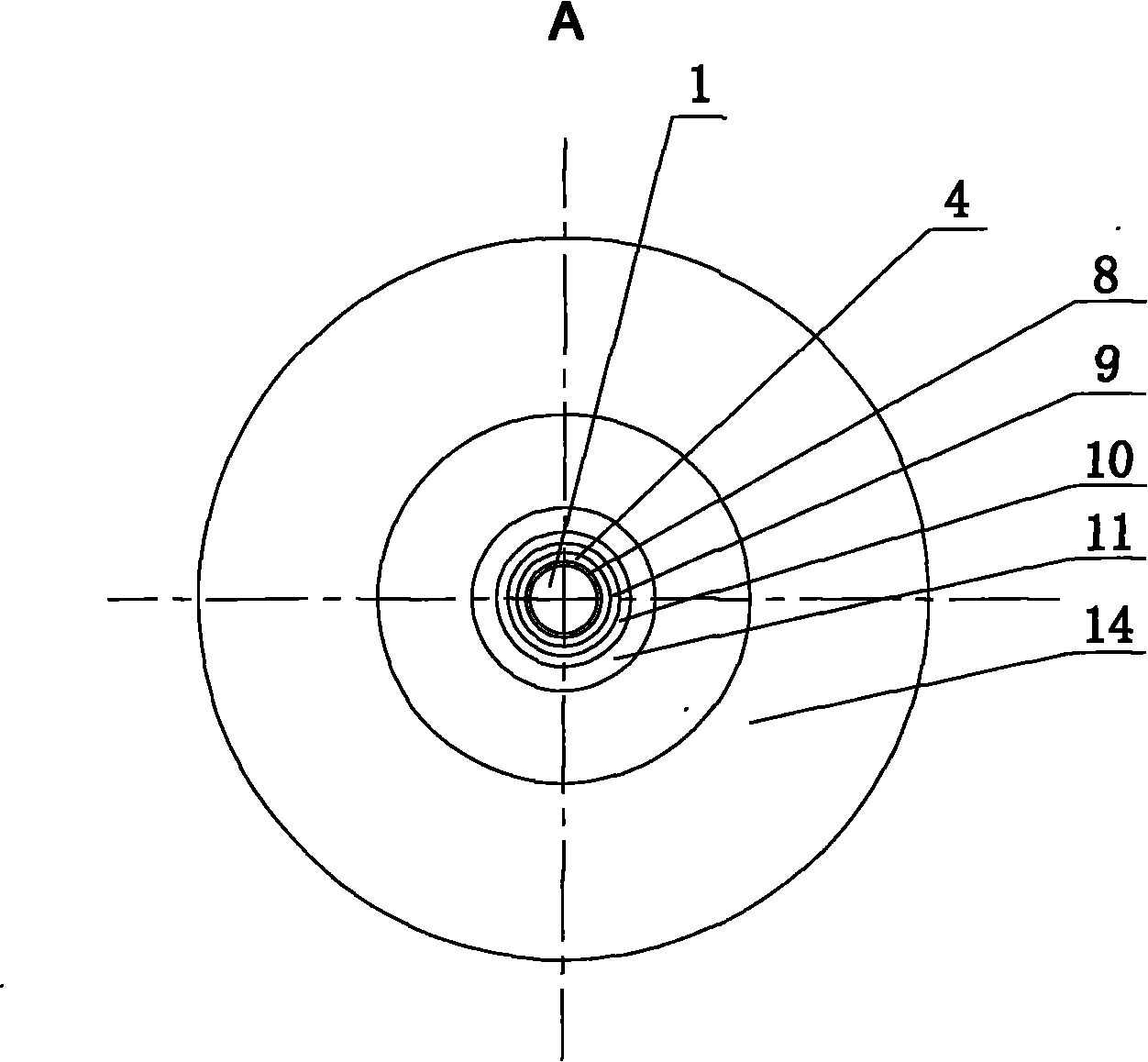

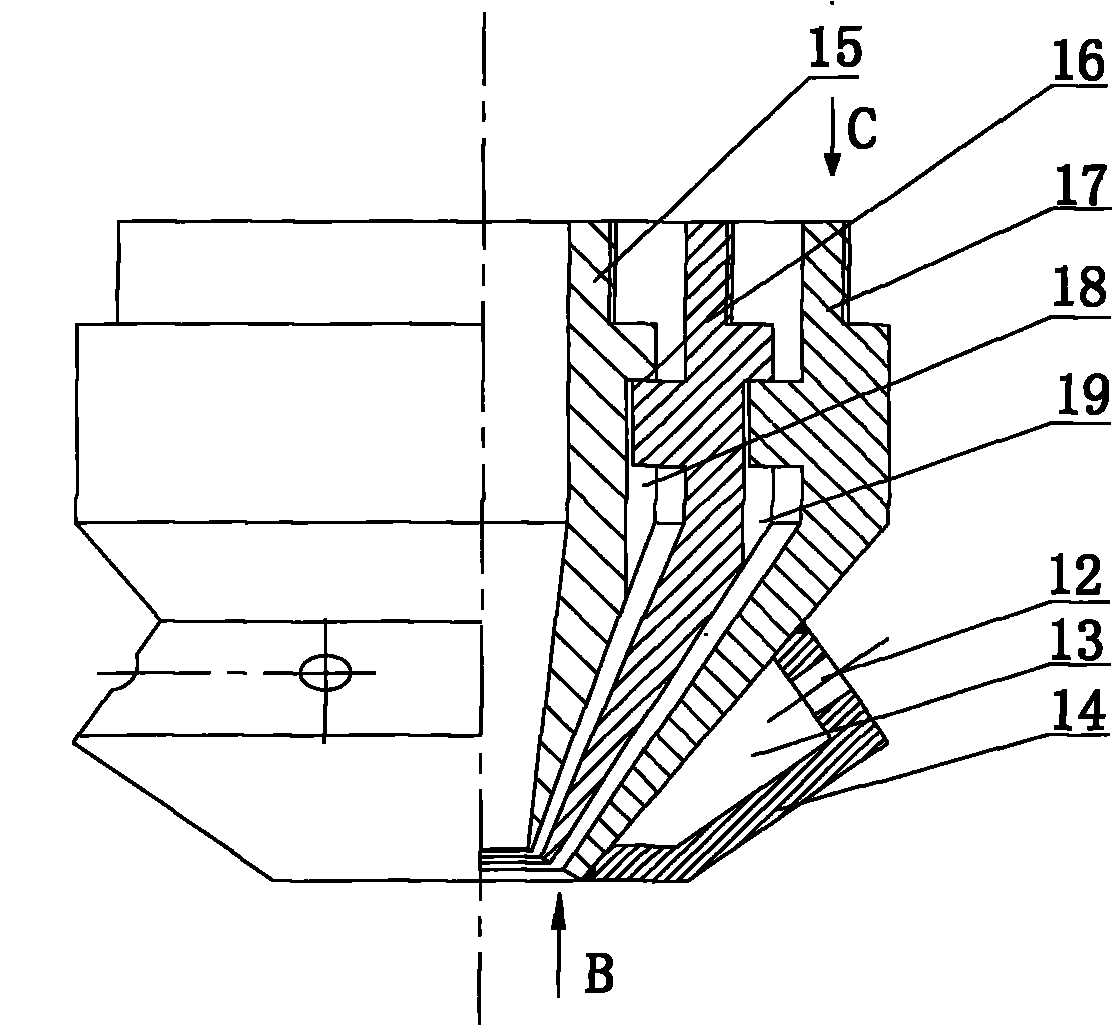

[0017] The present invention connects the laser device and the powder cylinder 5 respectively by the connecting cylinder 2 marked with the scale, and utilizes the screw thread to form a mechanism that can be adjusted vertically up and down. The cone 10 and the outer cone 11 of the circular outlet are respectively connected to the upper body by threads. One group is composed of the inner cone 15 of the square outlet coaxially distributed, the middle cone 16 of the square outlet, and the outer cone 17 of the square outlet. According to different laser spot types, the lower body of the corresponding outlet is installed to realize the adjustment of the belt-shaped or circular powder fusion coating.

[0018] The lower body is composed of three coaxially distributed cones with rectangular outlets. Three bosses are evenly distributed on the inner walls of the middle cone 16 of the square outlet and the outer cone 17 of the square outlet. The inner cone 15 of the square outlet and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com