Light-material hollow floor system internal mould

A technology of lightweight materials and internal molds, applied in floors, building components, buildings, etc., can solve the problems of affecting the quality of concrete pouring, debris polluting the construction environment, and high production costs, achieving good economy, applicability, and smooth surface Easy, material-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The patent of the present invention is realized in the following manner:

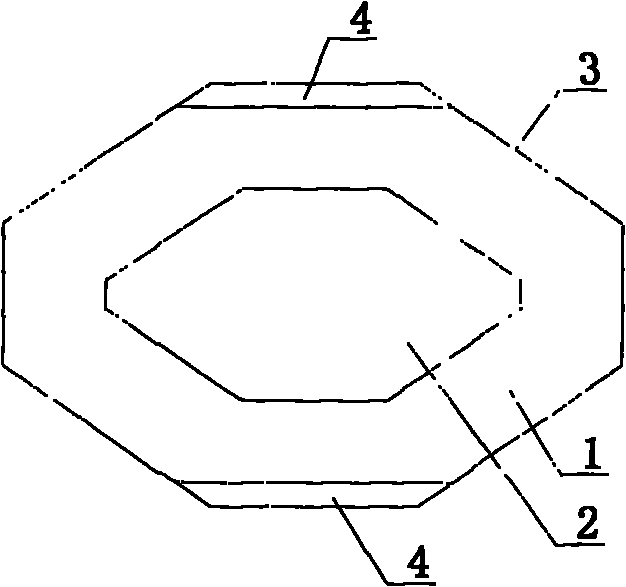

[0012] 1. The patent of the present invention includes a body (1), which is hollow (2), surrounded by a wrapping layer (3), and a reinforcing layer (4) between the wrapping layer and the body. Hollow (2) also can cancel.

[0013] 2. First, use light materials (such as polystyrene foam, polyvinyl chloride foam, polyurethane foam, expanded perlite, foamed concrete, foamed concrete and other low-density materials) as the base material to produce filler parts. ontology.

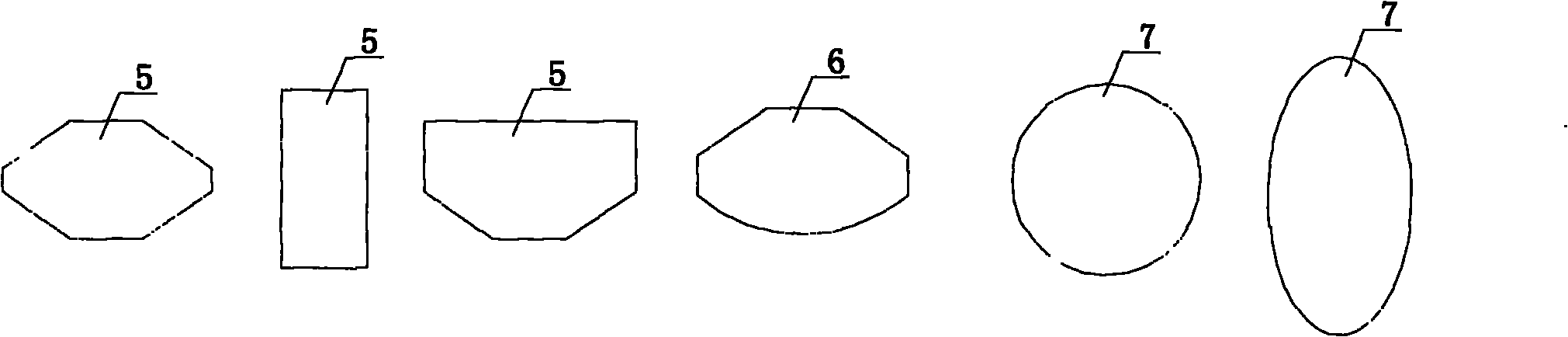

[0014] 3. The cross-section and longitudinal dimensions of the body are in accordance with the design requirements. The cross-sectional shape can be polygonal (5), or a combination of straight lines and arcs (6), circular or elliptical (7); the body can also be made into box.

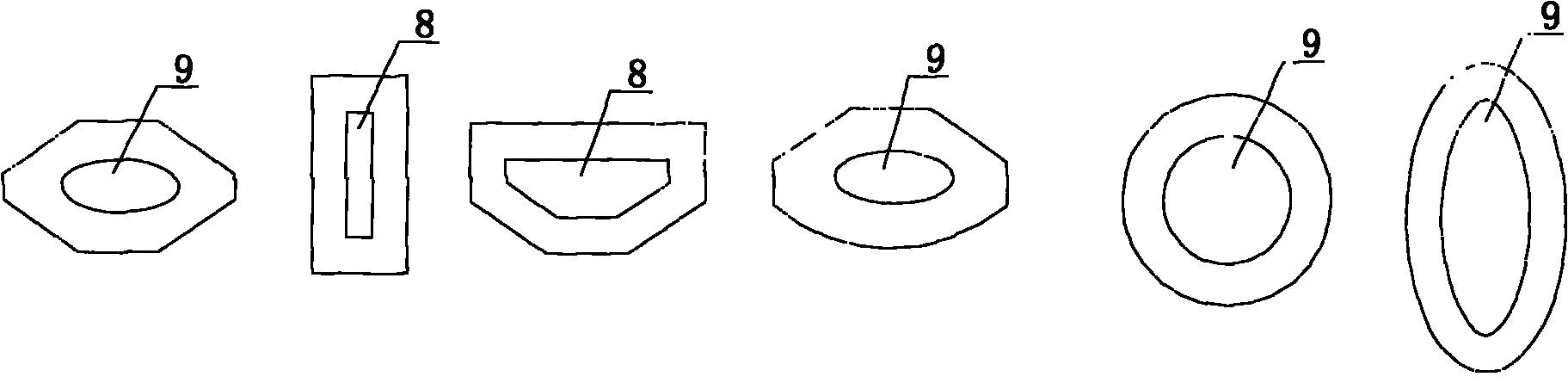

[0015] 4. Dig out a polygonal hole (8) or a circular (elliptical) hole (9) in the middle of the body.

[0016] 5. Apply or paste a hard reinforcement lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com