Method of detecting filling of hydraulic clutch

A hydraulic clutch, friction clutch technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as uneven shift transmission lockup, engine knocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following description is merely exemplary in nature and does not limit the disclosure, application or uses thereof.

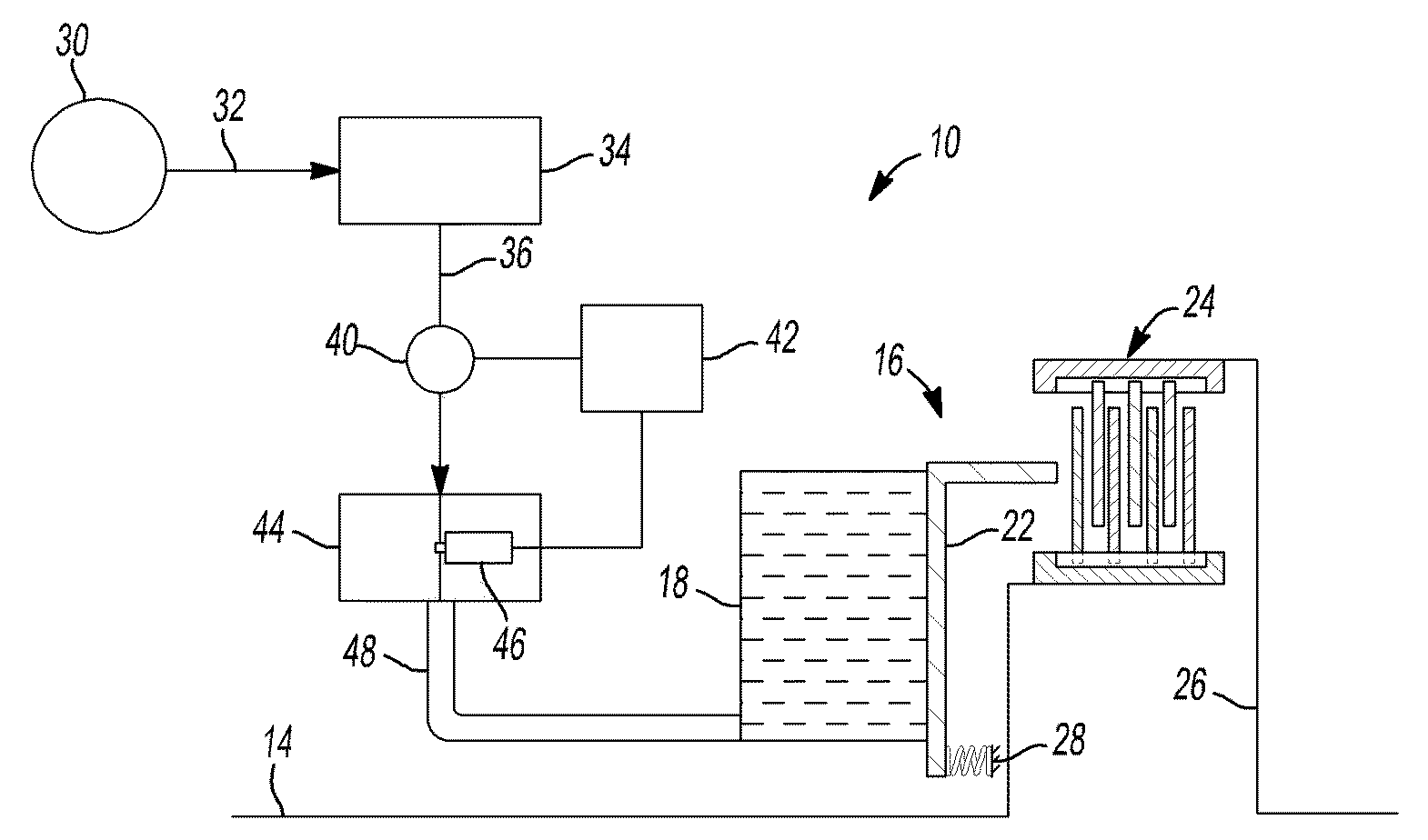

[0059] Reference attached figure 1 , shows a portion of an automatic transmission incorporating the present invention, which is generally indicated by reference numeral 10 . Automatic transmission 10 includes a rotatable input shaft 14 that provides drive torque from a prime mover (not shown), such as a gasoline engine, diesel engine, flex fuel engine, hybrid or electric machine, to a clutch pack 16 . It should be understood that the clutch pack 16 is representative only, that multiple clutches are typically used in a transmission, and that clutch locations may be at the input of the transmission, within the transmission, or both. The clutch assembly 16 includes a hydraulic cylinder 18 that houses a hydraulic apply piston 22 that is slidable in both directions. The hydraulic apply piston 22 acts on and compresses or releases an associated friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com