Detection method of soluble heavy metals contained in dye

A detection method and soluble technology, applied in the direction of color/spectral characteristic measurement, test sample preparation, etc., can solve the problems of no drying time, difficult operation, no specified temperature value, etc., and achieve simple and easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

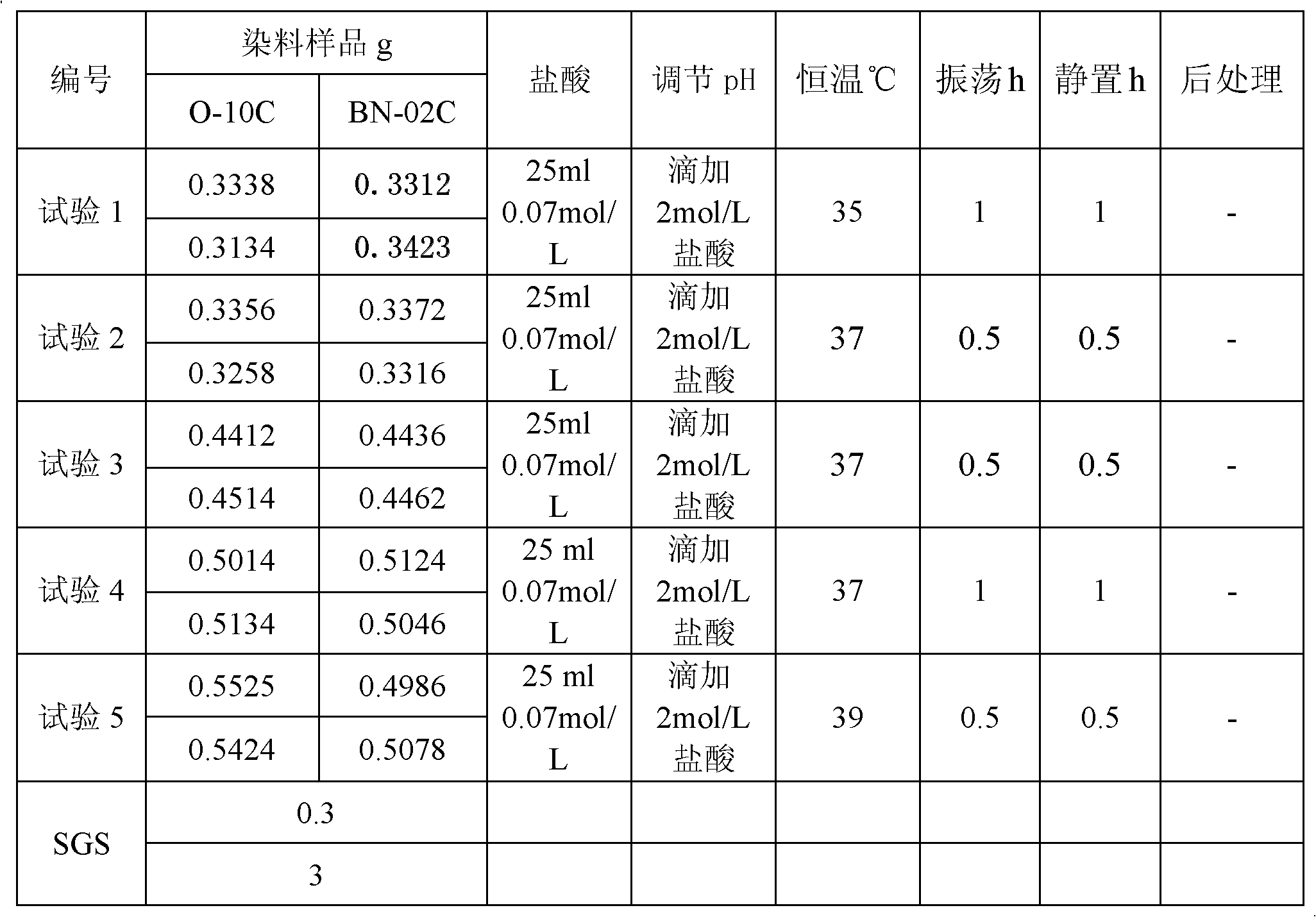

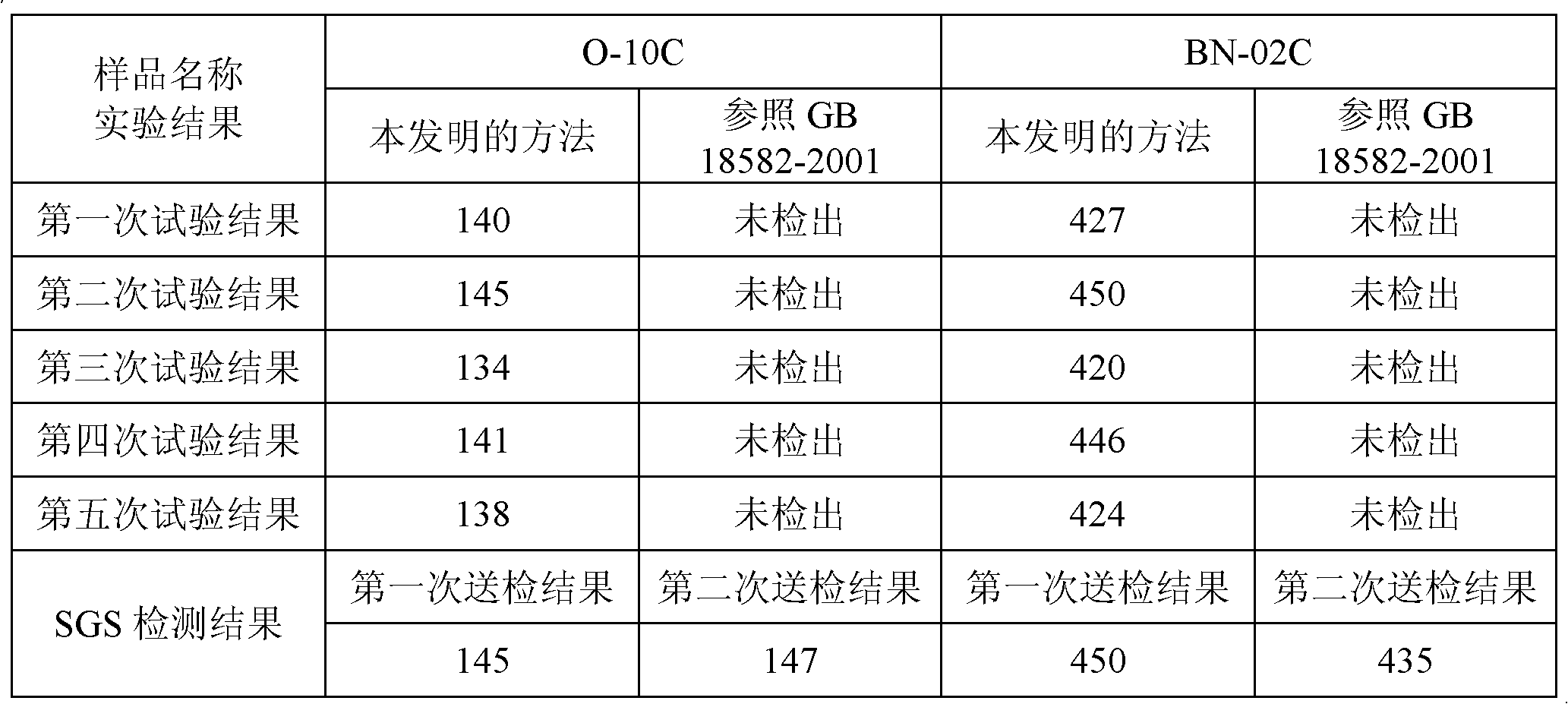

[0021] A detection method for soluble heavy metals contained in a dye, characterized in that it comprises the following steps:

[0022] (1) Weigh about 0.3-0.5g of dye sample (accurate to 1mg), and put it into a 150-200ml beaker;

[0023] (2) Add 25ml of 0.07mol / L hydrochloric acid and mix to measure the acid value. If the pH>1.5, gradually add 2mol / L hydrochloric acid solution dropwise and shake well to make the pH between 1.0-1.5;

[0024] (3) Then wrap a protective film on the mouth of the beaker and put it in a constant temperature oscillating water tank, continuously oscillate the mixed solution at a temperature of 37±2°C for 0.5 to 1 hour, and then let it stand for 0.5 to 1 hour;

[0025] (4) Immediately filter with qualitative filter paper and store away from light. The test should be completed within 4 hours; if the test cannot be completed within 4 hours, 25ml of 1mol / L hydrochloric acid solution should be added to process the sample.

[0026] Remark:

[0027] (1) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com