Enamelled wire quality on-line monitoring system

A monitoring system, enameled wire technology, applied in measurement devices, comprehensive factory control, instruments, etc., can solve the problems of unsuitable enameled wire online detection, limited detection capability, toxic mercury, etc., to save raw materials, reduce waste and defective products, and have complete functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

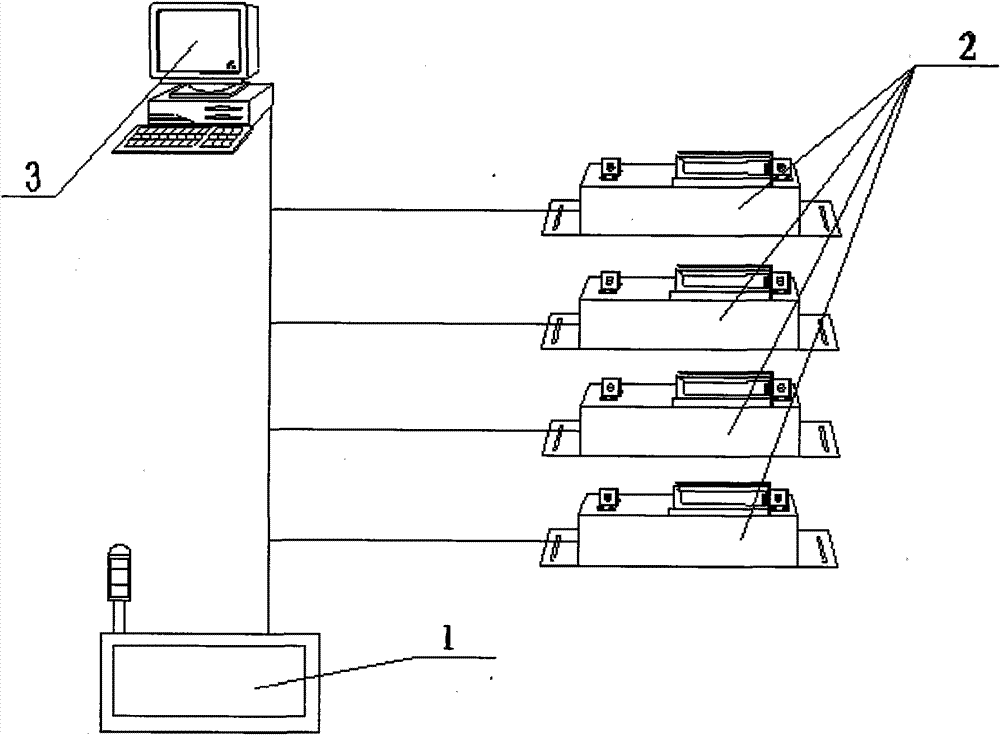

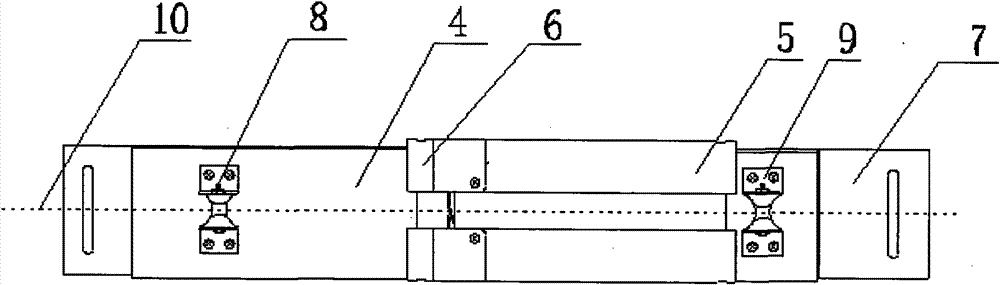

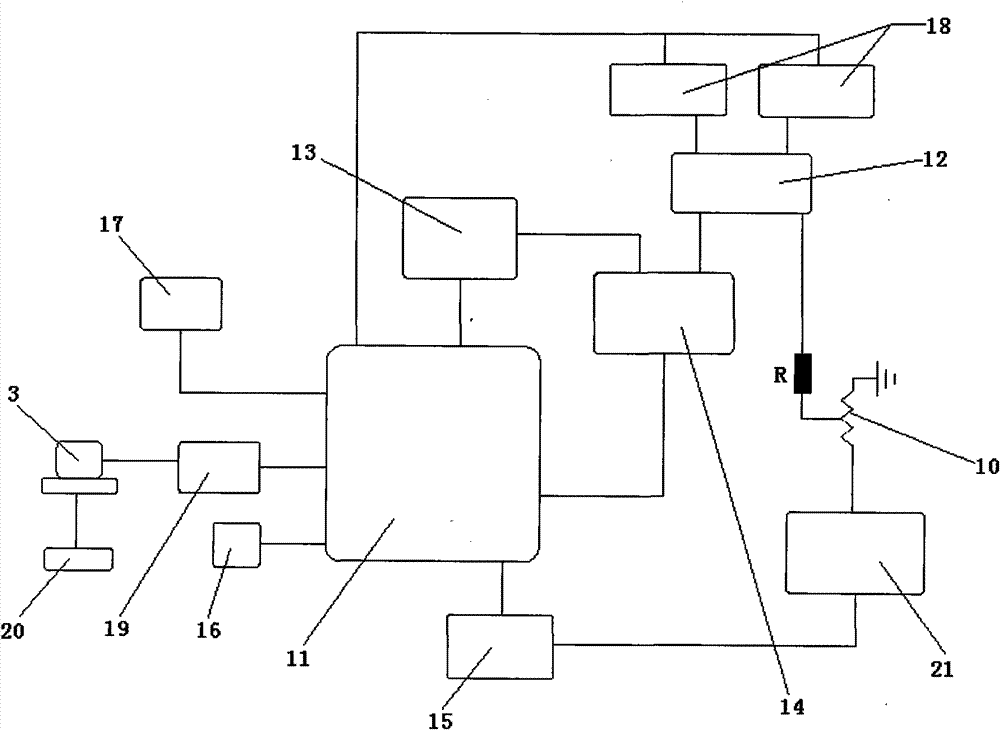

[0014] Such as Figure 1-3 As shown, an enameled wire quality online monitoring system according to an embodiment of the present invention includes a detector control box 1, a line detector 2, and a computer 3, and the detector control box 1 is connected to the computer 3 and several line detectors through lines respectively. 2, the line detector 2 includes a housing 4, a surface defect detection sensor 5 and a centering guide wheel 6, a detector control system is provided inside the housing, and the detector control system includes a logic controller 11, a signal amplifier 12 and Analog-to-digital converter 13, the logic controller 11 is respectively connected to the analog-to-digital converter 13, the multiplexer 14, the digital-to-analog converter 15, the crystal oscillator 16, the configuration device 17 and two acceleration sensors 18, and the logic controller 11 passes through The communication device 19 is connected to the computer 3, and the computer 3 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com