Automatic water mixing control system for sintering production

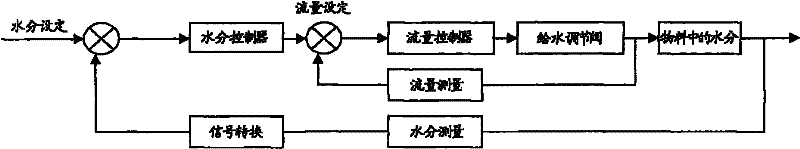

A control system and automatic water mixing technology, applied in the direction of various fluid ratio control, etc., can solve the problem that manual operation cannot obtain stable control quality, etc., and achieve the effect of reducing water fluctuation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

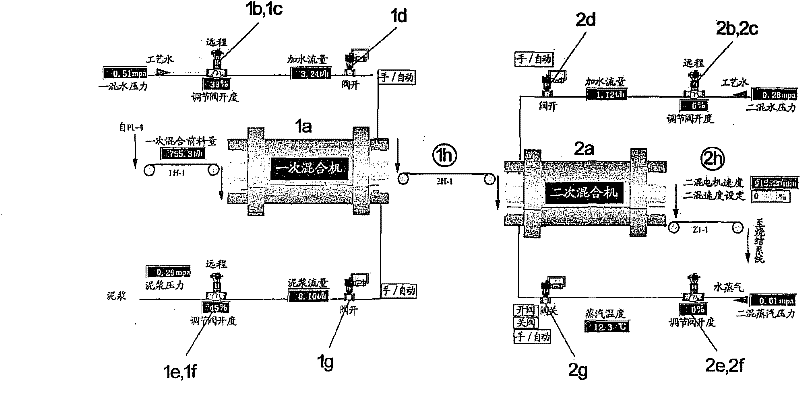

[0024] Preferred embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art will understand the features and advantages of the present invention from the accompanying drawings and corresponding descriptions.

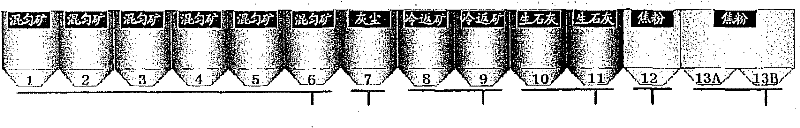

[0025] In the present invention, the sintered raw materials after batching are mixed twice and a certain amount of water is added each time they are mixed. Among them, adding water for the first time makes the water content of the mixture reach the target value set by the first time mixing and adding water. The amount of water reaches the target value set for the second mixing and adding water, which is beneficial to the pelletizing of the mixture, ensures good air permeability during sintering, and improves the output and quality of sintering ore.

[0026] In the present invention figure 1 A schematic diagram of the mixing and adding water system is shown in , which includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com