Device for producing electrical energy from exhaust gas heat

A technology of equipment and electric energy, applied in the field of equipment for generating electric energy from exhaust heat, can solve the problems of expensive, inefficient, and unsuitable for mass production of thermoelectric generators, and achieve a stable and strong cooling structure or heat exchange components , Improving the effect of turbulent flow and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

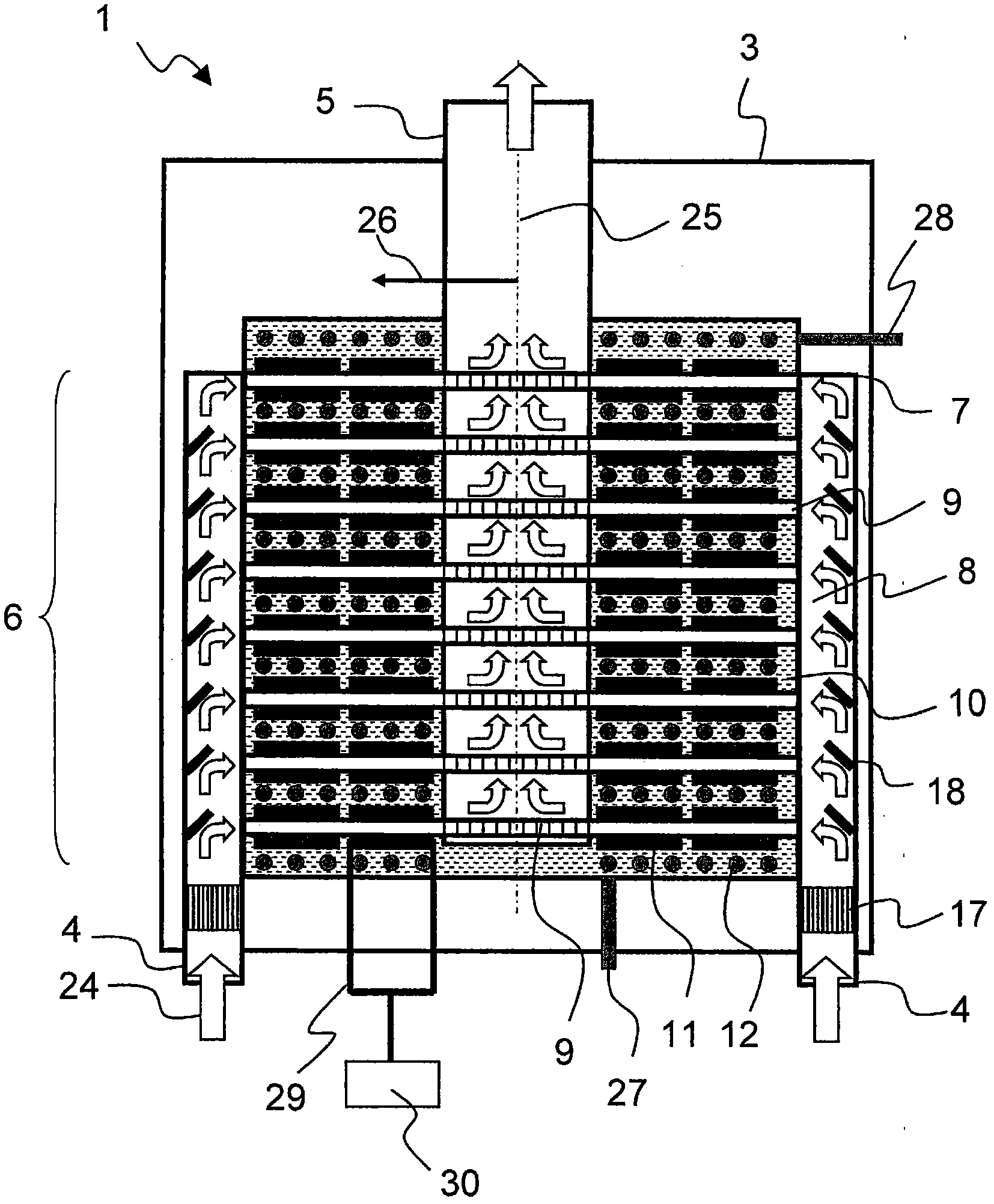

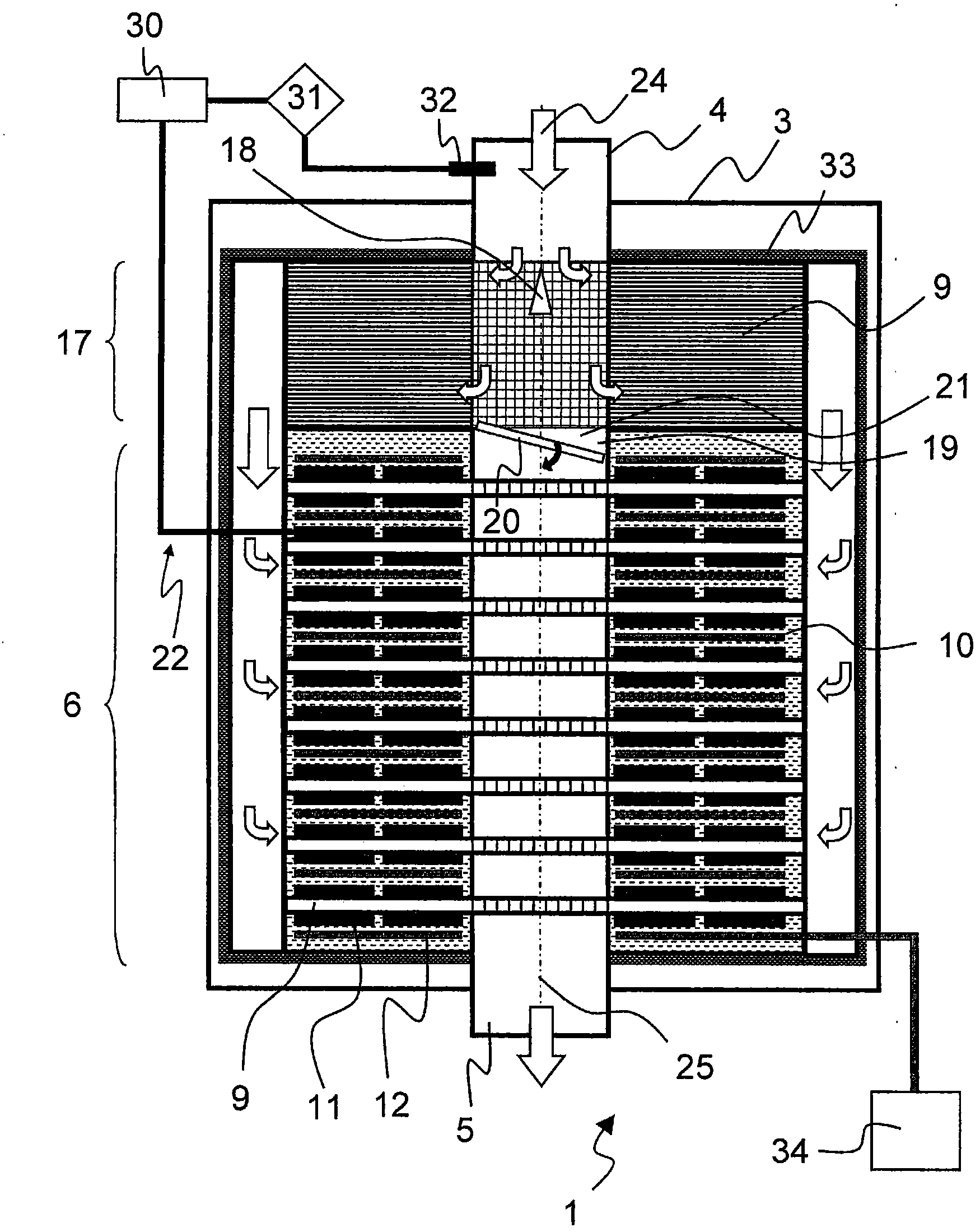

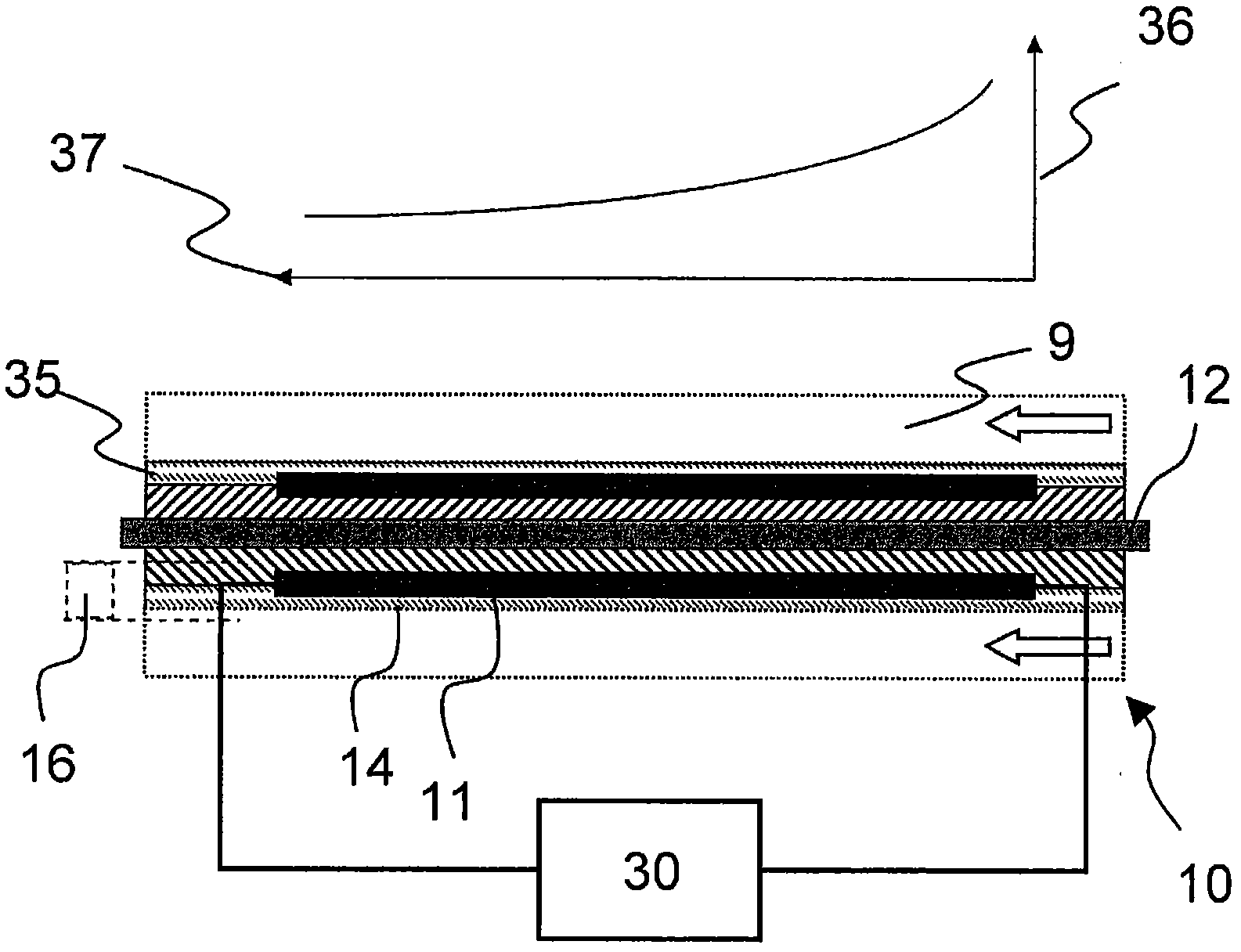

[0040] figure 1 A first embodiment of a device 1 according to the invention is shown for generating electrical energy from the exhaust gas of an engine 2 , not shown here. In the lower region, the device 1 has an annular channel which forms an exhaust gas inlet connection 4 . As indicated by the arrows, the entire exhaust gas flows into the generator 3 in a corresponding flow direction 24 . Initially the exhaust gas encounters a catalytic segment 17 , which is realized, for example, with a so-called honeycomb body in which a catalytically active coating is arranged. After passing through the catalytic section 17, the exhaust gas enters the heat exchange section 6, in which the exhaust gas is turned through 90° by means of guide structures arranged in the exhaust gas inlet connection 4 along the radial direction. flow inward. In this case, the exhaust gas is deflected into a plurality of flow paths 9 , whereby a flow distribution device 8 is realized on the housing surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com